Revolutionize Your Wire Coil Packaging Efficiency

Experience next-generation wire winding and strapping technology that eliminates production bottlenecks while ensuring maximum operator safety and packaging consistency.

Automated Winding Precision

Our automatic wire coiler systems deliver consistent coil formation with precision tension control for perfect bundles every time.

Cost-Effective Operation

Reduce labor costs by up to 70% with fully automated wire strapping and packaging processes that minimize material waste.

Enhanced Safety Features

Non-contact operation and secure unloading mechanisms protect your workforce while handling heavy wire coils and packaging materials.

CE Certified Performance

All our horizontal and vertical wire coiler models meet strict CE certification standards for reliable operation in global markets.

Join manufacturers worldwide who trust Fhope's automatic wire winding solutions to streamline their packaging operations and boost productivity.

Request Your Custom Solution

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Automatic wire packing line Manufacturing Excellence

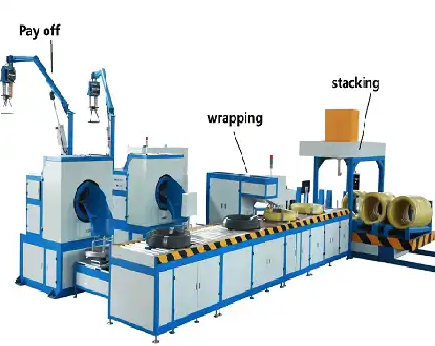

The Automatic Wire Packing Line is an advanced solution designed to streamline wire coil packaging processes. Featuring high-speed automation, precision wrapping, and customizable configurations, it enhances productivity and ensures secure packaging. Ideal for diverse industries, it reduces labor costs, minimizes material waste, and guarantees consistent quality for efficient wire handling.

Wire winding and packing line

The solution of the Automatic steel wire rewinding and packaging lines that includes the wire rewiding, wire strapping, wire coil wrapping and package stacking. The solution is customzied per different steel wire factory

Wire compacting and strapping line

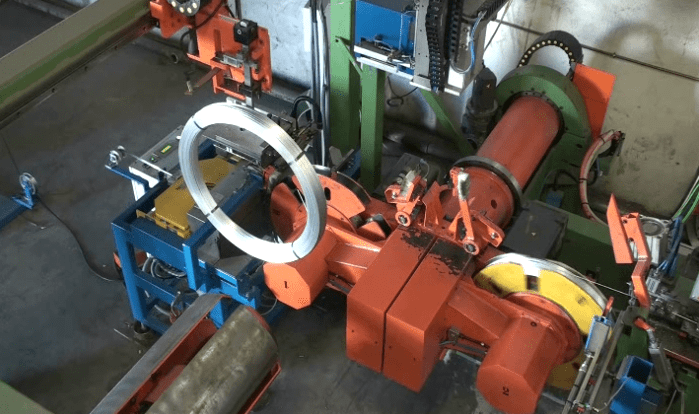

A Wire Compacting and Strapping Line is a specialized system designed to compact and securely strap wire coils or bundles. It ensures precise alignment, efficient compression, and durable strapping for easy handling and transport. This automated solution enhances productivity, reduces labor costs, and guarantees safe and reliable packaging for industrial wire products.

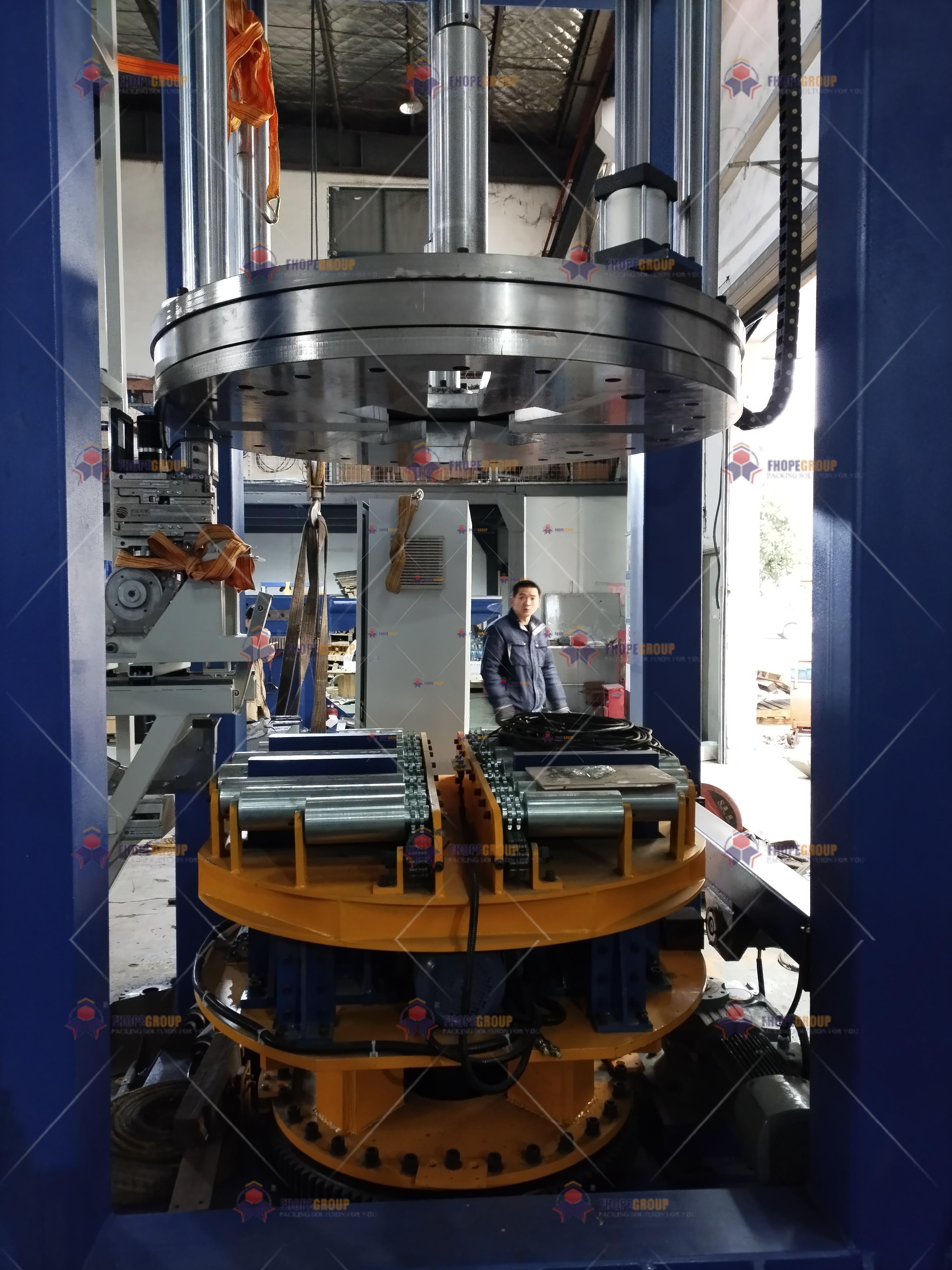

Precision Automatic Wire Coiling & Packaging Systems

Fhope's automatic wire coilers deliver exceptional winding precision and secure strapping performance, featuring advanced non-contact operation technology that ensures maximum operator safety while maintaining consistent production output for various wire materials.

Dual-Orientation Design: Available in both horizontal and vertical configurations to suit different factory layouts and production requirements.

Safety-First Operation: Non-contact winding technology and automated unloading systems eliminate manual handling risks.

Certified Compliance: Full CE certification and adherence to international industrial safety standards for global deployment.

Faster Coiling Speed

Operation Safety

Space Optimization

Global Installations

Wire Manufacturing Facility Automation Upgrade

Production Challenge

A European wire manufacturer struggled with inconsistent coil quality and high labor costs due to manual winding processes. Their existing equipment caused wire damage and failed to meet increasing production demands.

Automated Solution

Fhope implemented a customized automatic wire coiling system that streamlined their entire packaging line. The solution included precision tension control, automated strapping, and gentle handling mechanisms, resulting in perfect coil formation and reduced material waste.

Request Custom Solution

SHOWCASE & NEWS

Automatic Wire Coiler FAQ

Frequently Asked Questions About Advanced Wire Winding and Packaging Systems

Automatic wire coilers significantly enhance packaging efficiency through streamlined wire winding and strapping processes. These advanced systems can process up to 40 coils per hour with consistent tension control and precise winding patterns. The non-contact operation eliminates manual handling risks while maintaining optimal production flow. With customizable programming options, our coilers adapt to various wire types and diameters, reducing changeover time by 60% compared to manual methods.

Our automatic wire coilers incorporate comprehensive safety systems including emergency stop buttons, safety light curtains, and overload protection mechanisms. The equipment features non-contact operation that minimizes operator interaction with moving parts. All machines comply with CE safety guidelines and include automatic fault detection systems. The safe unloading mechanism prevents coil collapse during transfer, while the enclosed design protects operators from wire ends and moving components.

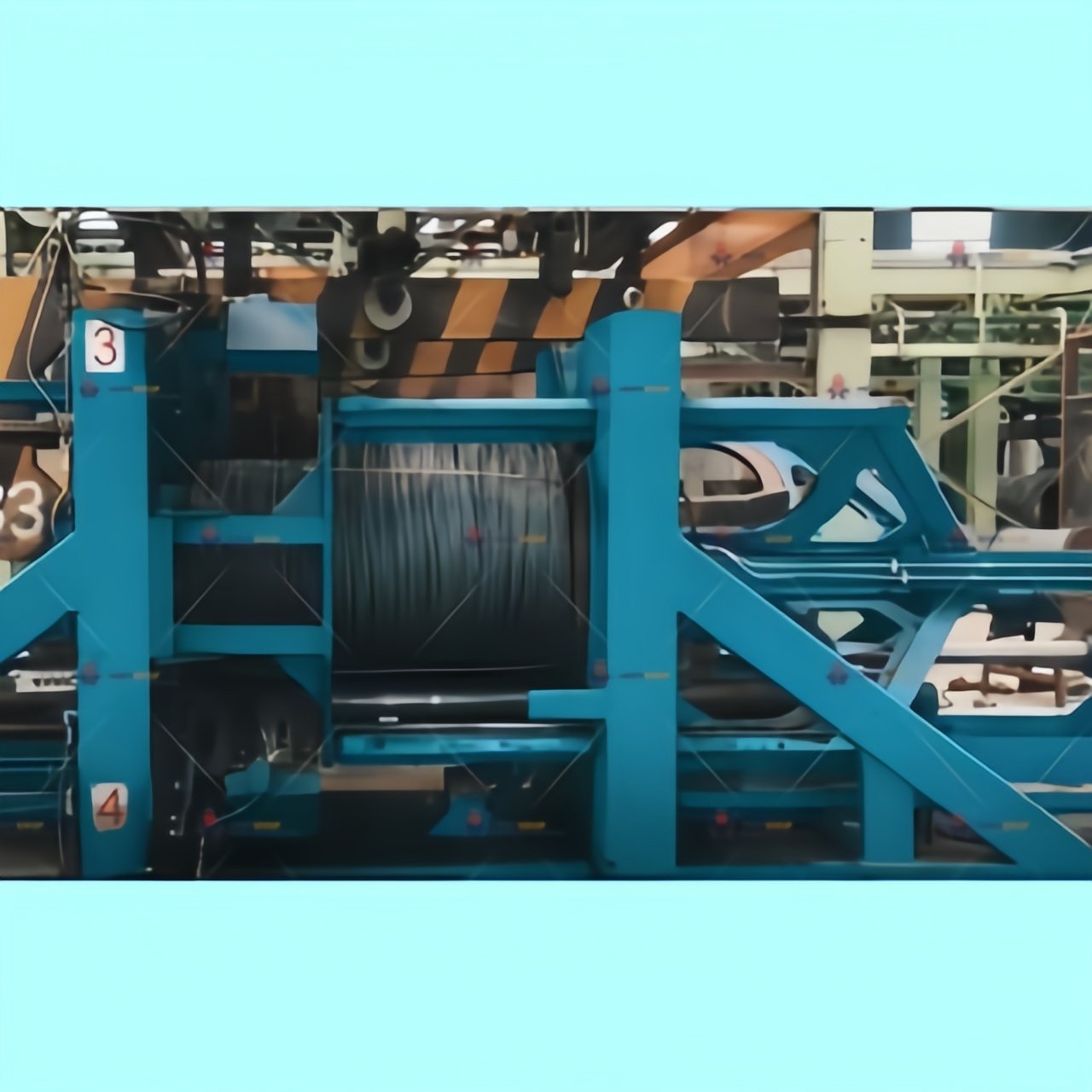

Fhope automatic wire coilers accommodate diverse wire materials including steel, copper, aluminum, and specialty alloys. Standard models handle wire diameters from 1.5mm to 12mm and produce coil weights up to 2,000 kg. Both horizontal and vertical winding configurations are available, with coil diameters ranging from 800mm to 1,600mm. Customizable tension control systems ensure optimal winding for different material properties and surface finishes.

The integrated automatic strapping system works seamlessly with the coiling process to provide complete packaging solutions. After winding completion, the system automatically applies steel or plastic strapping at predetermined positions with consistent tension. This integrated approach eliminates secondary handling and reduces total packaging time by up to 45%. The strapping heads can be configured for single or multiple strap applications, with tension adjustment capabilities for different coil densities.

Fhope provides comprehensive maintenance support including detailed operation manuals, video tutorials, and remote assistance capabilities. We offer on-site training for your operators covering daily operations, routine maintenance, and troubleshooting procedures. Our service packages include scheduled maintenance visits, spare parts management, and 24/7 technical support. The equipment features self-diagnostic systems that alert operators to potential issues before they cause downtime.

Absolutely. Fhope specializes in customizing wire coiling solutions to match unique production environments. We can modify coil dimensions, integrate with existing conveyor systems, add specialized strapping patterns, or incorporate quality control sensors. Our engineering team works closely with clients to develop tailored solutions that address specific material handling needs, space constraints, and output targets. Custom automation features like barcode labeling and data tracking can also be integrated.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts