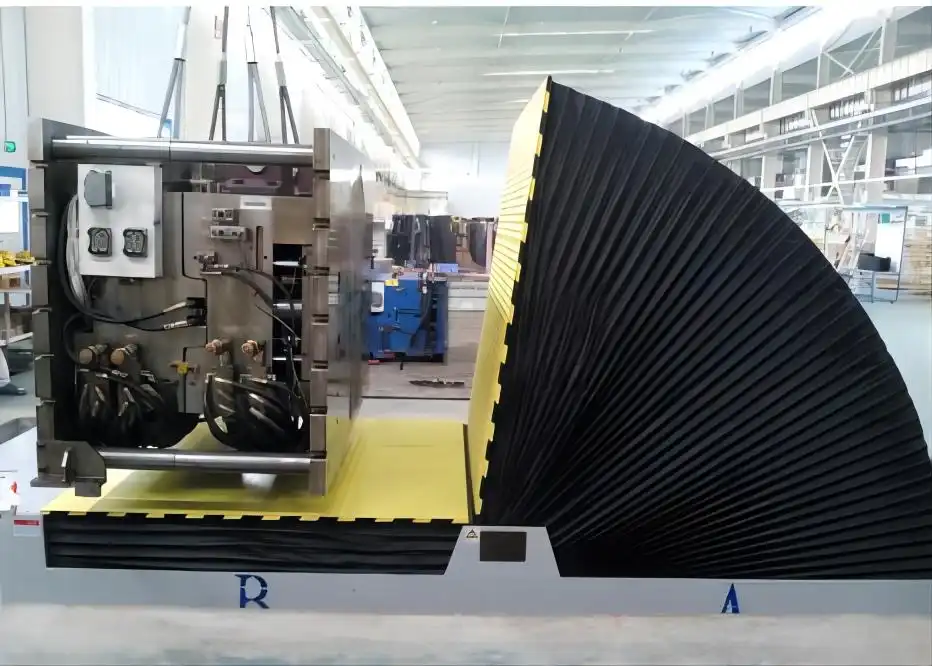

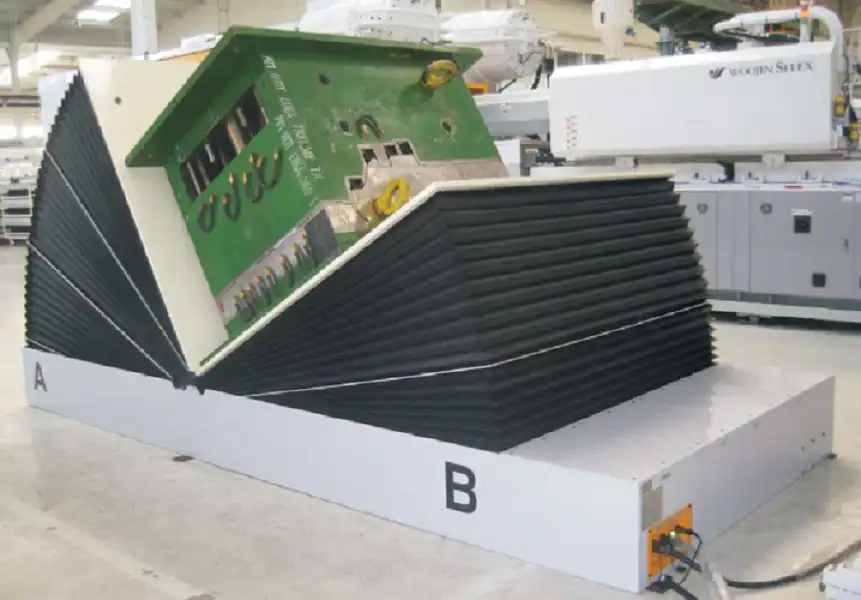

Mold Flipper Table

Project Information

Manual mold handling with cranes is risky and prone to accidents. Mold flippers ensure safe, efficient 90- or 180-degree flipping, keeping operators away from danger.

Key Features

Safety: Limit switches, emergency stops & hydraulic control

Efficiency: Minimizes manual handling & speeds up cycles

Compact Design: Space-saving & layout-flexible

Quality: Certified heavy-duty for 10–100+ ton molds

Transform Your Mold Changeovers

Manual or crane-based mold handling exposes your team to injury, causes delays, and risks damage. The Injection Mold Flipper Table delivers a turnkey hydraulic solution that rotates molds 180° with inverter-driven soft start/stop and dual safety limits—shrinking downtime by up to 40% and keeping operators safely out of harm’s way.

The Challenge: Unsafe, Slow Mold Flips

- Operator Risk: Falling loads and pinch points endanger staff.

- Poor Accuracy: Misaligned stops lead to rework and tool wear.

- Harsh Movements: Sudden starts/stops stress cylinders and molds.

- Footprint Limits: Large setups restrict cell layout options.

The Solution: Key Benefits

- Hands-Free Inversion: 180° hydraulic flip clears operators from moving parts.

- Smooth Motion: Inverter-controlled ramp up/down extends component life.

- Guaranteed Positioning: Mechanical & electronic stops lock at any angle.

- One-Touch Control: Central HMI (with remote option) minimizes exposure.

- Space-Saving Design: Floor-mount or flush pit install fits tight cells.

- Certified Safety: CE-rated guards and emergency stops for total compliance.

Features & ROI

| Feature & Component | Benefit & ROI |

|---|---|

| 180° Hydraulic Flipper | Access all mold surfaces easily—speed up maintenance and inspections. |

| Soft Start/Stop Inverter | Reduce shock loads—extend hydraulic and mold service life. |

| Dual Safety Limits | Prevent over-rotation—ensure reliable, repeatable positioning. |

| Independent Control Panel | Simplify operation—minimize operator training and exposure. |

| Compact Floor-Mount Frame | Integrate into existing cells—optimize cell layout and throughput. |

| CE-Certified Guards | Meet global safety standards—protect staff and equipment. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Injection Mold Flipper Table |

| Rotation | 0–180° (dual 90° segments) |

| Max Load | Up to 40 t (customizable) |

| Drive | Hydraulic cylinders with inverter-controlled pump |

| Soft Start/Stop | Yes (inverter-controlled) |

| Control | Electric panel with remote option |

| Speed Range | Adjustable via inverter |

| Safety Limits | Mechanical stoppers + electronic restrictors |

| Table Size | Custom to mold dimensions (e.g., 2500 × 2500 mm) |

| Power | AC 380 V / 50 Hz / 3‐Phase (other voltages optional) |

| Consumption | 3.7–15 kW (model-dependent) |

| Weight | 2–10 t (model-dependent) |

| Certifications | CE, ISO |

Ideal Applications

- Injection Molding Plants: Fast, safe mold changeovers.

- Die & Mold Shops: Precision flipping for repair & inspection.

- Thermoplastic & Rubber Processing: Handle heavy tooling in tight cells.

- Automotive Components: Reliable inversion for high-volume runs.

- Aerospace & Defense: Safely manage large, delicate molds.

Why Wuxi BuHui?

- Proven Safety: Dual limits & emergency stops exceed global norms.

- Custom Engineering: Tailored sizes & capacities for any mold design.

- Seamless Integration: Compact frame & pit-mount options minimize downtime.

- Robust Reliability: Soft-start hydraulics reduce maintenance needs.

- Full Support: From CAD layout to on-site commissioning and training.

Request Your Quote

Ready to revolutionize your mold handling? Contact Wuxi BuHui today with your mold dimensions and load requirements. We’ll provide detailed drawings, competitive pricing, and a turnkey Injection Mold Flipper Table solution that elevates safety, precision, and throughput.

The Inject Mold flipper table is a specialized equipment designed for 180 degree turning and flipping of molds, dies, and other heavy tools in a safe and efficient operation. It is an essential piece of equipment in the production of molds. The equipment is designed to handle the heavy tools securely and allowing the 180 degree rotation and flipping of the molds, dies and other tools safely.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Mold flipper

The Flipper Lift Table is a machine designed for flipping molding boxes (for mating response to drag or for sand shake of

View Details