Small Horizontal Stretch Wrapper E100

Project Information

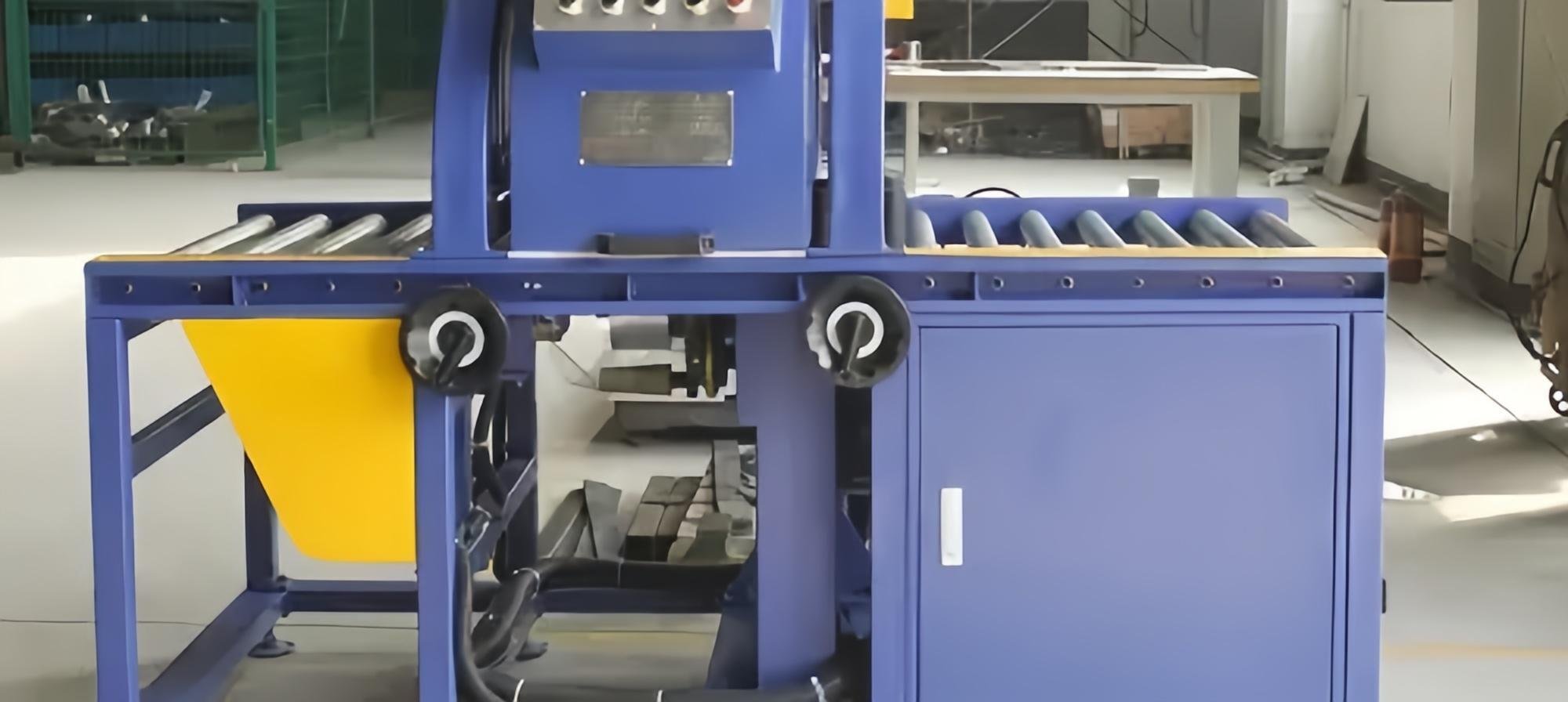

The FHOPE Fully Automatic Horizontal Wrapping Machine E100 is a cutting-edge packaging solution designed for exceptional performance, efficiency, and versatility. Ideal for automating production lines and reducing operating costs, it offers precise, reliable, and cost-effective packaging for various industries.

Core Features:

Fully automated PLC & sensor-driven operation

Fits pipes, doors, panels in logistics & manufacturing

Tight, uniform single- or double-layer wrap

Cuts labor & film waste, boosts product protection

E100 Small Horizontal Stretch Wrapper

Automate wrapping of small-diameter bundles (OD 50–100 mm, length > 1000 mm) with consistent tension, zero scratches, and minimal labor. Install on flat floors—no foundations needed—and tailor ring size, conveyor length, and pre-stretch options to your line.

Core Benefits

- Consistent Tension: Adjustable PU wheels ensure uniform wrap, cutting film waste.

- Surface Protection: Soft-surface conveyors and guide rails guard delicate profiles.

- Hands-Free Cycles: PLC-controlled feeding, clamping & cutting free up operators.

- Quick Install: Modular design mounts on any flat, hard floor—no civil work required.

- Flexible Configuration: Choose ring size, conveyor length, motor & pre-stretch frame to match your products.

Features & ROI

| Feature / Component | Benefit / ROI |

|---|---|

| Compact Cast-Aluminum Ring & Adjustable PU Wheels | Stable orbital rotation and precise tension control, slashing film waste. |

| PLC-Controlled Inverter-Driven Speeds | Match ring (20–120 r/min) and conveyor (6–12 m/min) speeds to bundle size and film type for faster cycles. |

| Tension & Overlap Control (10–90%) | Fine-tune film tension and overlap to secure even the smallest bundles. |

| Soft-Surface Conveyors & Guide Rails | Prevent scratches on aluminum, copper, and other delicate surfaces. |

| Automatic Feeding & Cutting | Unmanned film clamping and clean cuts accelerate throughput. |

| Photocell Positioning & PLC Program | Sensor-based start/stop avoids miswraps and line stoppages. |

| Soft Start & Auto Reset | Smooth ring engagement and instant reset extend equipment life. |

| EU Safety Guardrails & Alarms | Protect moving parts and alert on faults to keep operators safe. |

| Modular Flat-Ground Installation | Deploy on any hard floor (>1 ton/m²) without foundations—minimize civil costs. |

| Pre-Stretch Frame Option (100–250%) | Reduce film consumption and boost wrap consistency. |

| Flexible Power & Conveyor Options | Select ABB/SEW motors, PVC/roller/chain conveyors, and 380 V or other supplies for seamless integration. |

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | E100 Small Horizontal Stretch Wrapper |

| Bundle Size | OD 50–100 mm; Length > 1000 mm; Weight 8–100 kg |

| Ring Speed | 20–120 r/min (inverter-driven) |

| Conveyor Speed | 6–12 m/min |

| Power | Approx. 2.5 kW; AC 380 V, 3-Phase, 60 Hz (other voltages optional) |

| Control | PLC & touchscreen HMI; photocell positioning; alarms & diagnostics |

| Tension & Overlap | Adjustable friction wheels; 10–90% overlap via PLC |

| Installation | Flat, hard ground ≥ 1 ton/m²; no foundation required |

| Operation Hours | Up to 7,200 h/year continuous use |

| Material | PE stretch film (50–100 mm wide; OD 100–200 mm) |

| Options | Conveyor lengths; ring sizes; motor brands; pre-stretch frames |

Ready to Boost Your Throughput?

Request a Quote and discover how the E100 can deliver fast, damage-free wrapping with measurable ROI.

The E100 Horizontal Stretch Wrapping Machine is designed for wrapping elongated and irregularly shaped products such as pipes, rods, and profiles. Featuring a compact and robust design, it provides consistent stretch wrapping with adjustable tension and speed settings. Ideal for industrial use, the E100 enhances packaging efficiency and ensures product protection during storage and transport.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

E200 Automatic Horizontal Orbit

The E200 Horizontal Stretch Wrapping Machine is designed for efficient packaging of elongated items like pipes, profiles,

View DetailsE300 Horizontal stretch wrappin

The E300 Horizontal Stretch Wrapping Machine is built for heavy-duty industrial applications, providing secure and effici

View DetailsAutomatic Horizontal Spiral Str

The E400 Horizontal Stretch Wrapping Machine is designed for wrapping large and heavy elongated items such as pipes, pane

View DetailsE500 Orbital Ring Stretch Wrapp

Engineered for long, bulky loads—pipes, rods, panels—the E500 Horizontal Wrapping Machine combines high-speed stretch

View DetailsE600 Horizontal stretch wrappin

The E600 Horizontal Stretch Wrapping Machine is designed for heavy-duty wrapping of long and irregular items, such as pip

View DetailsE1000 Orbital Ring Stretch Wrap

The E1000 Horizontal Stretch Wrapping Machine delivers uniform, secure wrapping for oversized panels, pipes, and profiles

View DetailsE1400 Horizontal Orbital Stretc

The Big-Size Orbital Stretch Wrapping Machine is specifically designed for wrapping large items such as doors and panels.

View DetailsE1800 Automatic Horizontal Pane

The E1800 Horizontal Orbital Stretch Wrapper delivers heavy-duty, consistent, uniform wrapping for large items—doors, p

View DetailsE2400 Horizontal stretch wrappi

The E2400 Horizontal Stretch Wrapping Machine specializes in secure packaging of extra-large, heavy-duty items—panels,

View Details