Automatic steel wire winder and strapping machine

Project Information

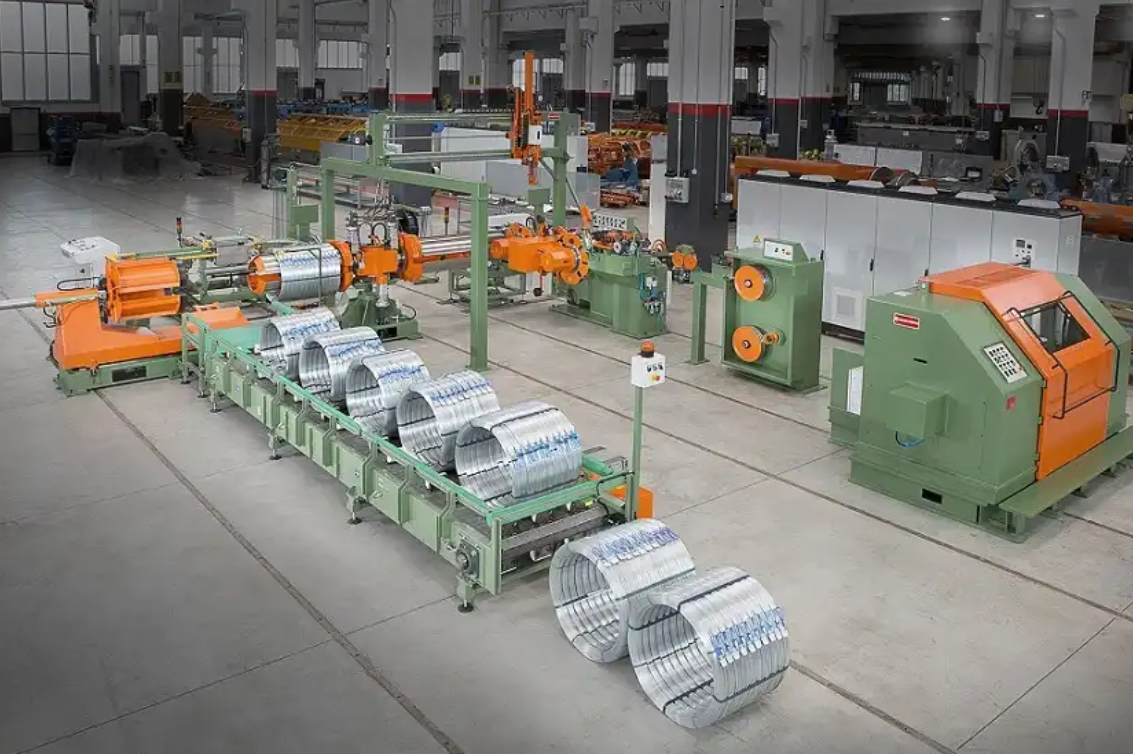

The Full-Automatic Wire Packaging Line is an innovative and efficient solution for the steel wire industry, meeting CE standards and utilizing advanced technology. Designed to address manpower shortages and reduce packaging costs, it automates the coiling, strapping, and stacking processes, ensuring high productivity and safety.

Key Components and Features

Vertical Tension Wire Accumulator

Adjusts wire tension with a DC-24V control cabinet.

Stores wire lengths between 5m–20m.

Equipped with safety features like emergency stop and limit switches.

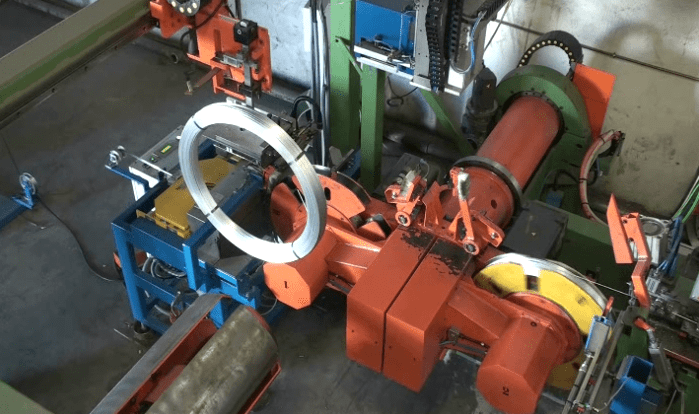

Automatic Coiling Machine

PLC-controlled for automatic feeding, coiling, and cutting.

Dual winding heads ensure non-stop operation.

Servo motor and HMI touch screen for precision and ease of use.

Advanced Full-Automatic Wire Packaging Line: Comprehensive Solution for the Steel Wire Industry

The Full-Automatic Wire Packaging Line is designed with cutting-edge technology to meet CE standards, making it a highly efficient and advanced solution for the steel wire industry. Developed by FHOPE, this system addresses critical challenges such as manpower shortages and packaging costs while significantly improving operational efficiency and productivity.

The FHOPE Group provides end-to-end support, including sales, design, quality assurance, and after-sales services, ensuring tailored solutions to meet the unique requirements of each customer.

Core Components and Features

A. Vertical Tension Wire Accumulator

Key Features:

Designed to store wire in a vertical orientation with adjustable tension control.

Assembled with steel plates for robust durability.

Operated via a DC-24V control cabinet for precise adjustments.

Handles a cumulative wire length of 5m-20m, suitable for diverse production needs.

Equipped with a deceleration motor to avoid over-tensioning and wire breakage.

Safety Enhancements:

Includes multiple limit switches for emergency stopping if a wire breaks, ensuring operational safety.

Benefits:

Enhances efficiency by securely storing wire and maintaining tension.

Reduces risks of wire damage during storage and processing.

B. Automatic Coiling Machine

Key Features:

Controlled by a Programmable Logic Controller (PLC) to store wire specifications for quick and efficient setup.

Includes a double winding head for continuous operation, minimizing downtime.

Automatically performs wire feeding, winding, and cutting, reducing manual input.

Advanced Controls:

Features an HMI touch screen for intuitive operation, with speed control and an emergency stop button.

Utilizes a servo motor for precise transverse movement and coil shaping.

Safety and Accuracy:

Integrated automatic alarm system alerts operators to abnormalities during operation.

Equipped with a length meter counter featuring aluminum alloy wheels and ceramic-treated PU wheels for durability and accuracy.

Benefits:

Increases productivity with seamless automation.

Ensures uniform and precise coiling, reducing material waste and errors.

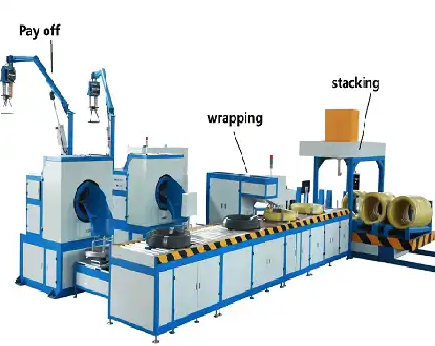

C. Automatic Coil Strapping Machine

Key Features:

Automatically applies PP belts to securely strap wire coils.

Adjusts tension automatically for consistent strapping.

Features hot welding for durable seals at the strapping positions.

Straps coils at multiple positions (3-6) to enhance stability during transport.

Automation and Customization:

Controlled by a PLC program, reducing the need for manual adjustments.

Adjustable tension accommodates varying coil sizes.

Ease of Use:

Belt distributor and accumulator are fixed in position for easy operation.

Benefits:

Increases safety and reliability during storage and transportation.

Saves labor costs and boosts operational efficiency.

D. Automatic Wire Coil Unloading Machine

Key Features:

Automatically transfers coils from the strapping position to the unloading area.

Operated via automatic program control for smooth and precise movements.

Technology Integration:

Equipped with a crane and guide rail system to facilitate stacking and unloading.

Benefits:

Completes the final step of the packaging process efficiently.

Reduces manual labor and ensures secure handling of finished coils

Advantages of the Full-Automatic Wire Packaging Line

Enhanced Efficiency:

Automates the entire process, from coiling to stacking, significantly reducing downtime and manual errors.

Improved Accuracy:

Ensures precise tension control, coiling, and strapping, resulting in consistent and high-quality output.

Cost-Effectiveness:

Reduces labor dependency and minimizes material waste, optimizing overall costs.

Safety and Reliability:

Built with robust safety features, including limit switches, emergency stops, and alarms.

Incorporates high-quality components from well-known brands for durability and long-term performance.

Customizable Solutions:

Offers options like weighing systems, labeling machines, and adjustable strapping configurations to meet specific requirements.

Technical Data

| Specification | Details |

|---|---|

| Strap Width | 10mm |

| Strap Thickness | 0.8 mm |

| Type of Strap | PP Belt |

| Strap Quality | Smooth / High-quality polyester strap |

| Type of Joint | By friction - vibration |

| Joint Location | The strapping is performed in the front part of the wire coil. |

| Joint Efficiency | Approx. 75-90% of the breaking load of the strap. |

Applications in the Steel Wire Industry

The Full-Automatic Wire Packaging Line is ideal for:

Steel Wire Manufacturing Plants

Cable Production Facilities

Metal Coil Processing Centers

Industrial Packaging Operations

Why Choose FHOPE’s Packaging Line?

Comprehensive Support: From initial consultation to after-sales services, FHOPE ensures seamless integration into your operations.

Advanced Automation: Incorporates state-of-the-art technology for unmatched performance.

Safety and Compliance: Designed to meet CE standards, ensuring safe and reliable operations.

Tailored Solutions: Customizable features to suit unique production needs.

By investing in the Full-Automatic Wire Packaging Line, businesses can streamline their packaging processes, improve productivity, and maintain high standards of product quality while minimizing operational costs. This packaging line is a testament to FHOPE's commitment to innovation and excellence in the steel wire industry.

An automatic steel wire winder and strapping machine is an advanced industrial tool designed to coil steel wires and securely strap them for storage or transportation. It automates the process, ensuring precision, consistency, and reduced labor costs. Ideal for steel manufacturing, it enhances productivity and maintains product quality.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Automatic wire coiler

An automatic wire coiler is a specialized machine that automates the coiling, cutting, and packaging of wires. It enhance

View DetailsAutomatic steel wire winder and

The automatic steel wire winder and strapping machine is an innovative solution for coiling and strapping steel wire coil

View DetailsSteel wire winding and wrapping

A steel wire winding and wrapping machine is a specialized industrial equipment designed to coil and securely wrap steel

View DetailsAutomatic steel wire winding an

An automatic steel wire winding and binding machine is a high-performance equipment designed to coil and bind steel wires

View DetailsAutomatic steel wire winder and

An automatic steel wire winder and packing line is an advanced system designed to streamline the coiling and packaging of

View Details