Coil wrapper FPH-400

Project Information

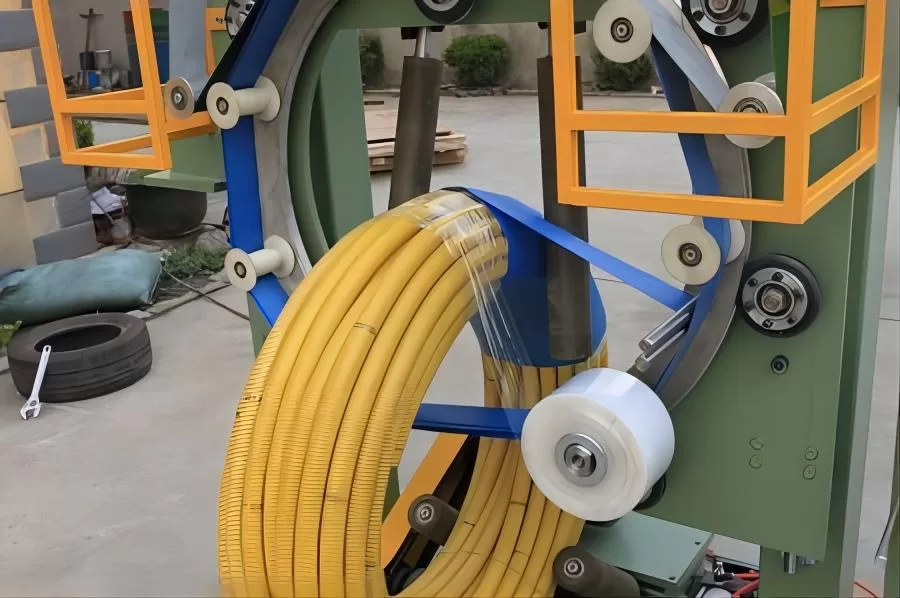

The FPH series coil wrapper is a versatile and efficient machine designed for wrapping small and light coils, such as hose coils, PEX pipes, and plastic pipes. With its vertical design and advanced features, it offers ease of operation, reliable performance, and significant cost savings.

Advantages

Cost Savings:

Reduces labor and material costs through automation and efficient operation.

Enhanced Product Protection:

Reliable wrapping prevents contamination and ensures durability during transit.

Ease of Use:

User-friendly design and adjustable settings allow seamless operation for varied requirements.

Automate small-coil wrapping with Wuxi BuHui’s FPH-400 Coil Spiral Wrapper. Vertical spiral design wraps each coil in 15–35 seconds, cutting labor, film waste, and damage.

The Challenge

- Labor-Heavy Manual Wrapping: Multiple operators and ergonomic risk.

- Uneven Protection: Inconsistent tension and overlap allow contaminants in.

- Material Waste: Imprecise cuts and overlap boost film costs.

- Throughput Limits: Slow cycles hinder production flow.

- Size Variability: IDs 400–800 mm, ODs 500–1200 mm, widths 50–400 mm, weights 3–25 kg demand quick changeovers.

- Operator Simplicity: Nontechnical staff need intuitive controls and safety features.

- Media Flexibility: Support for LLDPE, PE, stretch film, PVC, paper, HDPE without extra setup.

Features & Benefits

| Feature | Benefit & ROI |

|---|---|

| Vertical Spiral Design | Saves floor space and delivers uniform 360° coverage on small/light coils. |

| 15–35 s Cycle Time | Clears end-of-line bottlenecks and boosts throughput. |

| Inverter-Controlled Speeds | Fine-tune ring (20–90 RPM) and roller speeds for tight, consistent wraps. |

| Adjustable Overlap (20–90 %) | Balance protection and film use to cut material costs. |

| Sensor Positioning | Accurate start/stop ensures perfect alignments, reducing rework. |

| Soft Start/Stop & Guides | Protects machine and coil finish, enhancing safety and longevity. |

| Manual/Auto Modes & Alarms | Simplifies operation; instant alerts minimize downtime. |

| PU-Covered Surfaces | Prevents abrasion to preserve coil quality. |

| Media Flexibility & Auto Cut-Off | Supports multiple films and sheets; clean cuts reduce waste. |

| Quick Changeover | Handles ID 400–800 mm, OD 500–1200 mm, width 50–400 mm with minimal setup. |

| Robust, Low-Maintenance Build | Durable components and easy access cut service frequency. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | FPH-400 Coil Spiral Wrapper |

| Coil ID | 400–800 mm |

| Coil OD | 500–1200 mm |

| Width | 50–400 mm |

| Weight | 3–25 kg |

| Cycle Time | 15–35 s/coil |

| Ring Speed | 20–90 RPM (inverter) |

| Roller Speed | 2–4 m/min (inverter) |

| Overlap | 20–90 % |

| Power | 380 V/50 Hz, 1.8 kW |

| Control | Manual/automatic, sensor positioning, alarms |

| Safety | Soft start/stop, guide rollers, PU surfaces |

| Media | LLDPE, PE, stretch film, PVC, paper, HDPE |

| Maintenance | Easy-access sensors and inverters |

| Customization | Adaptable to coil specs and layout |

Ideal Applications & Industries

- Hose & Pipe Makers: Fast, consistent wrapping of light coils.

- Plastic & Piping OEMs: Protect coiled tubing from contamination.

- Packaging Contractors: High-speed spiral service for varied sizes.

- Warehousing & Logistics: Secure loads, reduce damage claims.

- Maintenance Teams: Quick rewrapping with minimal training.

- System Integrators: Plug-and-play into end-of-line cells.

Why Wuxi BuHui?

Wuxi BuHui’s FPH-400 wraps small/light coils in 15–35 s with inverter precision and sensor alignment. It slashes labor and film costs, protects products, and fits any layout—making it the smart choice for efficient, damage-free packaging.

Request a Quote

Contact Wuxi BuHui with your coil specs to customize an FPH-400 solution that maximizes throughput, minimizes waste, and ensures reliable protection.

The FPH-400 coil wrapper is a high-performance machine designed for efficient and secure wrapping of coils. It provides excellent protection against dust, moisture, and damage during storage or transportation. Featuring advanced automation, it ensures consistent wrapping quality while improving productivity. Compact and versatile, it suits various industrial packaging requirements.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Hose Coil wrapper FPH-200

The FPH-200 hose coil wrapper is a compact and efficient machine designed for secure wrapping of hose coils. It provides

View Details