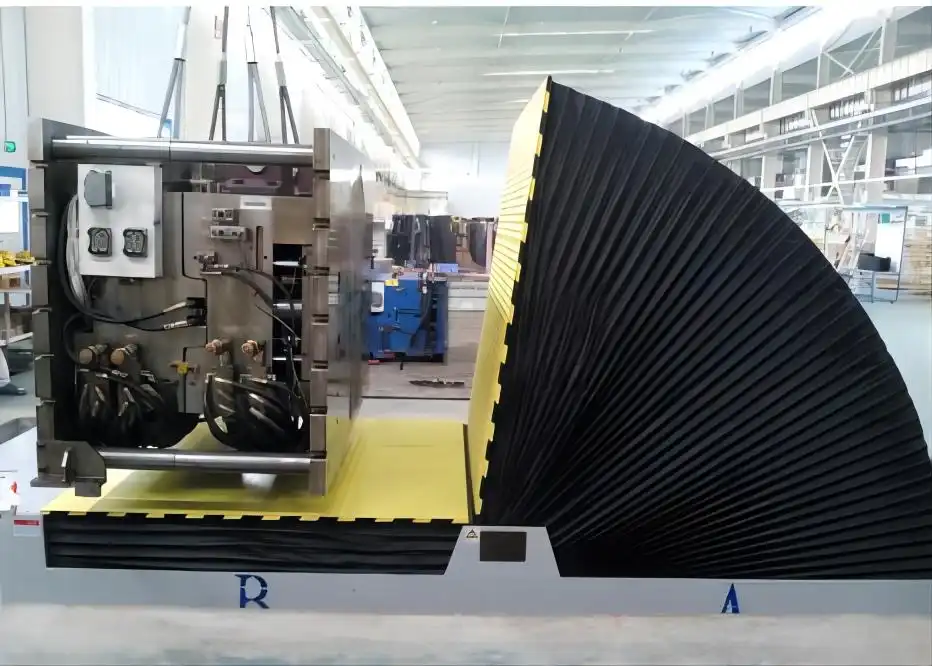

90 Degree Mold Upender 20T

Project Information

The 90 Degree Mold Upender 20T is designed for safe and efficient handling of heavy molds up to 20 tons. With its durable construction, advanced hydraulic system, and comprehensive safety features, it ensures smooth operation and enhanced productivity across industries like automotive manufacturing, plastic injection molding, and heavy machinery fabrication.

Maximum Load Capacity: 20 tons (20,000 kg)

Motor Power: 7.5 kW

Table Dimensions: 3500 × 2500 × 550 mm

Rotation Angle: 90 degrees

Wuxi BuHui’s 90° Mold Upender 20T delivers a controlled hydraulic flip for molds up to 20 tons—streamlining changeovers, protecting tooling and keeping operators safe.

The Challenge: Heavy Mold Handling Risks

- Safety Hazards: Manual lifts and rotations endanger staff.

- Downtime Delays: Slow, imprecise repositioning prolongs changeovers.

- Tool Damage: Inconsistent handling risks costly repairs.

- Capacity Limits: Standard upenders struggle above 10 tons.

The Solution: Features & Benefits

| Feature | Benefit / ROI |

|---|---|

| 20 T Hydraulic Drive | Effortless flips of the heaviest molds—eliminates manual lifting |

| Precise 90° Rotation | Consistent positioning on first try—cuts changeover time by up to 50% |

| High-Tensile Steel Frame | Built to last in harsh environments—maximizes uptime and ROI |

| Manual & PLC Control | Fits varied workflows—minimizes training and integration time |

| Safety Locks & Overload Protection | Guards operators and equipment—meets strict safety standards |

| Custom Table Dimensions | Adapts to your molds—avoids costly facility modifications |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | FPMT-20 |

| Max Load | 20 tons (20 000 kg) |

| Rotation Angle | 90° full flip |

| Table Size | 3 500 × 2 500 × 550 mm |

| Motor Power | 7.5 kW |

| Hydraulic Oil | 15 L capacity |

| Controls | Manual + PLC interface |

| Safety | E-stop, overload protection, mechanical locks |

| Frame | High-tensile industrial steel |

Ideal Applications & Industries

- Automotive Mold Shops: Rapid tool changes for stamping dies

- Aerospace Composite Molding: Precise rotation of large layup molds

- Injection Molding: Streamlined flips for multi-ton tooling

- Heavy Equipment Manufacturing: Safe handling of cast and forged molds

Why Wuxi BuHui?

Our upender combines robust 20 T hydraulics, pinpoint 90° accuracy and full safety interlocks—delivering fast, repeatable flips that protect your team and your molds while boosting productivity.

Request a Quote

Ready to elevate safety and efficiency? Request a quote today to tailor the 90° Mold Upender 20T to your production needs.

The 90 Degree Mold Upender 20T is a robust and efficient machine designed for safely flipping heavy molds up to 20 tons. It enhances operational efficiency, reduces manual handling risks, and ensures precision in mold positioning. Ideal for industrial environments, it offers durability, reliability, and ease of use for streamlined workflows.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Die and Mold Turner

A die and mold turner is a specialized machine designed to safely and efficiently rotate heavy dies and molds. It enhance

View Details180 Degree Mold Upender 5T

The 180 Degree Mold Upender 5T is a robust and efficient solution designed to safely and seamlessly rotate heavy molds up

View Details180 Degree Mold Upender 20T

The 180 Degree Mold Upender 20T is a heavy-duty machine designed to safely and efficiently rotate molds or materials up t

View Details90 Degree Mold Upender 5T

The 90-Degree Mold Upender 5T is a reliable and efficient solution for safely tilting heavy molds up to 5 tons. Designed

View Details90 Degree Mold Upender 40T

The 90-degree mold upender 40T is a reliable industrial machine designed to rotate heavy molds up to 40 tons with precisi

View Details90 Degree Mold Upender 10T

A 90-degree mold upender with a 10-ton capacity is an industrial solution designed for safe and efficient handling of hea

View Details