E1400 Horizontal Orbital Stretch Wrapper

Project Information

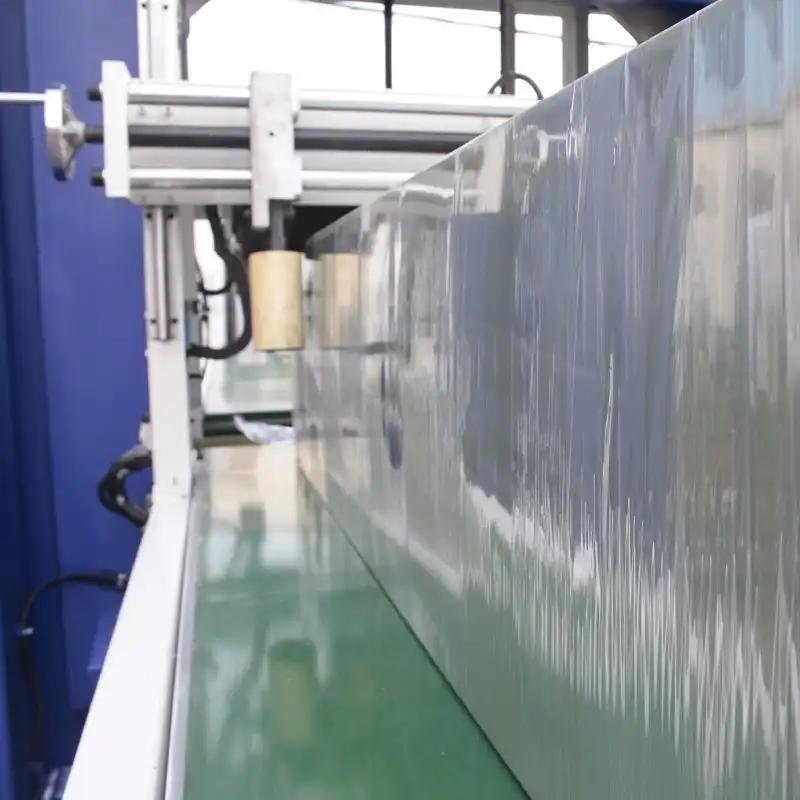

The Orbital Ring Stretch Wrapper & Film Wrapping Machine is a versatile, efficient solution for packaging long, bundled, or delicate items such as trays, profiles, and fragile goods. Combining automation with sustainability, it enhances packaging speed, reduces labor costs, and ensures product protection.

Key Features:

Reinforced Ring: Adjustable speed and friction for secure wrapping

Auto Handling: Film feeds, cuts, and tensions automatically

Soft Conveyor: Protects products with smooth transport

Custom Settings: 10%–90% overlap, tension, and speed control

Safety Shielding: CE-compliant guards and soft start/stop

Automate wrapping of doors, panels, and large items—eliminate tension inconsistencies, surface damage, and manual handling for fast, unmanned cycles.

Key Benefits

- Increase Throughput: PLC/HMI automated cycles reduce manual steps and speed up packaging.

- Save Film: Precise tension and 10%–90% overlap control minimizes material waste.

- Protect Surfaces: Press-down clamps and support rollers prevent vibration and scratches.

- Quick Deployment: Foundation-free design installs on flat floors, cutting setup time and cost.

- Ensure Safety: CE-compliant guards, soft start/stop, and auto alarms protect operators.

Features & Benefits

| Feature / Component | Benefit / ROI |

|---|---|

| Double-Ring & Double-Rubber-Wheel Drive | Stable, high-torque rotation for loads up to 1400 mm wide; ensures uniform tension and fewer defects. |

| PLC/HMI-Controlled Sequences | Fully automates wrap cycles with sensor positioning; reduces errors and boosts line speed. |

| Inverter-Controlled Speeds | Tailors ring and conveyor speeds to product size and material; optimizes cycle time and film use. |

| Centering Entry Conveyor & Auto Positioning | Automatically aligns items before wrapping; eliminates manual repositioning and line stoppages. |

| Adjustable Tension & Overlap (10%–90%) | Fine-tunes film tension and overlap for varied package sizes; prevents loose wraps and cuts costs. |

| Protective Press-Down & Support Rollers | Clamps items securely to prevent movement; protects surfaces from scratches. |

| Flat-Ground Installation | No foundation needed—installs quickly on flat floors, reducing setup expenses. |

| Guardrails, Safety Covers & Auto Alarms | CE-compliant guards and fault alerts enhance operator safety and minimize downtime. |

| Automatic Feeding, Clamping & Cutting | Hands-free film feed, tension, clamp, and clean cut at cycle end—saves labor. |

| Wide Film Frame (up to 500 mm) | Supports broader films for larger packages, improving wrap stability and appearance. |

Technical Parameters

| Parameter | Specification |

|---|---|

| Object Size | Length: 1000-3000mm, Width: 300-1400mm, Height: 50-1000mm |

| In-Feeding Conveyor Length | 2000mm |

| Out-Feeding Conveyor Length | 2000mm |

| Speed | 4~15m/min |

| Ring Speed | 10-60r/min |

| Power Output | About 4.5kw |

| Power Voltage | AC 380v, 60Hz, 3Phase |

| Material | Paper / LLDPE Stretch Film / PE Film / PVC Width: 300/500mm, OD: 200-300mm, ID: 50mm |

The Big-Size Orbital Stretch Wrapping Machine is specifically designed for wrapping large items such as doors and panels. With a robust rotating mechanism and adjustable settings, it ensures secure and uniform packaging for oversized products. Ideal for industrial applications, this machine enhances product protection and streamlines packaging processes for bulky items.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Small Horizontal Stretch Wrappe

The E100 Horizontal Stretch Wrapping Machine is designed for wrapping elongated and irregularly shaped products such as p

View DetailsE200 Automatic Horizontal Orbit

The E200 Horizontal Stretch Wrapping Machine is designed for efficient packaging of elongated items like pipes, profiles,

View DetailsE300 Horizontal stretch wrappin

The E300 Horizontal Stretch Wrapping Machine is built for heavy-duty industrial applications, providing secure and effici

View DetailsAutomatic Horizontal Spiral Str

The E400 Horizontal Stretch Wrapping Machine is designed for wrapping large and heavy elongated items such as pipes, pane

View DetailsE500 Orbital Ring Stretch Wrapp

Engineered for long, bulky loads—pipes, rods, panels—the E500 Horizontal Wrapping Machine combines high-speed stretch

View DetailsE600 Horizontal stretch wrappin

The E600 Horizontal Stretch Wrapping Machine is designed for heavy-duty wrapping of long and irregular items, such as pip

View DetailsE1000 Orbital Ring Stretch Wrap

The E1000 Horizontal Stretch Wrapping Machine delivers uniform, secure wrapping for oversized panels, pipes, and profiles

View DetailsE1800 Automatic Horizontal Pane

The E1800 Horizontal Orbital Stretch Wrapper delivers heavy-duty, consistent, uniform wrapping for large items—doors, p

View DetailsE2400 Horizontal stretch wrappi

The E2400 Horizontal Stretch Wrapping Machine specializes in secure packaging of extra-large, heavy-duty items—panels,

View Details