Struggling with Heavy Load Positioning Challenges?

Manual handling of heavy coils and materials creates significant operational bottlenecks. Our advanced upender and tilter systems eliminate these inefficiencies while enhancing workplace safety.

Manual Positioning Inefficiency

Time-consuming manual rotation of heavy coils and materials slows down your entire production workflow.

Product Damage During Rotation

Improper handling during material flipping causes surface damage and quality issues in finished products.

Limited Space Utilization

Bulky materials occupying excessive floor space due to inefficient positioning and storage methods.

Worker Safety Concerns

High-risk manual flipping operations expose employees to potential crushing injuries and accidents.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Upender and Tilter Manufacturing Excellence

Discover top-quality coil upenders, coil tilters, mold upenders, and hydraulic upender manufacturers. We offer efficient and reliable hydraulic bending equipment designed to meet your diverse industrial production needs. Enhance your production efficiency by choosing our professional upender solutions, ensuring your production line operates smoothly and effectively.

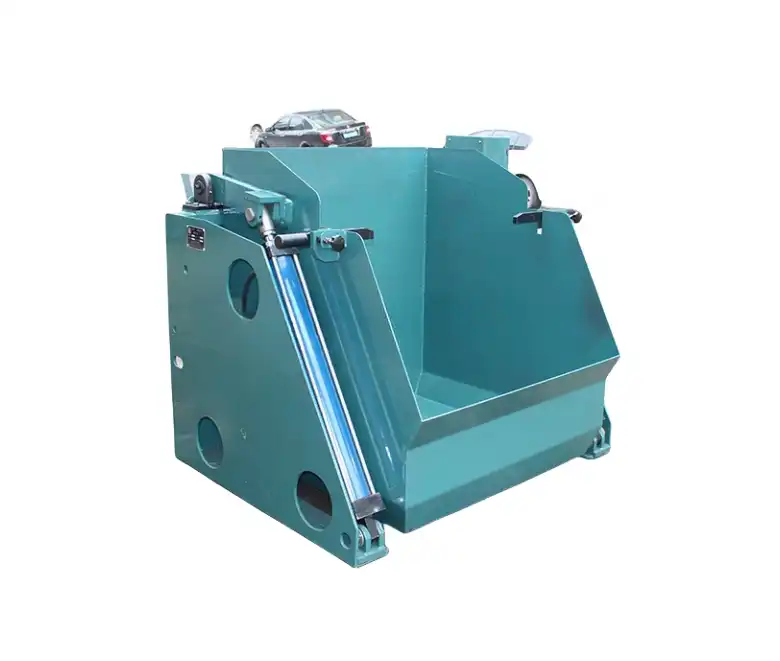

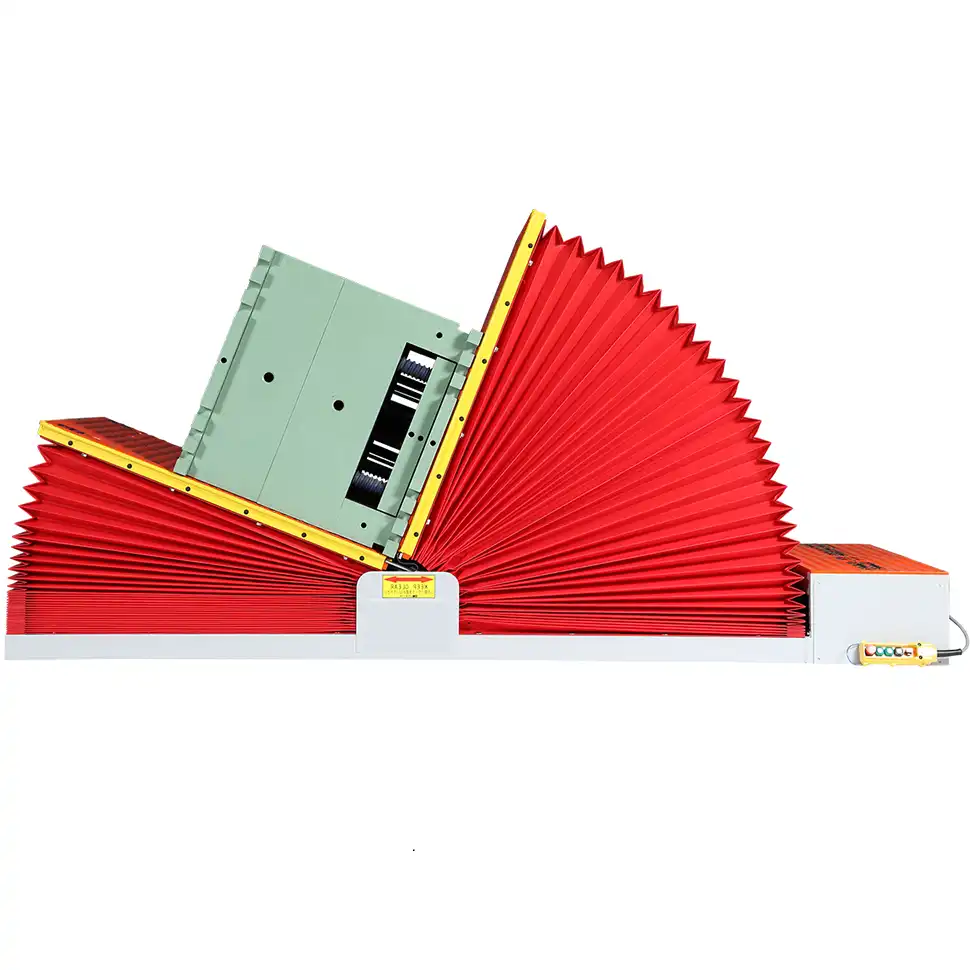

Mechanical upender

Discover affordable solutions for handling heavy materials with our mechanical coil upender, coil tilter, and mold upending machine. Designed for efficiency and safety, these machines simplify operations while reducing costs. Perfect for industries needing reliable equipment without breaking the budget. Upgrade your workflow today with our competitively priced, high-performance machinery tailored

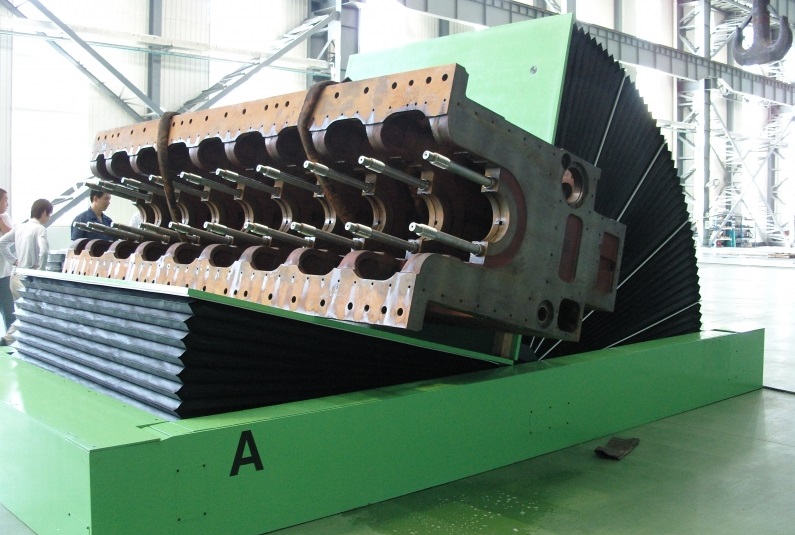

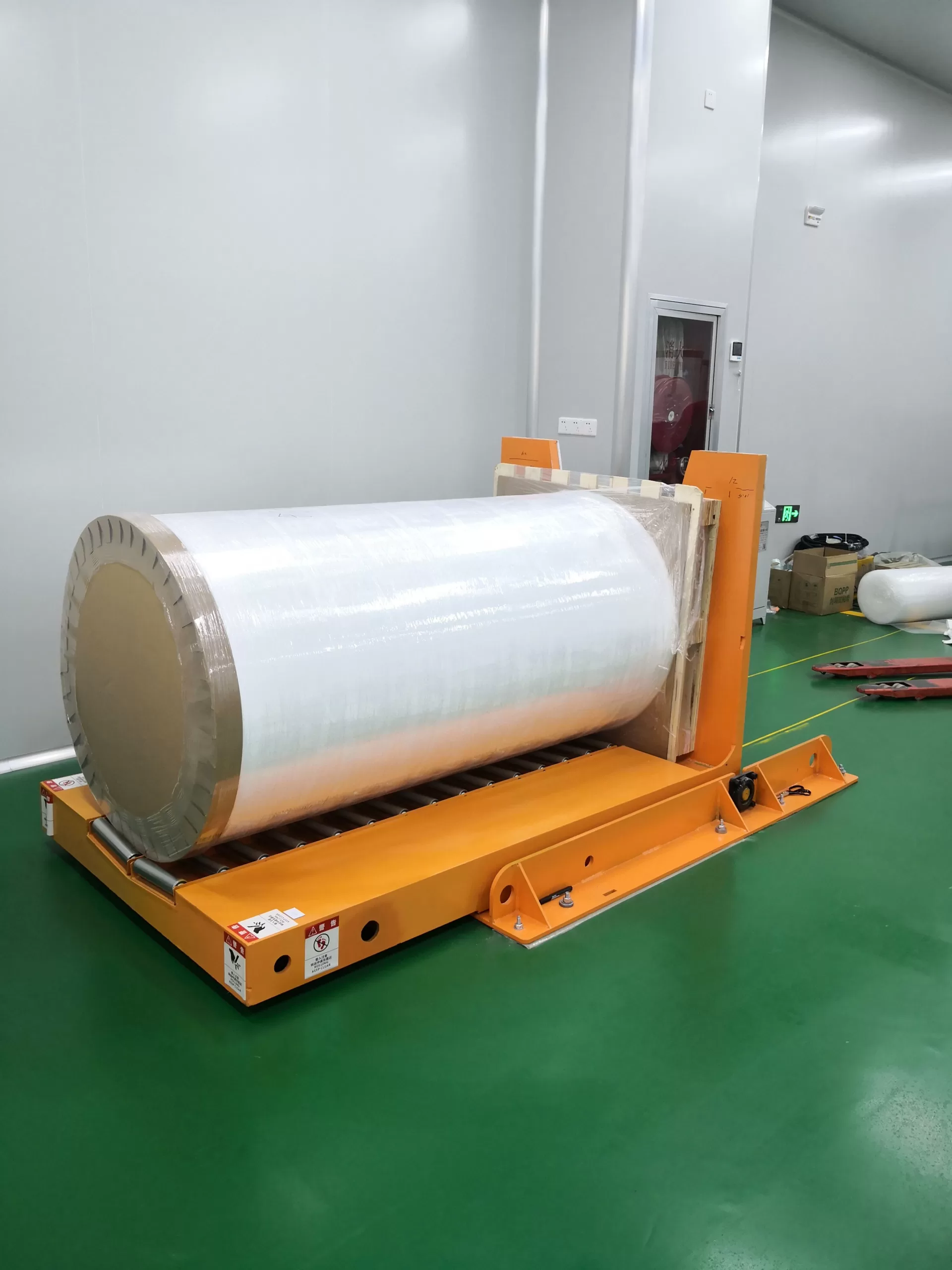

Hydraulic upender

A hydraulic upender is an industrial machine designed to safely and efficiently tilt or rotate heavy loads, such as steel coils, molds, or other bulky items. Using hydraulic power, it ensures precise handling, reduces labor strain, and enhances workplace safety. Its robust construction and customizable features make it ideal for manufacturing, warehousing, and heavy-duty operations.

Coil Upender

Find reliable solutions for heavy material handling with our coil upender, designed to improve efficiency and safety in industrial operations. Partner with a trusted coil upender manufacturer to ensure high-quality, durable equipment tailored to your specific needs. Enhance your workflow today with innovative and cost-effective solutions for your business.

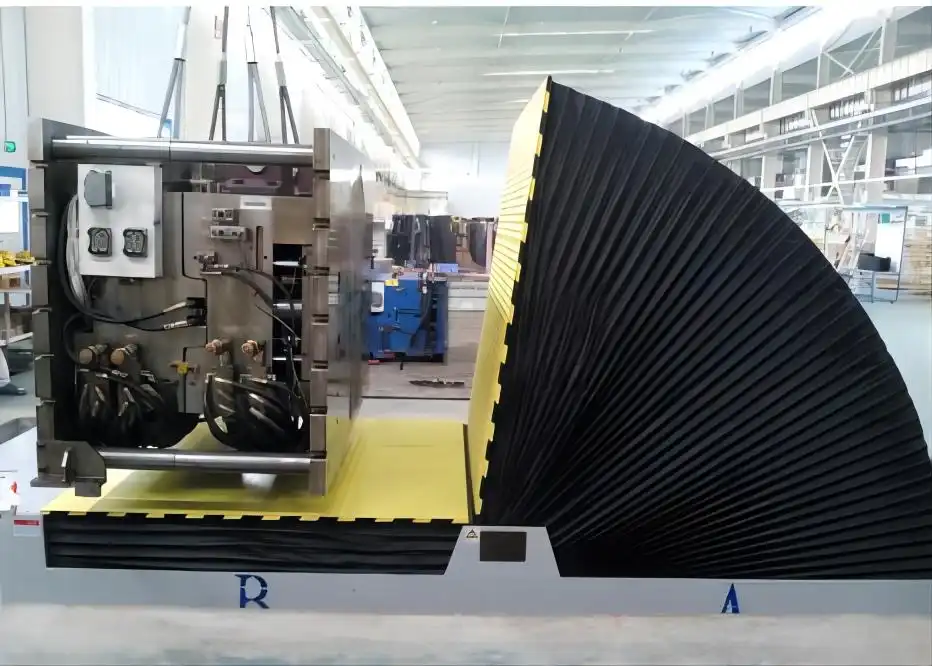

Mold Upender

Enhance your mold handling operations with our mold upender, mold tilter, and mold turning machine. Designed for precision and safety, these machines simplify the process of tilting and rotating heavy molds. Ideal for various industries, they improve efficiency, reduce labor effort, and ensure smooth operations. Invest in reliable, high-performance equipment tailored to your production needs.

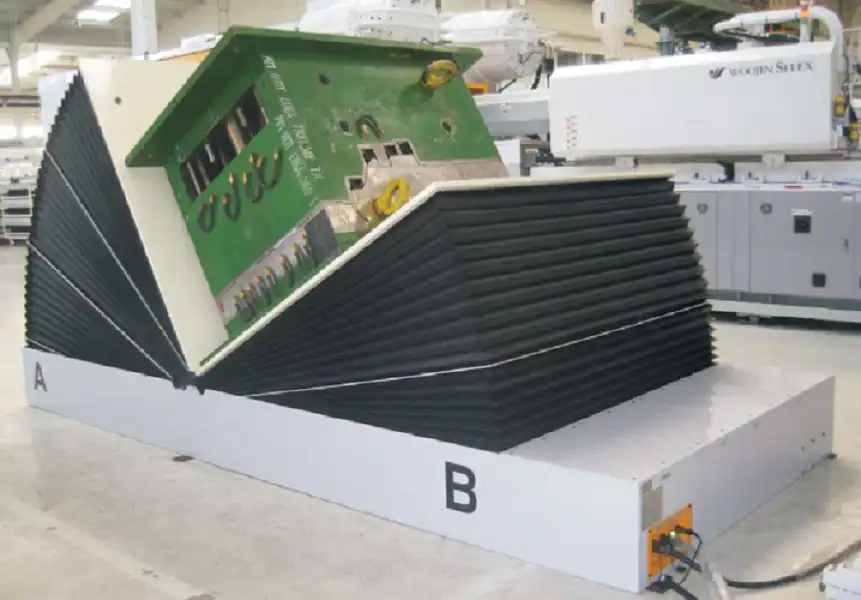

Mold Flipper

A mold flipper is a specialized machine designed to rotate or flip molds safely and efficiently during manufacturing processes. It reduces manual handling, minimizes the risk of damage to molds, and improves workplace safety. With its precise and reliable operation, a mold flipper is essential for industries working with heavy or complex molds.

Hydraulic Dumper

Wuxi BuHui’s Hydraulic Dumper delivers effortless elevation and tipping of heavy boxes and containers—streamlining your workflow, boosting throughput, and enhancing operator safety with smooth, reliable performance.

Precision Load Turning & Positioning Systems

FHOPE Machinery engineers industrial-grade upenders and tilters that deliver precise load manipulation across multiple sectors. Our robust turning equipment ensures seamless material reorientation while maintaining maximum operational safety and equipment longevity.

Multi-Industry Compatibility: Engineered for steel coils, aluminum rolls, copper foils, and industrial molds with customized clamping mechanisms.

Hydraulic Precision Control: Smooth 90°-180° rotation with programmable positioning accuracy within ±1° for delicate materials.

Safety-Integrated Design: Automated locking pins, overload protection, and emergency stop systems ensure zero-incident operation.

Faster Material Turnover

Operation Safety Record

Energy Consumption Saved

Global Installations

Heavy-Duty Upender Transformation in Aluminum Processing

Operational Challenge

A leading aluminum manufacturer faced consistent material handling bottlenecks with their 5-ton coils. Manual turning operations caused surface damage and production delays, requiring a automated solution for their rolling mill operations.

Engineering Breakthrough

FHOPE implemented a custom 180° hydraulic upender with protective lining. The solution eliminated product damage while achieving 15 cycles/hour turnover rate. The automated system reduced manpower requirements by 75% and increased overall production throughput by 40% within six months.

Request Custom Solution

SHOWCASE & NEWS

Industrial Upender and Tilter Solutions FAQ

Expert Answers to Your Material Handling and Load Turning Questions

Our material turning equipment serves multiple industrial sectors with specialized handling needs. Key applications include steel coil processing, wire manufacturing, aluminum and copper foil production, mold handling, and wheel slide valve operations. These machines are particularly valuable in metal processing facilities across North America, Europe, and Asian markets where heavy load manipulation is routine. The versatility of our turning solutions makes them ideal for manufacturing plants requiring precise material positioning for subsequent processing or packaging stages.

Industrial upenders significantly enhance both safety protocols and operational productivity. They eliminate manual handling of heavy loads, reducing workplace injuries by up to 85% according to industry data. These machines ensure precise load positioning, minimizing product damage during rotation tasks. Operational efficiency improves through reduced turnaround time - our systems can complete full rotation cycles in under 60 seconds. The automated handling also allows for continuous operation in demanding environments, maintaining consistent performance while protecting valuable materials from improper handling damage.

FHOPE Machinery provides three primary turning solutions: pallet turning machines for standard unit loads, mechanical turning systems for high-speed operations, and hydraulic turning machines for heavy-duty applications. Our pallet flippers handle loads up to 5 tons with precise 90-180 degree rotation capability. Mechanical turners offer the fastest cycle times for production lines, while hydraulic systems provide the highest power capacity for industrial-grade applications up to 35 tons. Each machine type incorporates specialized clamping mechanisms and control systems tailored to specific material handling requirements.

Absolutely. Our engineering team specializes in developing custom flip systems tailored to unique load specifications. We consider factors including load weight distribution, center of gravity, material surface sensitivity, and existing facility layout. Customization options include specialized clamping interfaces, variable rotation speeds, programmable positioning controls, and integration with conveyor systems. With two decades of design experience, we've created solutions for unusual shaped loads, fragile materials, and challenging operating environments. Our global client base benefits from this adaptability across diverse industrial applications.

Our upender systems require minimal but regular maintenance to ensure long-term reliability. Daily visual inspections (5-10 minutes) check for obvious issues. Weekly maintenance includes hydraulic system checks and structural component inspection. Monthly service involves lubrication of moving parts and electrical system verification. We provide comprehensive maintenance manuals and optional remote monitoring services that predict 92% of potential failures before they cause downtime. With proper care, FHOPE turning machines typically operate for 15+ years in demanding industrial environments while maintaining precision performance.

FHOPE Machinery offers the industry's most extensive range of load turning solutions, outperforming competitors in several key areas. Our machines incorporate 20 years of engineering refinement, resulting in 30% better energy efficiency than industry averages. We provide broader load capacity ranges (200kg to 35 tons) and more customization options than standard suppliers. Global clients choose us for our reliable performance in continuous operation environments and advanced safety features that exceed international standards. The proven durability of our systems has established our reputation across six major industrial sectors worldwide.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts