Horizontal Tyre Stretch Wrapper

Project Information

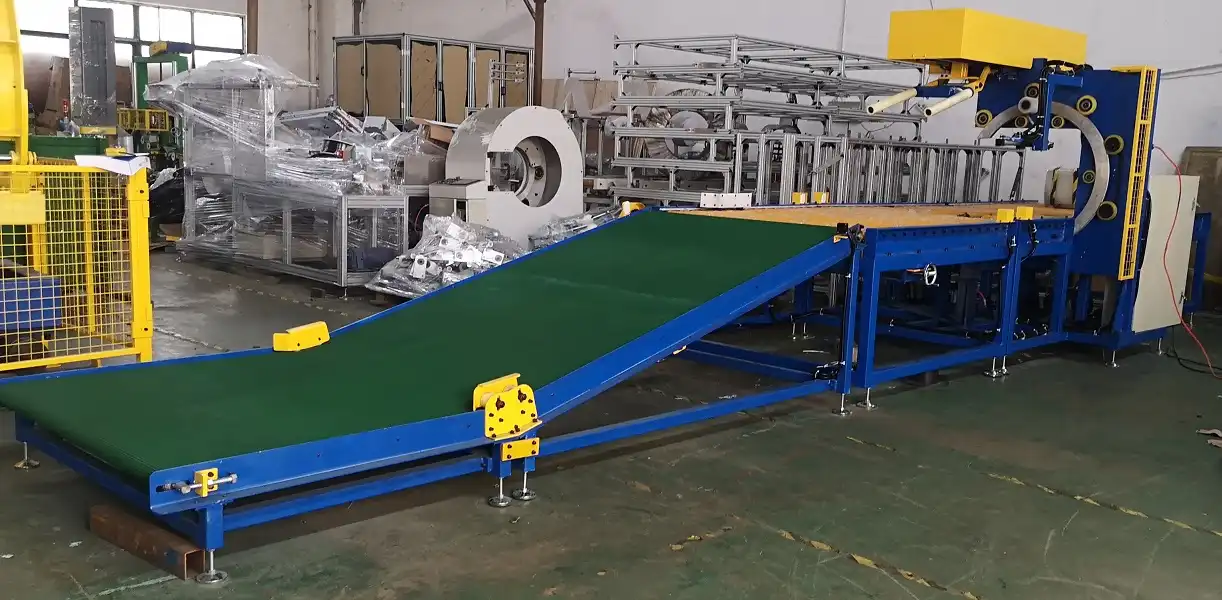

The horizontal tyre stretch wrapper is designed for efficiently wrapping tyres in film, providing a streamlined solution for industries like manufacturing, distribution, and logistics. Its automation and adaptability make it an essential tool for high-volume operations.

Benefits:

Automates wrapping steps to boost throughput.

Delivers uniform wraps for optimal protection and presentation.

Adapts to diverse tire sizes and shapes.

Integrates seamlessly with spool pickers and buffer conveyors.

Challenge: Inefficient Tyre Packaging

- Low throughput & high labor: Multiple operators and stops slow your line.

- Uneven wrap quality: Manual tensioning leads to inconsistent protection and appearance.

- Lengthy changeovers: Adjusting for different tyre sizes adds downtime.

- Fragmented workflow: Separate loading, wrapping, unloading steps interrupt continuity.

- Material waste: Manual cutting causes excess film scrap and longer cycles.

- Safety risks: Unstable tyres during wrap can shift or tip.

- Complex commissioning: Disparate equipment requires lengthy setup and troubleshooting.

Solution Highlights: Automatic Horizontal Tyre Stretch Wrapper

Fully integrated online system with conveyor feeding, auto film feed & cut, and 360° ring positioning—delivering uniform, high-speed wrapping in 25–35 seconds per tyre.

| Feature | Benefit / ROI |

|---|---|

| Auto Roller Conveyor Feeding | Continuous tyre flow cuts manual handling and boosts throughput. |

| Automatic Film Feeding & Cutting | Exact material lengths slash film waste and setup time. |

| 360° OD Positioning & Full-Side Wrap | Auto-centering and ring rotation guarantee uniform coverage. |

| PLC Control with HMI | One-screen operation simplifies adjustments and diagnostics. |

| Inverter-Adjustable Speeds | Tune roller & ring rates for perfect tension on any tyre size. |

| Adjustable Tension Control | Consistent film tension prevents loose or overstretched wraps. |

| Wide Material Compatibility | Works with stretch film, paper, PE, foil—for branding or protection. |

| Quick Size Adaptation | Minimal mechanical adjustments for fast changeovers. |

| Soft Start/Stop & Auto Reset | Smooth motion protects tyres; auto reset readies next cycle. |

| Sensor Fault Detection & Alarms | Instant alerts on HMI reduce downtime and troubleshooting. |

| Robust Safety Guards | Guardrails and covers keep operators clear of moving parts. |

| Compact Inline Design | Fits after spoolers or conveyors—small footprint, big impact. |

| High Throughput (25–35 sec/tyre) | Meets tight production targets and drives down labor cost. |

Technical Specifications

| Specification | Details |

|---|---|

| Machine Type | Automatic Horizontal Tyre Stretch Wrapper |

| Tyre Size Range | ID 300–900 mm, OD 600–1400 mm, Height 150–350 mm, Weight 10–100 kg |

| Wrapping Speed | 25–35 seconds per tyre |

| Conveyor Speed | 2–4 m/min |

| Ring Speed | 10–120 rpm (inverter) |

| Film Handling | Auto measure & cut; supports ID 50 mm, OD 80–120 mm, Width 90–120 mm |

| Materials Supported | Stretch film, paper, PE film, foil (ID 50 mm, OD 100–450 mm, Width 90–120 mm) |

| Control System | PLC + Touchscreen HMI |

| Power | 380 V/50 Hz/3-phase, ~4.0 kW |

| Air Supply | 5–7 bar |

| Construction | Heavy-duty frame, PU rollers, safety guards |

| Customization | Layout, tyre ranges, material types to suit your line |

Ideal Applications & Industries

- Tyre Manufacturers: Inline bundling for seamless shipping prep.

- Distributors & Warehouses: Consistent protection at high speed.

- OEM & Aftermarket: Integrated packaging with production lines.

- Logistics & Fulfillment: Streamlined flow to palletizing.

- Retail & Service Centers: Quick bundling for shop floor efficiency.

- Plant Upgrades: Custom layouts fit existing conveyors/spoolers.

Why Wuxi BuHui?

Wuxi BuHui’s Horizontal Tyre Stretch Wrapper unites conveyor feeding, auto film feed & cut, and 360° positioning. With PLC/HMI control, inverter speeds, and full-side wraps in under 35 seconds, it slashes labor, reduces waste, and delivers uniform, safe packaging. Robust safety features and compact inline design make integration simple. Quick adjustments and clear alarms keep uptime high. Elevate your tyre line with Wuxi BuHui’s proven efficiency and reliability.

Request a Quote

Ready to transform your tyre packaging? Contact our team today to discuss customization and get your quote.

A tyre wrapper is an advanced packaging machine designed to wrap tyres with stretch film or other protective materials efficiently. It ensures secure, consistent packaging to prevent damage during transport or storage. Ideal for industrial applications, it enhances productivity, reduces manual labor, and delivers high-quality, cost-effective packaging solutions.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Tyre Packing Machine FPT-100

The FPT-100 Tyre Packing Machine provides efficient, reliable tire packaging for safe transport and storage. With a compa

View DetailsTyre Packing Machine FPT-200

The Tyre Packing Machine FPT-200 is a high-efficiency solution designed to streamline tire packaging processes. It offers

View DetailsTyre Packing Machine FPT-300

The FPT-300 Tyre Packing Machine is designed for efficient, high-speed wrapping of tires, enhancing packaging protection

View DetailsTyre packing machine

A tyre packing machine is an innovative solution for wrapping and securing tyres efficiently. It provides protective pack

View Details