Tired of Inefficient Manual Hose & Pipe Coiling?

Discover how Fhope's fully automatic coiling and strapping systems eliminate production bottlenecks while delivering perfectly consistent coils every time.

Labor-Intensive Coiling Processes

Manual winding of industrial hoses and pipes consumes excessive time and increases labor costs significantly.

Inconsistent Coil Quality

Variable tension in manual operations creates irregular coils that complicate storage and transportation.

Insufficient Strapping Security

Hand-applied straps frequently loosen during transit, leading to uncoiled products and customer complaints.

Limited Production Scalability

Manual methods cannot keep pace with growing order volumes, restricting business expansion capabilities.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

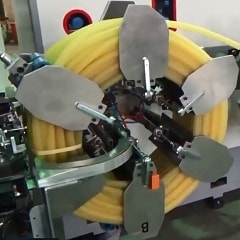

Vertical Automatic Coiler Manufacturing Excellence

A Vertical Automatic Coiler is a specialized machine designed for efficiently coiling materials like wires, cables, or hoses into precise, compact rolls. Ideal for industrial applications, it automates the coiling process, enhancing speed, accuracy, and productivity. With customizable settings, it ensures consistent coil dimensions while minimizing labor efforts. Perfect for streamlining packaging

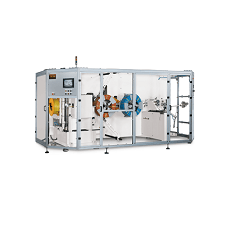

Horizontal Automatic Coiler

The Horizontal Automatic Coiler is an innovative machine designed for efficient wire coiling and packaging. With precise tension control, high-speed automation, and customizable settings, it ensures consistent coil formation and secure bundling. Ideal for industrial applications, it enhances productivity, reduces labor dependency, and delivers reliable, high-quality results for wire management.

Vertical Automatic Coiler

A Vertical Automatic Coiler is a specialized machine designed for efficiently coiling materials like wires, cables, or hoses into precise, compact rolls. Ideal for industrial applications, it automates the coiling process, enhancing speed, accuracy, and productivity. With customizable settings, it ensures consistent coil dimensions while minimizing labor efforts. Perfect for streamlining packaging

Precision Vertical Automatic Coiling Systems

Fhope's vertical automatic coilers revolutionize pipe and hose packaging with intelligent automation, delivering perfectly wound coils ready for secure transport and storage. Our engineered solutions eliminate manual coiling inconsistencies while maximizing production throughput.

Automated Coiling & Strapping: Integrated system handles complete winding and securing process in single operation, eliminating manual handling.

Adaptive Size Configuration: Handles various pipe diameters (10-150mm) and hose types with quick-change tooling and programmable settings.

Intuitive Operation Interface: Simplified controls with touchscreen programming require minimal operator training for immediate productivity.

Labor Reduction

Faster Coiling Speed

Operation Reliability

Coils Per Shift

Automotive Hose Manufacturer Achieves 300% ROI with Automated Coiling

Production Challenge

A leading automotive components supplier struggled with manual hose coiling operations, experiencing inconsistent coil tightness, high labor turnover, and inability to meet growing production demands for their cooling and fuel line systems.

Fhope Automation Solution

We implemented a customized vertical automatic coiling and strapping system that automatically processes multiple hose types with precision tension control. The results: production output increased from 80 to 300 coils per shift, packaging consistency improved by 95%, and the system paid for itself in under 8 months of operation.

Request Your Custom Coiling Solution

SHOWCASE & NEWS

Vertical Automatic Coiler FAQ

Frequently Asked Questions About Automated Pipe and Hose Coiling Systems

A vertical automatic coiler is a specialized machinery solution that automates the winding and coiling process for pipes, hoses, and flexible tubing. This advanced equipment precisely winds materials into uniform, compact coils while integrating strapping mechanisms for secure bundling. By eliminating manual handling, our coiling systems increase output by up to 300% while ensuring consistent coil quality and reducing product damage during packaging operations.

Our vertical coilers are engineered to process diverse flexible materials including PVC pipes, polyethylene tubing, rubber hoses, irrigation pipes, and electrical conduits. The systems accommodate diameters from 6mm to 50mm and can create coils with outer diameters ranging from 300mm to 1200mm. Customizable tension control ensures optimal winding for different material flexibility and surface characteristics without deformation or surface damage.

Automated coiling systems deliver substantial advantages over manual operations: 75% reduction in labor requirements, consistent coil tightness and diameter, integrated automatic strapping, and production speeds of 15-30 coils per hour. These systems also minimize repetitive strain injuries and can operate continuously with minimal supervision. Most facilities achieve ROI within 8-18 months through labor savings and increased throughput.

Yes, our vertical automatic coilers feature modular designs that enable seamless integration with extrusion lines, cutting machines, and downstream packaging equipment. We provide custom interface solutions including conveyor connections, PLC synchronization, and data exchange capabilities. Our engineering team conducts comprehensive site assessments to ensure smooth integration with your current manufacturing layout and production workflow.

Maintenance requirements are minimal and scheduled for maximum uptime. Daily tasks include visual inspection and cleaning (10 minutes). Weekly maintenance involves checking tension settings and lubrication points (30 minutes). Monthly procedures include belt tension verification and component wear assessment (2 hours). We provide comprehensive maintenance training, detailed manuals, and remote diagnostic support to minimize operational disruptions.

Absolutely. Fhope specializes in custom coiling solutions tailored to unique product specifications and production environments. We've developed specialized systems for small-diameter film coils, custom strapping patterns, integrated labeling, and automated palletizing. Our engineering team works directly with clients to design machinery that addresses specific challenges in coil configuration, packaging materials, and production volume requirements.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts