Tired of Inefficient Steel Coil Packaging?

Discover how our automated coil packing systems eliminate production bottlenecks while ensuring superior protection for your valuable steel coils during transit and storage.

Automated Coil Wrapping System

Our precision-engineered coilers automatically wrap wire around fixed bobbins with consistent tension and alignment for perfect coils every time.

Non-Contact Operation

Advanced non-contact transfer systems ensure smooth material handling while eliminating operator safety risks and reducing maintenance costs.

Front-Load Safety Design

Safely unload finished pipe coils from the front side with protected access doors that separate operators from active winding operations.

Flexible Configuration Options

Choose from multiple configurations including longitudinal guides or castor systems with dual line directions to match your production layout.

Join leading steel manufacturers who have reduced packaging costs by up to 40% while eliminating coil damage during shipping.

Request Your Custom Solution

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Automatic wire coiler Manufacturing Excellence

The manuracturer provides sthe automatic wire winding and strapping solutions: wire coiling and wrapping, strapping machines. Online or offline automation wire coil packing process...

Coil packing line

The solution of the steel coil packing line which has aluminum coil pcking system, copper coil packing and stacking system... The solution includes the coil coil, coil wrapping machine, strapping, printer...

Orbital stretch wrapper

Fhope Machinery, a professional manufacturer of packaging equipment, can customize horizontal winding packaging machine solutions for you. The equipment can achieve good packaging effect, high efficiency, easy operation, affordable price and high machine stability. Is an excellent choice for your product packaging.

Coil wrapping machine

Heavy-duty, High Speed Coil wrapping machine manufactured by FHOPEPACK,one of a leading manufacturer of Coil packaging Equipment for different coil shape products, such as steel coil, wire coil, hose, pipe, bearing,tyre...

Automatic wire packing line

The Automatic Wire Packing Line is an advanced solution designed to streamline wire coil packaging processes. Featuring high-speed automation, precision wrapping, and customizable configurations, it enhances productivity and ensures secure packaging. Ideal for diverse industries, it reduces labor costs, minimizes material waste, and guarantees consistent quality for efficient wire handling.

Automatic wire coiler

The manuracturer provides sthe automatic wire winding and strapping solutions: wire coiling and wrapping, strapping machines. Online or offline automation wire coil packing process...

Automatic pipe coiler

Automatic hose and pipe coiler and strapping machine line manufacutrer in China helps you find the automation solution after extruding machine with good price. Not man required for coiling process anymore...

Automatic cable coiler

Automatic cable coiling and packing solutions provides by Fhopepack: automatic cabe coiler and wrapper, cable winding machine and strapping machine, cable coiling and shrinking machine, cable coil stacking machine...

Upender and Tilter

Discover top-quality coil upenders, coil tilters, mold upenders, and hydraulic upender manufacturers. We offer efficient and reliable hydraulic bending equipment designed to meet your diverse industrial production needs. Enhance your production efficiency by choosing our professional upender solutions, ensuring your production line operates smoothly and effectively.

Pallet Inverter

Efficiently streamline material handling with our Pallet Inverter and Pallet Changer solutions. Designed for safety, durability, and precision, these systems simplify pallet rotation and replacement, reducing labor costs and minimizing product damage. Ideal for warehouses, logistics, and manufacturing industries. Explore customizable options to meet your specific needs.

Automatic Wire Winding and Packing Machine

The solution of the Automatic steel wire rewinding and packaging lines that includes the wire rewiding, wire strapping, wire coil wrapping and package stacking. The solution is customzied per different steel wire factory

Auto Bagger

The development of the autobagger, bagging machine and other specialized bagging equipment demonstrates the company's commitment to meeting the diverse needs of its clients in bagging and printing.

Door Packaging Machine

The door packing solution include the automatic door wrapping machine, door shrinking machine and door handling system

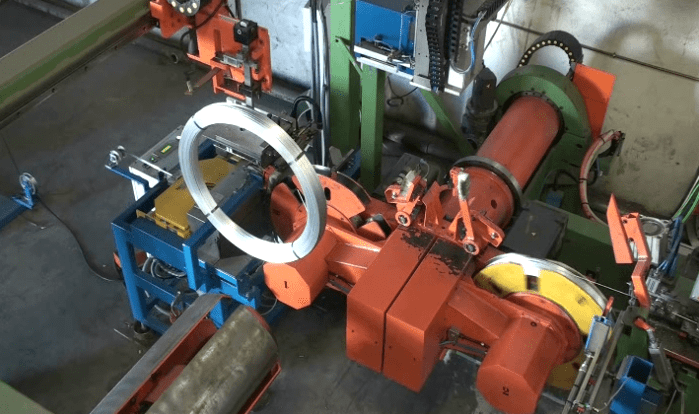

Precision Automatic Wire Coiling System

Our innovative automatic coiler delivers exceptional wire winding precision with complete operator safety. Engineered for seamless wire transfer and secure front-side pipe coil unloading, this system revolutionizes industrial coiling operations.

Safe Front Unloading Design: Protected unloading door system ensures operator safety while maintaining access to finished coils from the machine front.

Dual Direction Flexibility: Features longitudinal guide or castor options with two line directions for versatile production layouts.

Non-Contact Operation: Smooth wire transfer mechanism eliminates contact issues, ensuring consistent coil quality and reduced maintenance.

Faster Operation Cycle

Operator Safety Guarantee

Coiling Precision Rate

Energy Consumption Reduction

Wire Manufacturing Plant Automation Upgrade

Production Challenge

A prominent European wire manufacturer struggled with manual coiling processes that caused inconsistent tension, frequent wire breakage, and operator safety concerns. Their existing equipment couldn't handle varying wire diameters efficiently.

Automation Solution

We implemented our precision automatic coiling system with advanced tension control and safety-shielded unloading. The results: production output increased by 60%, material waste reduced by 25%, and achieved zero safety incidents since installation.

Request Technical Specifications

SHOWCASE & NEWS

Automatic Coiler Machine FAQ

Frequently Asked Questions About Automated Wire Coiling Systems

Our automatic coiler incorporates multiple safety features including non-contact operation, protective shielding, and front-side unloading. The machine design physically separates operators from the winding mechanism while allowing safe access for coil removal. The unloading door provides a protective barrier during operation, ensuring complete operator safety while maintaining efficient workflow and productivity.

The automatic coiler processes various wire types including copper, aluminum, steel, and specialty alloys with diameters ranging from 0.5mm to 8mm. The system accommodates different bobbin sizes and can handle wire tensile strengths up to 1200 MPa. Custom configurations are available for specific material requirements and production needs, ensuring optimal performance for your particular application.

The longitudinal guide system ensures precise wire placement and consistent coil formation, while the dual line direction capability provides exceptional flexibility for different production layouts. These features enable 30% faster setup times, reduce wire tangling by 45%, and allow seamless integration into existing production lines. The system can adapt to both left-to-right and right-to-left workflow configurations.

The ergonomic front-side unloading design reduces operator movement by 60% and decreases coil handling time by approximately 40%. This layout allows for seamless integration with downstream processes and minimizes floor space requirements. Operators can safely remove completed coils while the machine continues winding operations, increasing overall equipment effectiveness by up to 25% compared to traditional side-loading systems.

Standard models achieve production rates of 120-180 coils per hour depending on wire diameter and coil specifications. Cycle times range from 20-35 seconds per coil, with high-speed options available for volume production. The system maintains consistent tension control and winding precision throughout continuous operation, ensuring uniform coil quality and reliable performance in 24/7 manufacturing environments.

Our automatic coilers require minimal maintenance with daily visual checks (5 minutes) and weekly lubrication (30 minutes). We provide comprehensive training, detailed maintenance manuals, and 24/7 technical support. Remote diagnostics capability allows our engineers to troubleshoot issues quickly, reducing downtime by up to 70%. Service contracts include preventive maintenance, spare parts packages, and software updates to ensure optimal long-term performance.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts