Tackling Steel Coil Packing Challenges with Automation

At FHOPEPACK, we understand the complex challenges faced in steel coil packing operations. Our automated steel coil packing and slit coil strapping lines are designed to streamline processes, increase productivity, and improve the overall efficiency of your operations.

Packing Efficiency Bottlenecks

Traditional manual packing processes are unable to meet growing demands. Our automated packing line eliminates these bottlenecks, enabling faster and more reliable packaging for steel coils.

High Operational Costs

Labor-intensive packing methods and material waste can erode your profit margins. Our automatic steel coil packing line reduces labor costs and material consumption, improving your bottom line.

Inconsistent Packing Quality

Manual wrapping results in uneven protection and potential damage during transit. Our automated systems ensure uniform packaging quality, reducing damage and improving reliability.

Workplace Safety Risks

Heavy coil handling poses significant safety risks for workers. Our automatic systems minimize the need for manual intervention, reducing injury risks and improving workplace safety.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Coil packing line Manufacturing Excellence

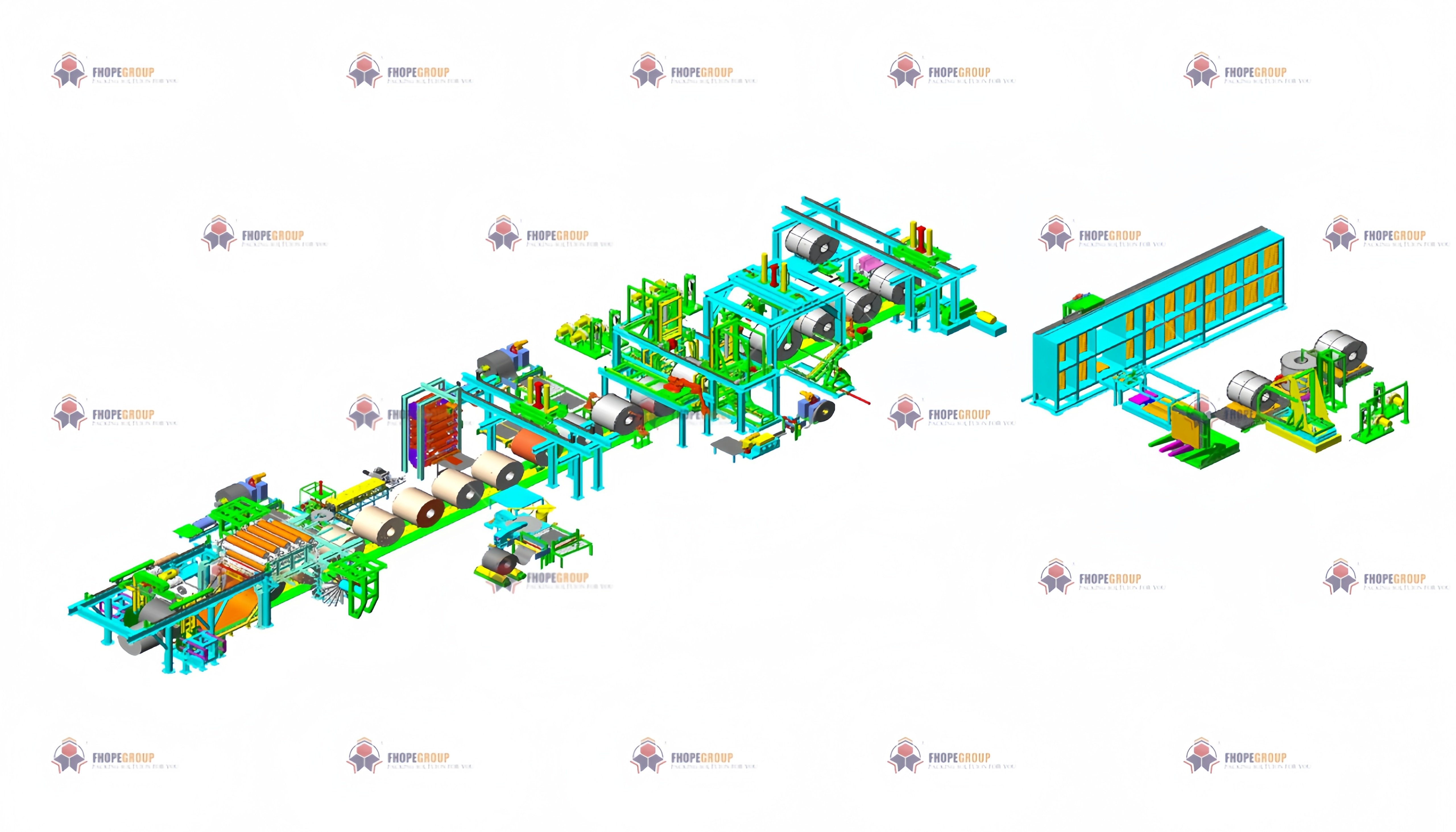

The solution of the steel coil packing line which has aluminum coil pcking system, copper coil packing and stacking system... The solution includes the coil coil, coil wrapping machine, strapping, printer...

Steel coil packing line

Revolutionize your operations with an automated steel coil packing solution designed for efficiency and precision. Discover how our advanced steel coil packing line enhances productivity, ensures safe handling, and reduces operational costs – your key to streamlined manufacturing success.

Copper coil packing line

Streamline your operations with a cutting-edge Copper Coil Packing Line. Discover how an Automated Copper Coil Packaging System enhances efficiency, reduces labor costs, and ensures secure handling. Optimize your production today!

Aluminum coil packing line

An Aluminum Coil Packing Line is a fully automated system designed to streamline the packaging process for aluminum coils. It ensures secure wrapping, strapping, and labeling, protecting coils from damage during storage or transport. This efficient solution enhances productivity, reduces labor costs, and meets industry standards for safe and reliable packaging.

Fully Automated Steel Coil Packing Line

We deliver comprehensive automated steel coil packaging solutions that integrate intelligent control systems with precision mechanical engineering, achieving complete end-to-end automation from loading to finished packaging, dramatically enhancing both efficiency and quality standards.

Complete Process Automation: Integrated automatic feeding, wrapping, film application, strapping, and labeling with zero manual intervention required.

Intelligent Inspection System: Equipped with advanced vision detection and quality control systems ensuring 100% packaging compliance.

Flexible Engineering Design: Accommodates diverse coil specifications from 800-2000mm diameter and 3-20 ton weight capacity.

Packaging Efficiency Increase

Labor Cost Reduction

Packaging Quality Rate

Continuous Production Capability

Major Steel Enterprise Automated Packing Line Transformation

Project Background

Our client, a leading domestic steel production enterprise, relied heavily on manual operations for steel coil packaging, facing challenges of low efficiency, inconsistent packaging quality, and high labor intensity, urgently requiring automation transformation.

Our Engineering Achievement

We designed and implemented a fully automated steel coil packaging production line, achieving complete process automation from coil conveying, automatic centering, inner and outer packaging to finished product discharge. Post-commissioning results: packaging speed reached 12 coils/hour, packaging material savings of 15%, and annual labor cost reduction exceeding $450,000 USD.

Download Complete Case Study

SHOWCASE & NEWS

Steel Coil Packing Line FAQ

Frequently Asked Questions About Automated Steel Coil Packaging Solutions

An automatic steel coil packing line is a fully automated system designed to wrap and secure steel coils for transportation and storage. The process involves automated coil handling, wrapping, strapping, and labeling, ensuring consistent packaging quality and reducing manual labor. It provides greater efficiency, reduces the risk of coil damage, and enhances packaging consistency.

Automatic steel coil packing lines offer several benefits: 1) Increased productivity and faster coil processing, 2) Consistent and precise packaging quality, 3) Reduced labor costs, 4) Improved safety by minimizing manual handling, and 5) Enhanced coil protection during transportation. These systems also reduce material waste and improve operational efficiency.

Our automated packing lines handle a wide range of coil sizes and weights. They can accommodate coils with diameters from 600mm to 2100mm and weights up to 35 tons. Custom configurations are available for mini coils starting at 200mm diameter, and heavy-duty systems can process coils up to 50 tons.

Installation typically takes 8 to 16 weeks, depending on the complexity and customization of the system. This includes site preparation, mechanical and electrical installation, system testing, and operator training. Our expert team ensures a smooth integration with your existing operations, minimizing downtime.

Our packing lines require minimal maintenance. Daily maintenance includes basic cleaning and visual checks. Weekly tasks involve lubricating moving parts and checking consumable levels. Monthly maintenance includes detailed inspections and part replacements as needed. With proper care, our systems can operate for over 15-20 years.

Yes, our packing lines are fully compatible with existing ERP and production systems. We offer seamless integration using standard industrial protocols like OPC-UA and Modbus, ensuring smooth data flow for production orders, inventory tracking, and quality monitoring.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts