Mold Flipper for 40T

Project Information

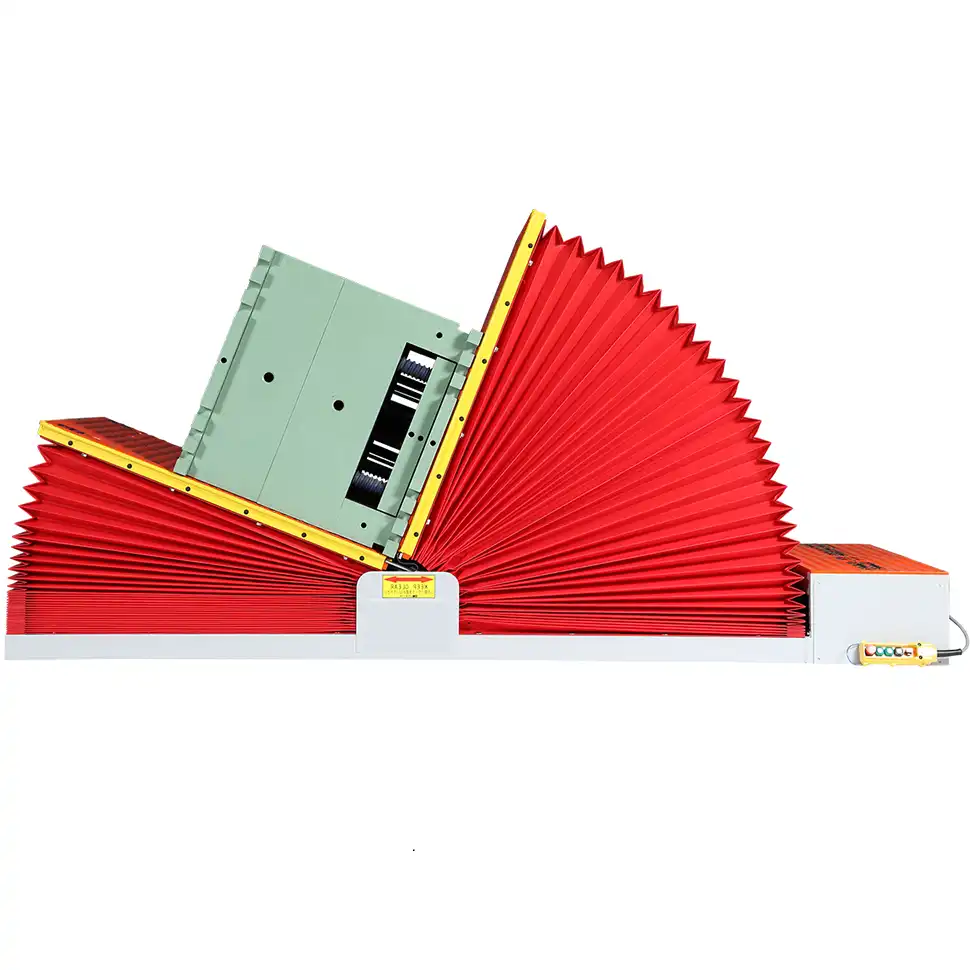

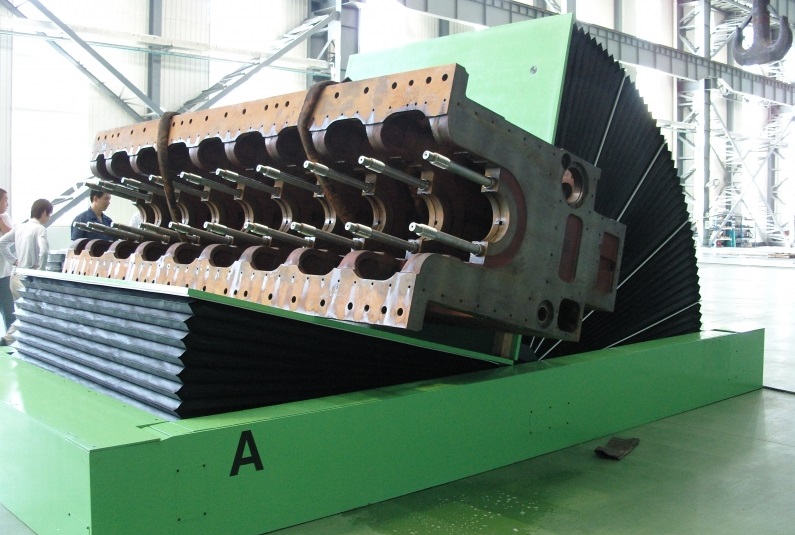

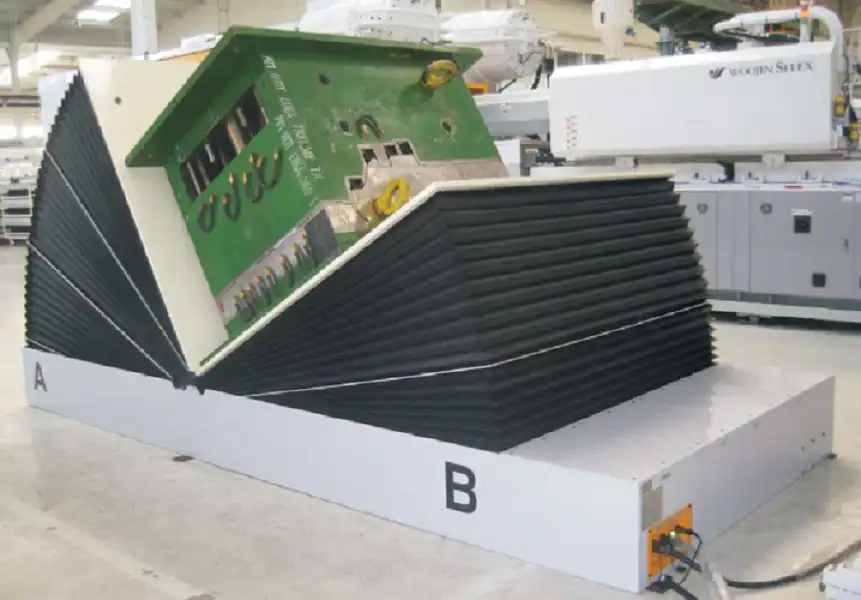

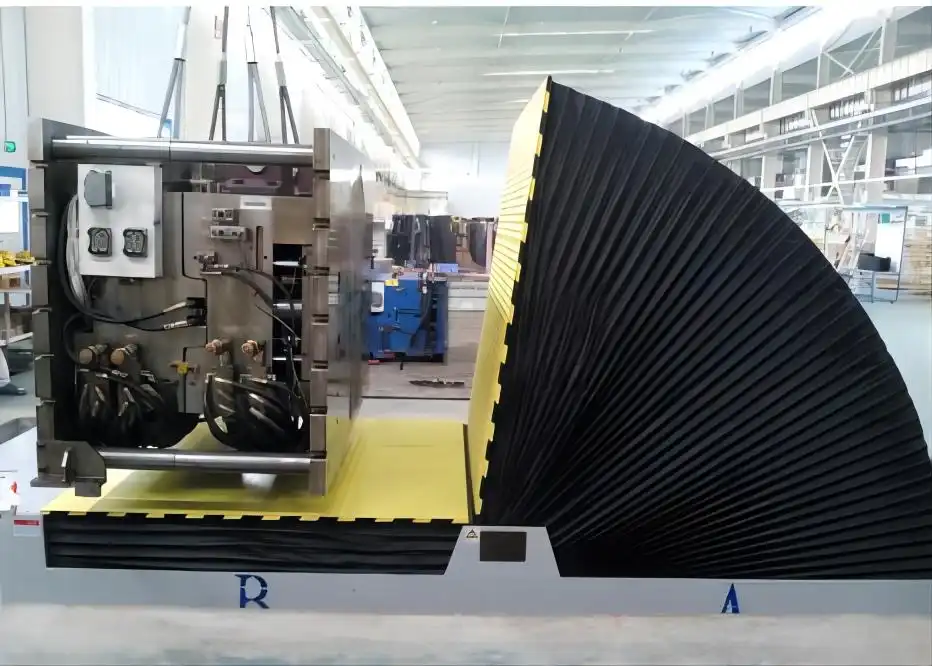

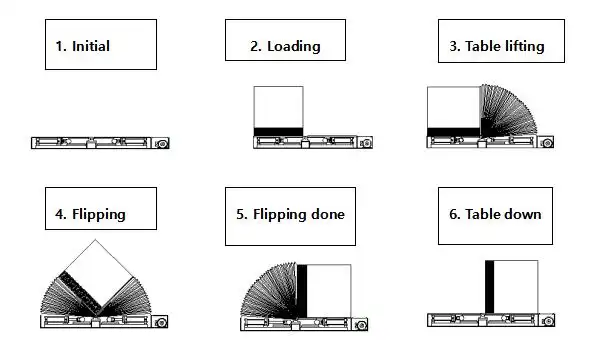

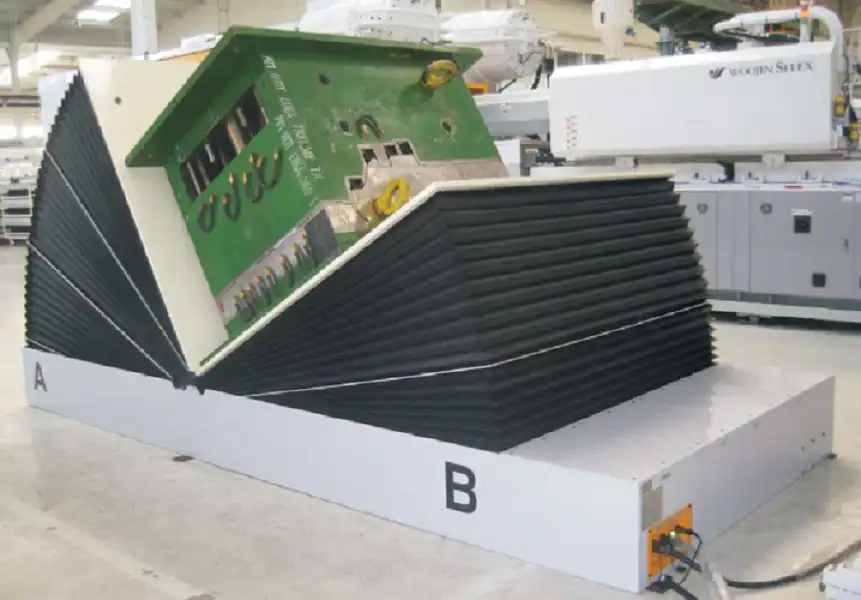

The Mold Flipper for 40T is designed to handle molds weighing up to 40 tons with precision and safety. Equipped with a hydraulic system and advanced safety features, it ensures efficient flipping, reduces manual labor, and minimizes downtime. This machine is an essential tool for improving productivity and safety in heavy industrial operations.

Model Type: FPMT-40

Maximum Load Capacity: 40 Tons (40,000 Kg)

Motor Power: 7.5 kW

Table Dimensions (L × W × H): 4500 × 2400 × 500 mm

Maximum Rotation Angle: 180 Degrees

In large-scale molding operations, every minute of downtime costs money. Wuxi BuHui’s 90° Mold Flipper 40T automates precise 90° rotations of molds up to 40 t—cutting changeover time, eliminating crane use, and keeping your team safely clear.

The Challenge

- Extended Changeovers – Manual lifts and cranes slow production.

- Safety Hazards – Uncontrolled flips risk injury and damage.

- Inconsistent Positioning – Misalignment causes scrap and rework.

Features & Benefits

| Feature | Customer Benefit |

|---|---|

| 40 T Hydraulic Drive | Flips heaviest molds effortlessly—no cranes needed |

| Precision Control & Position Lock | Repeatable 90° alignment—reduces scrap and setup time |

| Safety Interlocks & E-Stop | Instant shutdown and multi-layer protection for personnel |

| Robust Steel Frame & Cast-Iron Pump | Industrial-grade durability—minimizes maintenance costs |

| Adjustable Rotation Speed | Syncs with your production schedule—boosts throughput |

| User-Friendly Controls | Panel or PLC interface—rapid training and integration |

Technical Specifications

| Specification | Details |

|---|---|

| Model | FPMT-40 |

| Capacity | 40 000 kg (40 t) |

| Rotation Angle | 90° |

| Table Size (L×W×H) | 4 500×2 400×500 mm |

| Motor Power | 7.5 kW |

| Hydraulic Oil | 15 L cast-iron pump |

| Control | Manual panel & PLC option |

| Safety | Interlocks & emergency stop |

Ideal Applications & Industries

- Automotive Tooling – Rapid mold changeovers for high-volume runs

- Aerospace Composites – Precise flip of large tool assemblies

- Heavy Plastics Injection – Safe handling of multi-ton molds

- Rubber & Elastomers – Consistent orientation for curing presses

Why Wuxi BuHui?

- Unmatched Power – Industry-leading 40 T hydraulic drive for the toughest molds.

- Repeatable Accuracy – Position lock and precision controls ensure exact alignment every time.

- Comprehensive Safety – Multi-layer interlocks and E-Stop protect your team.

- Low Maintenance – Robust construction and quality components reduce downtime.

Request a Quote

Transform your mold changeovers with the 90° Mold Flipper 40T. Contact Wuxi BuHui with your mold specs and workflow needs for a custom solution, detailed drawings, and competitive pricing.

The Mold Flipper for 40T is designed to handle heavy molds up to 40 tons, offering efficient and precise mold flipping. Equipped with a hydraulic drive system and safety features, it ensures smooth operation, minimal downtime, and increased productivity, making it ideal for large-scale manufacturing and industrial applications.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

90 Degree Mold Flipper for 10T

The 90 Degree Mold Flipper for 10T is a compact and efficient solution for handling molds weighing up to 10 tons. It enab

View DetailsMold Flipper for 30T

The Mold Flipper for 30T is a powerful tool engineered to handle molds up to 30 tons with ease. Featuring advanced safety

View DetailsMold Flipper for 20T

The Mold Flipper for 20T is a robust industrial solution designed to safely and efficiently rotate heavy molds weighing u

View DetailsMold Flipper for 10T

A mold flipper for 10T is an industrial machine designed to rotate heavy molds weighing up to 10 tons with precision and

View DetailsMold Flipper for 5T

A mold flipper for 5T is a robust and efficient machine designed to handle heavy molds weighing up to 5 tons. It streamli

View DetailsMold Flipper for 2T

A mold flipper for 2T is a specialized industrial machine designed to safely and efficiently rotate molds weighing up to

View Details