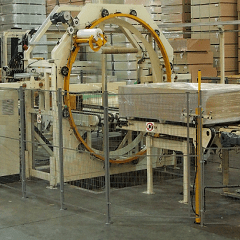

Panel Horizontal Orbital Stretch Wrapper

Project Information

The Automatic Packaging Solution for Wooden Boards and Panels is a highly efficient and eco-friendly system designed to streamline packaging operations for wooden boards, panels, and similar products. Utilizing recyclable stretch film, it offers a durable and sustainable packaging method, ensuring secure and professional wrapping while reducing operational costs.

Key Features:

Seamless PLC/HMI control

Adjustable speed & overlap (20–90%)

Recyclable stretch film

Auto alarms & position sensing

Adapts to diverse packaging needs

Reduce labor, cut material waste and protect board quality with our PLC/HMI-driven Panel Horizontal Orbital Stretch Wrapper.

Specifications

| Parameter | Details |

|---|---|

| Package Size | Width: 1000-1500mm, Height: 300-1400mm, Length: 2000-3000mm |

| Ring Speed | 20-50 r/min |

| Power Output | Approximately 10.5 kW |

| Power Voltage | 380V, 3PH, 50Hz (customizable) |

| Packing Material | Stretch Film |

| Material Dimensions | OD: 100-180mm, Width: 300-500mm, ID: 76mm (custom sizes available on request) |

Why You Need This Solution

- Slash Labor Costs: Automate wrapping to free operators for higher-value tasks.

- Minimize Film Waste: Precise tension and overlap cut material use by up to 30%.

- Speed Up Changeovers: HMI presets switch sizes in seconds—no lengthy setup.

- Eliminate Miswraps: Photoelectric detection and auto-reset ensure perfect starts every cycle.

- Boost Line Throughput: Seamless conveyor integration delivers continuous “start-stop” packaging.

- Stay Compliant & Traceable: Integrated alarms and secure data-logging protect settings and record faults.

- Support Sustainability: Use standard recyclable PE film to lower costs and environmental impact.

- Enhance Safety & Reliability: Soft start/stop, enclosed guards and emergency-stop reduce risk.

Key Benefits at a Glance

| Feature | Customer Benefit |

|---|---|

| Dual-Mode PLC/HMI Control | Toggle between automatic line integration and manual feed in one touch—cut training time and errors. |

| Photoelectric Detection & Auto Reset | Guarantee consistent wrap start and reduce rejects by detecting panel entry and resetting wrap ring. |

| Inverter-Driven Ring & Rollers | Dial in tension (20–90% overlap) and speed (20–50 r/min) for secure, uniform wraps that protect edges. |

| Quick Size Changeover | Recall width/height/length presets instantly—no tools, no downtime. |

| Recyclable Film Compatibility | Use OD 100–180 mm PE film to cut material costs and support green initiatives. |

| Integrated Alarms & Data Logging | Get real-time alerts on misalignments or film tears and preserve your last good settings. |

| Modular, Compact Design | Fit into tight layouts with minimal foundation work—and access components in minutes. |

| Energy-Efficient Drives | Optimize motor use with soft start/stop cycles and inverter controls to lower power bills. |

How It Works

- Detect & Measure: Photoelectric sensors spot the panel and record its dimensions.

- Select Mode: Choose automatic sync with conveyors or manual feed via touchscreen.

- Wrap Cycle: PLC spins the ring; film dispenses with preset tension and overlap.

- Monitor & Alert: Sensors watch for tears or misalignments—machine stops and alarms if needed.

- Log & Recover: All parameters and faults are logged; restore settings with one tap.

- Discharge & Repeat: Wrapped panel exits; ring auto-resets for the next high-speed cycle.

Ideal for These Industries

- Wood & Panel Manufacturers: Wrap plywood, MDF, OSB, and laminated boards consistently.

- Furniture Components: Protect cabinet doors, tabletops and large panels.

- Aluminum & Metal Bundles: Secure profiles and metal sections with precise tension control.

- Contract Packaging & 3PL: Handle variable sizes and materials with traceable data logs.

- Building Material Distributors: Package boards for diverse climates and shipments.

Get Your Customized Quote

Ready to automate panel packaging, slash costs and improve throughput? Contact us today for tailored recommendations, technical drawings and competitive pricing.

The Panel Horizontal Orbital Wrapping Machine is specifically designed for wrapping flat panels, boards, and similar large items. Its horizontal orbital mechanism ensures secure and consistent packaging with stretch film. Equipped with adjustable settings and a durable build, it enhances product protection and improves packaging efficiency in industrial applications.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Pipe Horizontal Orbital Wrappin

The Pipe Horizontal Orbital Wrapping Machine is engineered for efficient and secure packaging of pipes and cylindrical it

View DetailsHorizontal Orbital Wrapping Mac

The Horizontal Orbital Wrapping Machine for Rod and Bar is designed to provide efficient and secure packaging of long, sl

View DetailsAluminum Horizontal Orbital Wra

Optimize aluminum profile packaging with PLC/HMI-controlled centering rollers and quick material change. Request a quote

View DetailsProfile Horizontal Orbital Wrap

The Profile Horizontal Orbital Wrapping Machine E1400 is designed for efficient and secure wrapping of profiles, rods, an

View DetailsSpiral Orbital Wrapper

The Spiral Orbital Wrapper is a versatile packaging machine designed for wrapping elongated items like pipes, rods, and p

View DetailsHorizontal Ring Stretch Wrapper

The Horizontal Ring Stretch Wrapper is a high-performance packaging machine designed for wrapping long and irregular item

View DetailsHorizontal Stretch Wrapping Mac

The Horizontal Stretch Wrapping Machine for Pallets is designed to securely wrap palletized loads horizontally, ensuring

View DetailsHorizontal Orbital Stretch Wrap

The Horizontal Orbital Stretch Wrapper is engineered for wrapping long and irregularly shaped items with a secure stretch

View DetailsFurniture stretch wrapping mach

The Furniture Stretch Wrapping Machine is designed for securely packaging furniture and bulky items with stretch film. Id

View DetailsEPS Panel Wrapping Machine

The EPS Packing Machine is designed for efficient and secure packaging of expanded polystyrene (EPS) products. Ideal for

View DetailsSix Sided Horizontal Orbital St

The Six-Sided Horizontal Orbital Stretch Wrapper for Board offers complete wrapping coverage for boards and flat items, e

View Details