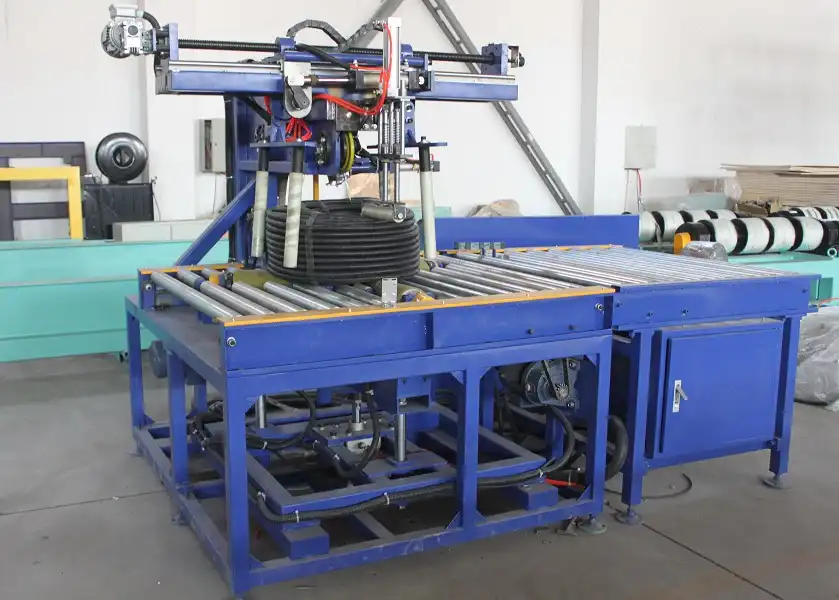

Bearing packing machine FPB-400

Project Information

The bearing wrapping machine is a highly automated and flexible solution tailored for efficiently packaging large bearings. It is ideal for industries such as automotive, aerospace, and manufacturing, where precision and consistency are critical.

Key Features

Seamless infeed/outfeed conveyors cut manual handling and accelerate throughput

PLC stores six programs for instant changeovers via simple keypad

Auto centralized positioning delivers pinpoint bearing alignment and uniform packaging

Compatible with diverse packing materials to suit any product need

Manual or semi-auto wrapping of large bearings and axletrees demands heavy labor, risks uneven protection, and drives up waste. Wuxi BuHui’s FPB-400 Bearing Wrapping Machine automates positioning, tensioning, and wrapping—so one operator maintains consistent, high-quality packaging.

The Challenge: Packaging Large Bearings Efficiently

- Intensive Manual Handling: Heavy bearings require multiple operators and create ergonomic risks.

- Uneven Wraps: Lack of precise centering and tension control leads to loose or over-tight wraps.

- Excess Material Waste: Inaccurate overlap and cut-off cause unnecessary film or paper use.

- Flow Disruptions: Manual transfer between production and packaging stalls lines.

- Slow Changeovers: Varying bearing sizes demand lengthy manual adjustments.

- Extended Downtime: No auto fault detection delays maintenance response.

- Safety Hazards: Handling heavy parts without reliable conveyors and guards risks accidents.

The Solution: Features & Benefits

| Feature | Benefit & ROI |

|---|---|

| PLC with Six Stored Programs | Recall packaging recipes instantly—cuts changeover time and ensures repeatable results. |

| Automatic Centralized Positioning | Centers each bearing for uniform wraps—eliminates manual alignment errors. |

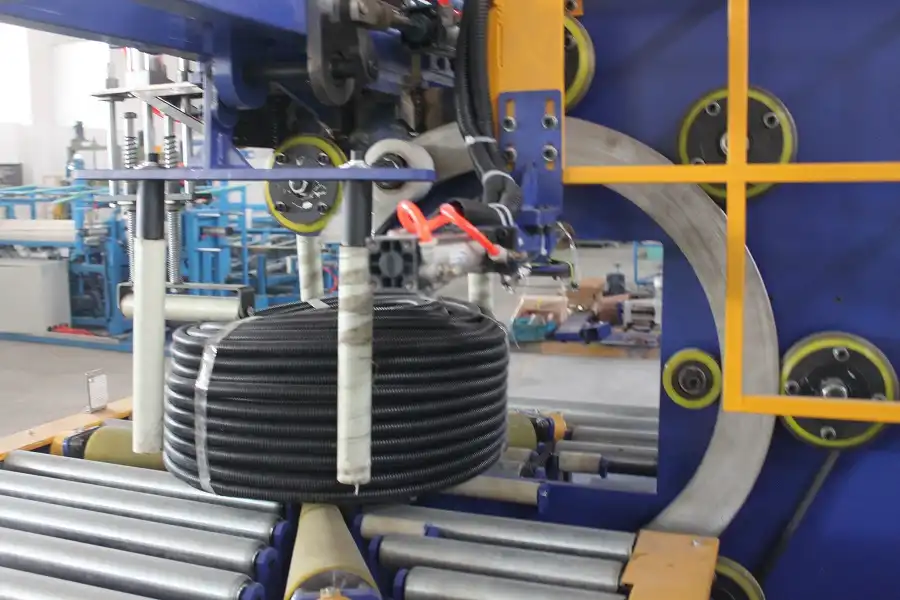

| Infeed & Outfeed Conveyors | Handles heavy loads automatically—reduces manual lifting and speeds throughput. |

| Adjustable Tension & Overlap | Tune wrap tightness (20–90%) to secure protection while cutting material costs. |

| Material Flexibility | Supports film, paper, woven/knit belts, PVC, and more—match protection to your budget. |

| Heavy-Duty Construction | Handles 100–500 kg bearings reliably—minimizes maintenance and maximizes uptime. |

| User-Friendly Interface | Keypad/touchscreen input for ID/OD/width—simplifies setup and reduces training. |

| Variable Speed Control | Adjust ring speed (30–70 RPM) to balance throughput (30–50 sec/piece) and wrap quality. |

| Automatic Cut-Off System | Clean, precise cuts after each wrap—prevents waste and cleanup delays. |

| Line Integration | Syncs with upstream conveyors—streamlines flow and avoids bottlenecks. |

| Real-Time Fault Alerts | Detects jams or misfeeds instantly—minimizes downtime with immediate alerts. |

| Safety Guards & Emergency Stop | Protects operators during handling of heavy parts—meets CE standards. |

| Easy Maintenance Access | Quick-open panels for conveyors, cutters, and sensors—reduces service time. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Model | FPB-400 Bearing Wrapping Machine |

| Bearing ID Range | 300–800 mm |

| Bearing OD Range | 500–1200 mm |

| Bearing Width | 100–400 mm |

| Bearing Weight | 100–500 kg |

| Power Supply | AC 380 V, 50 Hz, 3-phase |

| Power Consumption | 2.5 kW |

| Wrapping Speed | 30–50 sec/piece |

| Ring Speed | 30–70 RPM |

| Overlap Rate | 20%–90% |

| Packing Materials | Film, paper, woven/knit belt, PVC, goffered paper |

| Program Storage | Up to 6 recipes |

| Conveyors | Infeed & outfeed with speed control |

| Tension Control | Adjustable via con |

The FPB-400 bearing packing machine offers a streamlined solution for secure and efficient bearing packaging. Designed for durability and ease of use, it provides consistent wrapping to protect bearings from contamination and damage. Its automated features improve workflow efficiency, making it suitable for various industrial applications and packaging standards.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Bearing packing machine

A bearing packing machine streamlines the packaging of bearings by utilizing automated systems for accuracy and speed. It

View DetailsBearing wrapping machine

The bearing wrapping machine is designed to provide efficient and protective packaging for bearings. It ensures a secure

View DetailsBearing packing line

The bearing packing line is a comprehensive solution for efficient and reliable bearing packaging. It automates processes

View DetailsBig size bearing packing machin

The big-size bearing packing machine is a specialized solution for packaging large bearings with precision and care. It o

View DetailsBearing bag packing machine

The bearing bag packing machine provides an efficient solution for sealing bearings in protective bags. It ensures secure

View Details