Coil packing | Coil Wrapping Solution

Project Information

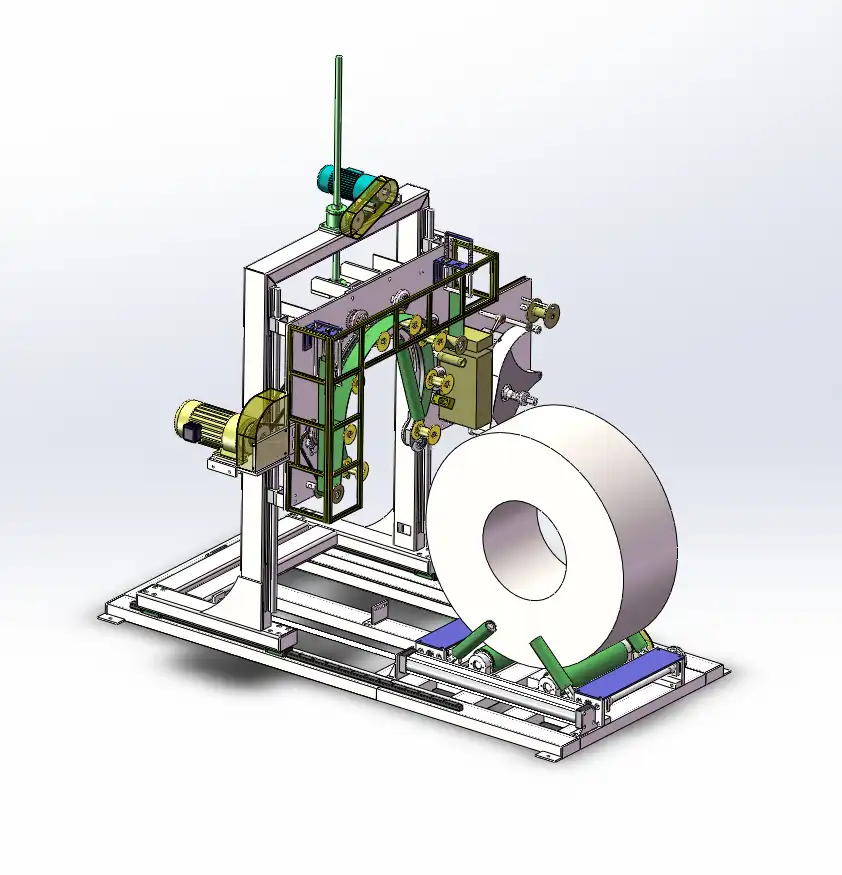

This highly efficient and versatile coil wrapping machine is designed to provide precise, safe, and cost-effective solutions for various coil packaging needs. Equipped with advanced features, it ensures consistent wrapping quality and easy operation for diverse applications.

Key Features:

Auto-Return: Easy load/unload

Overlap Control: Inverter precision

Height Ring: Motor-adjustable

Tension: Secure wrap

The Challenge: Unsafe, Inconsistent Manual Wrapping

- Safety Risks: Operators exposed during setup and crane loading.

- Quality Variability: Manual tensioning leads to loose wraps or over-tightening.

- Downtime & Waste: Frequent adjustments and re-wraps slow production and increase material use.

The Solution: Automated, PLC-Driven Dual-Layer Wrapping

- Vertically Movable Station: Provides headroom for safe crane loading/unloading.

- Auto-Detect & Adjust: PLC reads coil OD and sets tension & overlap automatically.

- Paper + Film in One Pass: Combines layers in a single cycle for superior protection.

- Inverter-Controlled Speed & Overlap: Fine-tune wrap tightness and coverage to minimize waste.

- Motorized Support Rollers: Polyurethane-covered rollers protect coil surfaces and adapt to varied profiles.

- Integrated Cutter & Carriage: Automates film feed and cut—eliminating manual steps.

- Safety Features: Guardrails, soft start/stop and position reset prevent abrupt movements.

- Rugged Design: Operates reliably in 5–45 °C, 20–99% RH, dusty environments.

Features & ROI

| Feature | Benefit / ROI |

|---|---|

| Vertically Movable Wrapping Station | Safe crane loading/unloading; faster cycle times; reduced injury risk. |

| PLC-Controlled Automation | Consistent tension & overlap; fewer errors; less rework. |

| Dual-Layer Wrapping (Paper + Film) | Enhanced dust/moisture protection; one-pass efficiency. |

| Inverter-Controlled Speed & Overlap | Optimized material use; secure, uniform wraps. |

| Polyurethane Support Rollers | Protects coil finish; adapts to varying profiles. |

| Automatic Cutter & Carriage | Reduces manual steps; shortens cycle time. |

| Safety Guards & Soft Start/Stop | Prevents abrupt movements; minimizes downtime. |

| Robust Build for Harsh Sites | Reliable uptime in extreme conditions. |

Technical Specifications

| Component | Specification |

|---|---|

| Coil Weight | 80–1,000 kg |

| Coil Width | 100–500 mm |

| Coil OD | 750–1,500 mm |

| Coil ID | 490–610 mm |

| Wrap Time | 40–65 s (depending on size) |

| Roller Speed | 2–4 m/min |

| Rotation Speed | 10–90 r/min |

| Overlap | 10%–90% |

| Power | 3 kW; 380 V/50 Hz, 3-phase |

| Air Supply | 5–8 bar |

| Footprint | 1,600×1,800×2,000 mm |

| Packing Materials | Paper/HDPE belt: 100–120 mm W, OD 100–450 mm, ID 76 mm, >85 gsm Stretch/PVC film: 100–120 mm W, OD 100–200 mm, ID 76 mm, >23 μm |

| Site Conditions | 5–45 °C; 20–99% RH; dusty atmosphere |

Request a Quote

Ready to upgrade your coil packaging? Contact Wuxi BuHui today for a customized solution that enhances safety, quality and efficiency.

Coil packing and wrapping solutions are designed to securely package steel, wire, and aluminum coils for safe transport and storage. These systems offer enhanced protection against environmental factors, reduce damage risks, and streamline operations, ensuring efficient, cost-effective, and high-quality packaging for industrial and manufacturing needs.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Wire coil wrapping machine FPW-

The FPW-800 wire coil wrapping machine is designed for efficiently packing wire coils with the assistance of a trolley fo

View DetailsWire coil wrapping machin FPW-6

FPW-600 series wire coil wrapping machine seems like a great investment for companies that need to package pc wire and pr

View DetailsWire coil wrapping machine FPW-

FPW-500 takes use of Siemens PLC as the control system for the machine is a great choice as it is a well-respected brand

View DetailsWire coil wrapping machine FPW-

FPW series wire coil wrapping machine. It sounds like a useful and efficient piece of equipment for packaging steel wire

View DetailsWire coil wrapping machine FPW-

The FPW-300 wire coil wrapping machine is a versatile solution for packaging small to medium-sized wire coils. It ensures

View DetailsRazor Wire Wrapping Machine

A razor wire wrapping machine is a specialized solution for securely bundling and packaging razor wire rolls. It provides

View DetailsAutomatic Wire Coiler

An automatic steel wire machine automates the production, handling, and packaging of steel wires with high precision and

View DetailsAutomatic steel wire coil wrapp

An automatic steel wire coil wrapping machine provides a fast and reliable solution for securely wrapping steel wire coil

View Details