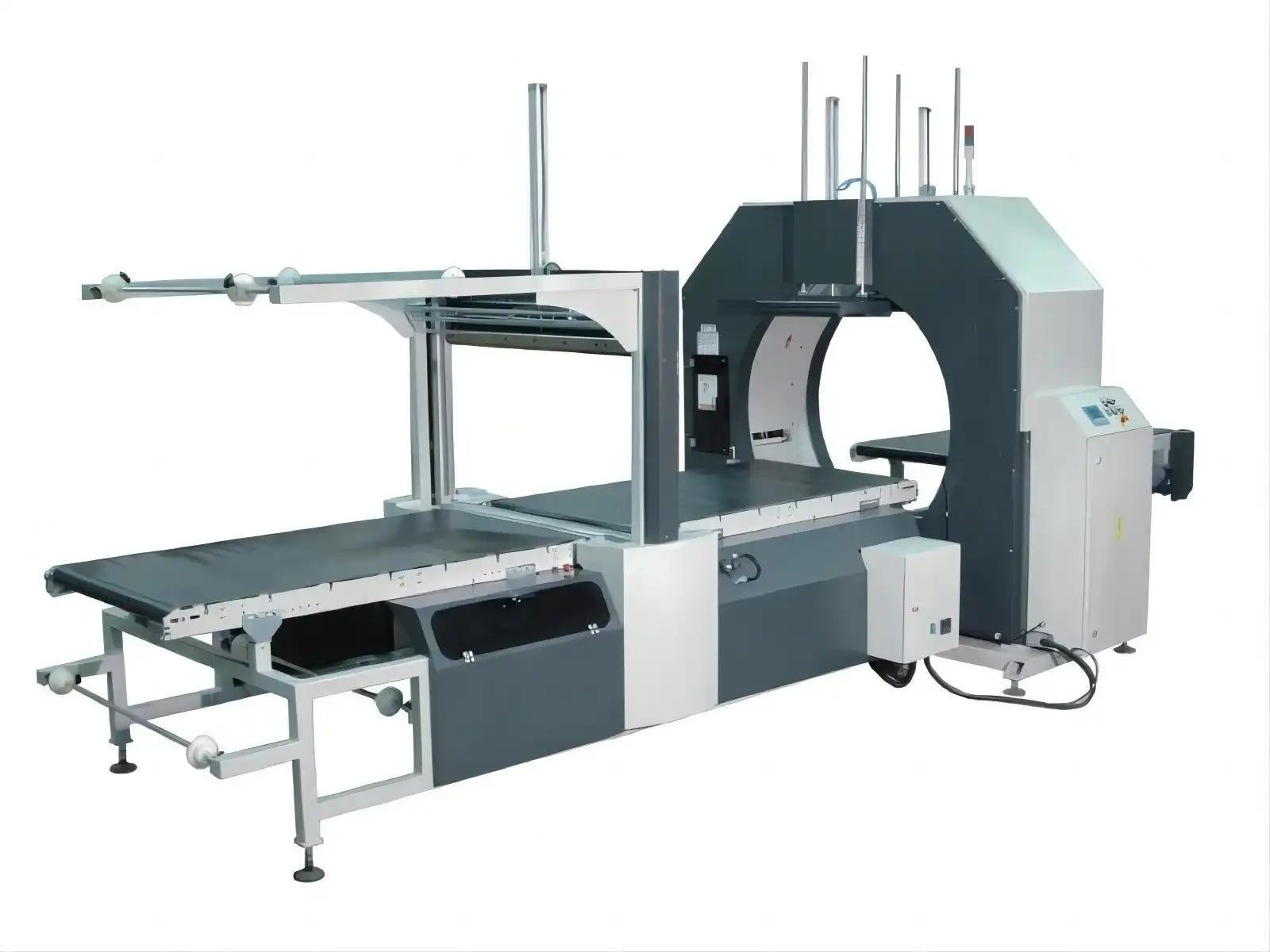

E500 Orbital Ring Stretch Wrapper

Project Information

The Bubble Film Covering and Film Wrapping Orbital Horizontal Stretch Wrapper is an advanced packaging solution designed to provide full coverage for long-shaped products like wooden boards, sofas, panels, and fragile items. Combining bubble film covering with stretch film wrapping, it ensures superior product protection, efficient automation, and professional packaging results.

Key Features:

Dual wrap: bubble film + stretch film

Auto feed, cut & wrap

Adjustable tension, overlap & speed

CE safety shields & soft presses

Intuitive HMI/PLC touchscreen control

Why Manual Wrapping Falls Short

- High Labor & Slow Cycles: Operators spend hours adjusting and feeding film—driving up costs.

- Inconsistent Tension: Uneven wraps lead to loose bundles, wasted film and rework.

- Risk of Damage: Fragile loads can shift, scratch or crush without precise control.

- Complex Changeovers: Swapping ring sizes or friction wheels takes time and expertise.

- Integration Delays: Lengthy commissioning and reconfiguration slow your line starts.

Meet the Automatic Spiral Orbital Stretch Wrapper

Designed for OD 200–600 mm loads (or custom), this system combines PLC/HMI automation with IoT monitoring to deliver fast, reliable, damage-free wrapping and clear ROI.

Key Benefits at a Glance

- Custom Rings & Light Alloy: Handle varied diameters without heavy tooling—cut changeover time.

- Quick-Swap Friction Wheels: Fine-tune tension in seconds—reduce film waste and downtime.

- Inverter-Controlled Speed: Match wrap rate (10–60 r/min) to load and film—optimize cycle time.

- Hands-Free Feeding & Cutting: Automate film feed, clamp and clean cut—slash labor needs.

- Press-Down & Soft Rollers: Secure and protect surfaces—prevent shifting and scratches.

- IoT-Ready PLC/HMI: Run presets, monitor remotely and troubleshoot fast.

Features & ROI

| Feature | Customer Benefit |

|---|---|

| Customizable OD Rings & Aluminum Frame | Adapt to any bundle size—no extra ring inventory or heavy lifts. |

| Adjustable Friction Wheels | Dial in perfect tension—minimize film usage and scrap. |

| Inverter-Driven Ring (10–60 r/min) | Balance speed vs. film stretch—maximize throughput. |

| PLC/HMI with IoT Alerts | Run hands-off cycles and get instant fault notifications. |

| Auto Feed, Clamp & Cut | Complete wrap cycles unattended—reduce staffing needs. |

| Protective Press-Down & Soft Rollers | Keep loads stable and damage-free—cut claims and rework. |

| Quick Conveyor Integration | Plug-and-play station—start wrapping within hours. |

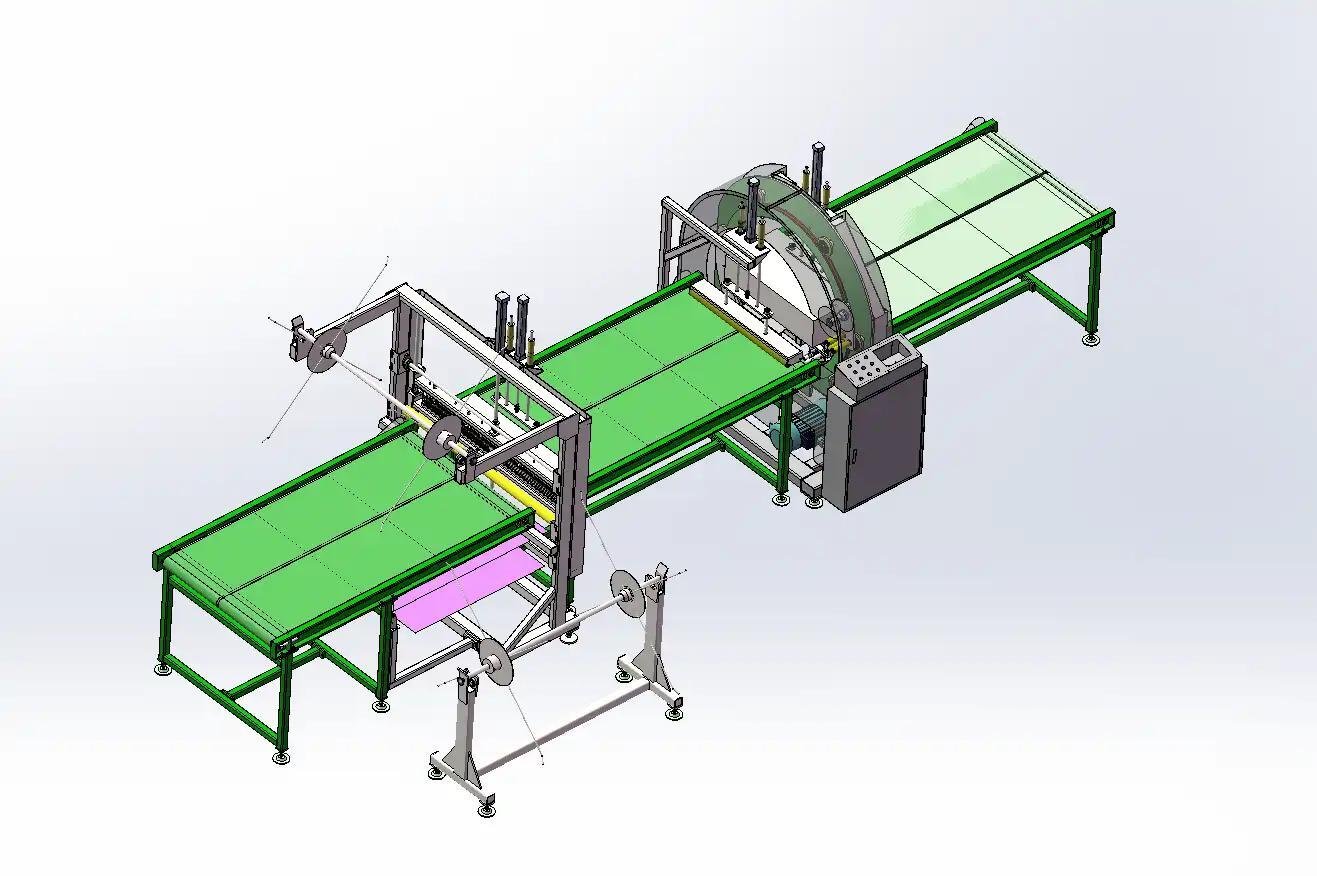

How It Works

- Position Load: Infeed conveyor aligns bundle under the ring.

- Secure & Stabilize: Press-down arms and soft rollers lock load in place.

- Wrap: Ring spins as film carriage applies stretch film with preset tension.

- Cut & Reset: Clamp seals film, clean-cuts automatically, ring returns home.

- Discharge: Outfeed conveyor moves wrapped load downstream—ready for next.

Request Your Custom Quote

Ready to boost speed, cut costs and guarantee damage-free packaging? Contact us with your load specs and throughput targets. Let’s build your tailored solution.

Technical Data

| Parameter | Specification |

|---|---|

| Object Size | Length: >1500mm, Bundle OD: 200-500, Weight: 50-500kg |

| Infeed Conveyor | 2000mm L × 700mm W |

| Outfeed Conveyor | 2000mm L × 700mm W |

| Material Width | 150~300mm |

| Material | LLDPE Stretch Film / Paper / Woven Width: 150-300mm, OD: 100-250mm, ID: 50mm (Let me know, if you need another size) |

| Air Supply | 5~8kgf/cm² |

| Conveyor Speed | 3~12m/min |

| Ring Speed | App. 10-60r/min |

| Machine Size | App. L5200 x W1600 x H1800mm |

| Power Output | About 4.5kw |

| Power Voltage | AC 380v, 50Hz, 3Phase |

| Control Power Voltage | ADC24 |

Contact us to learn more and customize your machine.

Engineered for long, bulky loads—pipes, rods, panels—the E500 Horizontal Wrapping Machine combines high-speed stretch wrapping with adjustable tension and speed controls. Its robust design and intuitive operation deliver consistent, secure packaging, boosting industrial line throughput, product protection, and overall efficiency.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Small Horizontal Stretch Wrappe

The E100 Horizontal Stretch Wrapping Machine is designed for wrapping elongated and irregularly shaped products such as p

View DetailsE200 Automatic Horizontal Orbit

The E200 Horizontal Stretch Wrapping Machine is designed for efficient packaging of elongated items like pipes, profiles,

View DetailsE300 Horizontal stretch wrappin

The E300 Horizontal Stretch Wrapping Machine is built for heavy-duty industrial applications, providing secure and effici

View DetailsAutomatic Horizontal Spiral Str

The E400 Horizontal Stretch Wrapping Machine is designed for wrapping large and heavy elongated items such as pipes, pane

View DetailsE600 Horizontal stretch wrappin

The E600 Horizontal Stretch Wrapping Machine is designed for heavy-duty wrapping of long and irregular items, such as pip

View DetailsE1000 Orbital Ring Stretch Wrap

The E1000 Horizontal Stretch Wrapping Machine delivers uniform, secure wrapping for oversized panels, pipes, and profiles

View DetailsE1400 Horizontal Orbital Stretc

The Big-Size Orbital Stretch Wrapping Machine is specifically designed for wrapping large items such as doors and panels.

View DetailsE1800 Automatic Horizontal Pane

The E1800 Horizontal Orbital Stretch Wrapper delivers heavy-duty, consistent, uniform wrapping for large items—doors, p

View DetailsE2400 Horizontal stretch wrappi

The E2400 Horizontal Stretch Wrapping Machine specializes in secure packaging of extra-large, heavy-duty items—panels,

View Details