Semi-Automatic Horizontal Stretch Wrapper S300

Project Information

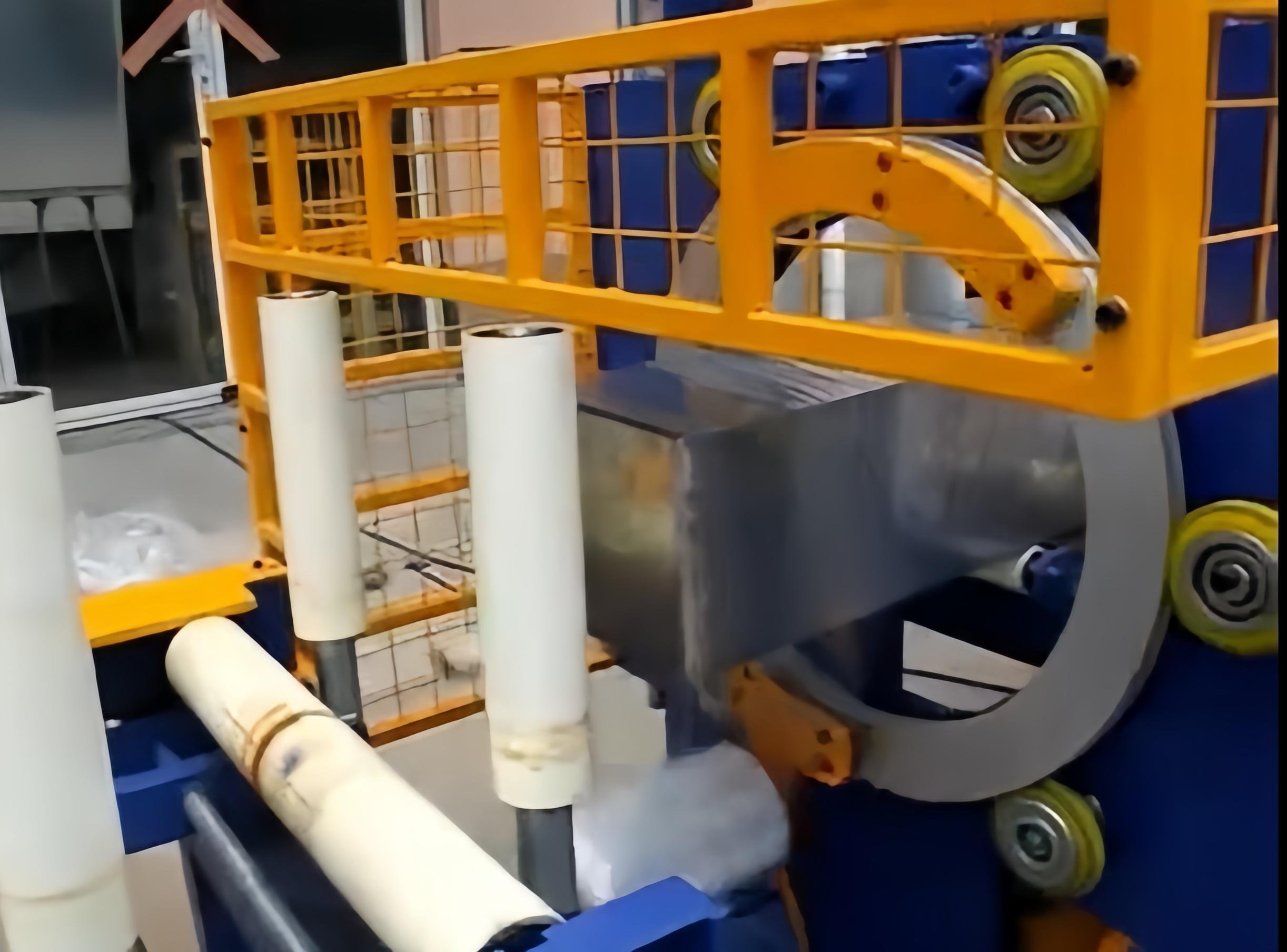

The Semi-Automatic Horizontal Stretch Wrapper is engineered for precision and ease, making it ideal for wrapping horizontal products like pipes, tubes, bars, and floorboards. Its robust design ensures protection, a professional finish, and operational efficiency for various industries.

Key Advantages

Quick Install: Just power and air hookups.

Stable & Safe: Friction wheels for smooth operation.

Automated Control: PLC & sensors for precision wrapping.

Adjustable Settings: Customize overlap and tension.

Secure Hold: Support rollers prevent shifting.

Packaging long, horizontal items like pipes, profiles or timber often means uneven tension, wasted film and slow cycles. The Semi-Automatic Horizontal Stretch Wrapper uses a lightweight aluminum-alloy ring and 100 rpm orbital rotation to deliver precise, repeatable wraps—and plugs right into your line with only power and air.

The Solution: Precision, Speed & ROI

- Consistent Tension & Film Savings: PU traction wheels maintain even wrap tension and cut film waste by up to 30%.

- Faster Cycles: High-speed ring rotation slashes cycle times by ~20%, boosting throughput.

- Hands-Free Control: PLC interface and photoelectric sensors automate wrap parameters and part detection.

- Quick Film Changes: Tool-free, quick-release carriage reduces roll-change downtime by 25%.

- Secure Handling: Support rollers and position-fixing devices keep items steady—no more rework.

- Plug-and-Play Installation: Fits existing lines with just power and air connections.

- Built-In Safety: Friction-wheel safety stops and alarms protect operators and prevent downtime.

Feature – Benefit / ROI

| Feature | Benefit / ROI |

|---|---|

| Aluminum-Alloy Rotating Ring | Low inertia at 100 rpm speeds cuts cycle times ~20% and lowers maintenance. |

| PU Traction Wheels & Adjustable Drive | Reliable grip prevents slip; fine-tune tension to reduce film use up to 30%. |

| PLC & Photoelectric Sensors | Automated cycles and part sensing eliminate operator error and boost uptime. |

| Quick-Release Film Carriage | Tool-free loading cuts roll-change downtime by 25%. |

| Adjustable Overlap & Tension | Optimize wrap strength and material use for every profile. |

| Support Rollers & Fixing Devices | Secure long items on conveyor—no shifting, no rework. |

| Automatic Clamping & Cutting | Tidy film cuts and auto clamp boost efficiency and safety. |

| Simple Power & Air Installation | Minimal setup cost and fast commissioning. |

| Friction-Wheel Safety & Alarms | Immediate alerts on issues protect operators and machines. |

| Custom Conveyor Options | Adaptable to rollers or PVC tables for any product line. |

Ready to Transform Your Line?

Contact us today for a custom layout, detailed specs and competitive pricing—experience streamlined, high-speed horizontal wrapping with measurable ROI.

Technical Parameter S300

| Parameter | Specification |

|---|---|

| Length | >1000mm |

| OD | 50-300mm |

| Entrance Conveyer Length | 2000mm |

| Outlet Conveyer Length | 2000mm |

| Ring Speed | 100r/min |

| Power Output | app. 1.5kw |

| Power Voltage | AC 380v, 60Hz |

| Material | Stretch film Width: 120mm OD: 250mm ID: 50mm |

The Semiauto Horizontal Orbital Wrapping Machine S300 is designed for versatile and efficient wrapping of elongated or irregular items. It combines semi-automatic operation with adjustable settings, ensuring reliable performance across diverse applications. Built for durability and ease of use, the S300 enhances packaging protection while optimizing productivity in industrial environments.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Semiauto horizontal orbital wra

The Semiauto Horizontal Orbital Wrapping Machine S200 offers reliable and efficient wrapping for elongated products. Desi

View DetailsEconomic Horizontal Orbital Str

The Semiauto Horizontal Orbital Wrapping Machine S100 is ideal for lightweight and compact product packaging. Designed fo

View Details