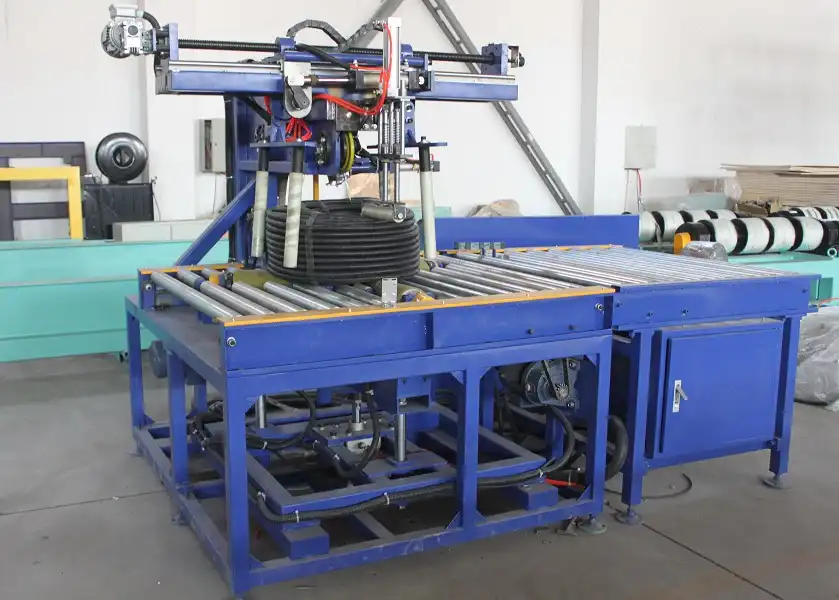

Tyre packing machine

Project Information

A high-quality tyre packing line integrates advanced features and automation to provide a fast, accurate, and efficient solution for packaging tyres into pallets, preparing them for transportation and storage. With a focus on flexibility, safety, and durability, this system is well-suited for diverse industrial applications.

Key Features of the Tyre Packing Line:

CE-certified premium electrical components for reliable, safe performance

PLC & touchscreen interface enabling intuitive, seamless control

Integrated infeed conveyor and stacker for fully automated workflow

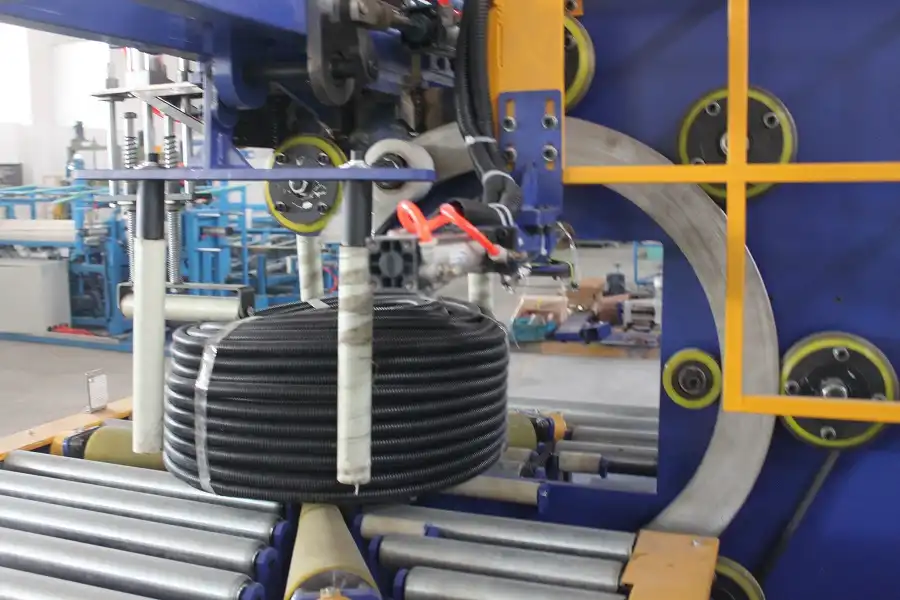

Inverter-driven ring, roller, and conveyor speeds for pinpoint wrapping precision

Transform Your Tire Packaging with Wuxi BuHui

Traditional tire packaging uses separate wrapping, taping, labeling, and palletizing stations with manual hand-offs. This fragmented approach drives up labor costs, creates quality inconsistencies, and keeps your data trapped in silos. Wuxi BuHui’s Automatic Tire Packaging Line unifies horizontal wrapping, tape application, online labeling, and robotic palletizing into one PLC-controlled workflow—boosting throughput, safety, and traceability.

The Challenge: Streamlining Disconnected, Labor-Intensive Packaging

- Multiple Machines & Manual Steps: Hand-offs between wrapping, taping, labeling, and palletizing add cycle time and human error.

- Variable Wrap & Tape Quality: Lack of integrated tension control and precise tape feeds leads to uneven overlaps and weak adhesion.

- Data Silos: No link between packaging stages and your production systems makes traceability and reporting difficult.

- Space & Size Constraints: Different tire IDs (150–500 mm), ODs (600–1000 mm), and factory layouts demand a custom approach.

- High Labor Costs & Safety Risks: Manual transfers increase headcount and expose operators to pinch points and lifting injuries.

- Complex Maintenance: Disparate controls and unclear alarms slow troubleshooting and cause unplanned downtime.

- Scalability Limits: Growing volumes stall when your line relies on disconnected equipment and hand-offs.

The Solution: Integrated Line Features & ROI

Wuxi BuHui’s line brings horizontal wrapping, automatic “tapping,” online labeling, and robotic palletizing under a single PLC/HMI platform—eliminating hand-offs and delivering consistent, data-driven packaging.

| Feature | Benefit / ROI |

|---|---|

| Integrated PLC-Controlled Horizontal Tire Wrapping | Maintains precise tension (20–90%) and overlap for IDs 150–500 mm & ODs 600–1000 mm, eliminating manual tweaks and rewraps. |

| Automatic Tape Application (“Tapping” Device) | Feeds, cuts, and applies BOPP or specialty tapes to exact positions—improving seal integrity and reducing material waste. |

| Online Printing & Labeling Module | Pulls production data, prints and applies labels in one move—ensuring full traceability and brand compliance. |

| Robotic Palletizer | Clamps, lifts, and stacks tires up to 1200 mm high—cutting labor by up to 80% and reducing injury risk. |

| Modular, Customizable Layout | Adapts conveyors, wrappers, and palletizers to fit any facility footprint and future capacity increases. |

| Sensor & PLC Feedback | Displays clear error codes on HMI for fast troubleshooting and less unplanned downtime. |

| Inverter-Adjustable Speeds | Optimizes wrapping (30–35 sec/tyre), conveyor flow, and palletizer rhythm to match any production rate. |

| PU-Covered Support Rollers | Centers and protects tires during wrap—preventing surface marks and wobble. |

| Soft Start/Stop & Auto Reset | Smooth machine moves protect equipment and tires; auto ring positioning ensures consistent cycle starts. |

| CE-Compliant Components | Built with Siemens PLCs, Schneider contactors, and robust frames for reliable, low-maintenance operation. |

| Data Integration & Exchange | Seamlessly syncs with MES/ERP systems—enabling real-time reporting and full end-to-end traceability. |

| Flexible Material Support | Handles stretch film, BOPP tapes, and more with adjustable tension and feed settings. |

| Auto Length Calculation & Material Change | Automatically measures and swaps wrap or tape rolls—saving setup time and reducing waste. |

| Safety Guardrails & Covers | Shields operators from moving parts—enhancing workplace safety and compliance. |

Technical Specifications

| Specification | Details |

|---|---|

| Tire Dimensions | ID: 150–500 mm; OD: 600–1000 mm; Height: 150–300 mm; Weight: 5–100 kg |

| Wrapping Speed | Approx. 30–35 seconds per tire |

| Overlap Rate | Adjustable 20–90% |

| Wrap Material | Stretch film; roll ID 50 mm, OD 80–120 mm, Width 60–70 mm |

| Tape Application | Automatic BOPP feed and cut; height-adjustable |

A tyre packing machine is an innovative solution for wrapping and securing tyres efficiently. It provides protective packaging using stretch film or similar materials, safeguarding tyres from damage during transport or storage. With automated features, it improves packaging speed, consistency, and reduces operational costs, making it ideal for industrial applications.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Tyre Packing Machine FPT-100

The FPT-100 Tyre Packing Machine provides efficient, reliable tire packaging for safe transport and storage. With a compa

View DetailsTyre Packing Machine FPT-200

The Tyre Packing Machine FPT-200 is a high-efficiency solution designed to streamline tire packaging processes. It offers

View DetailsTyre Packing Machine FPT-300

The FPT-300 Tyre Packing Machine is designed for efficient, high-speed wrapping of tires, enhancing packaging protection

View DetailsHorizontal Tyre Stretch Wrapper

A tyre wrapper is an advanced packaging machine designed to wrap tyres with stretch film or other protective materials ef

View Details