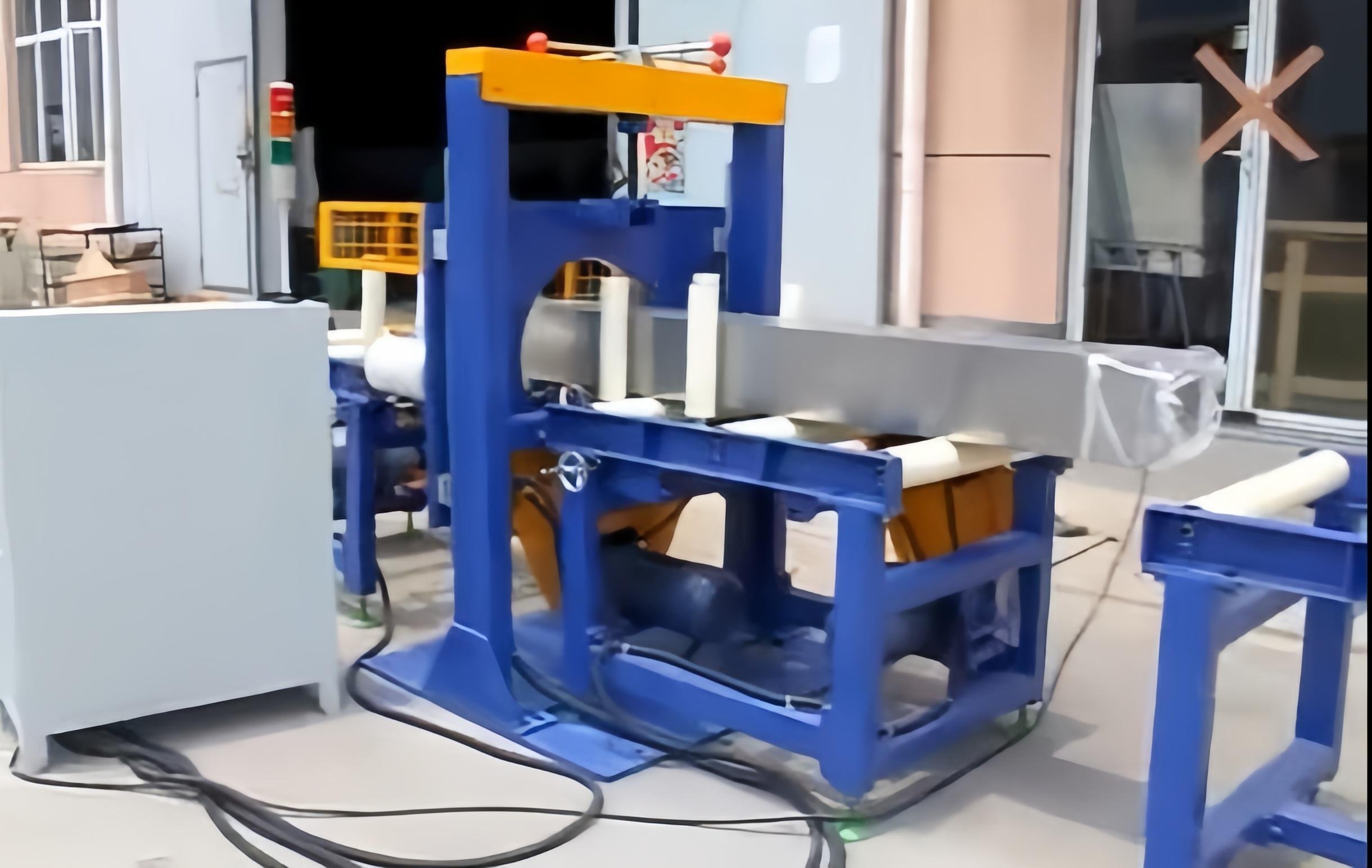

Economic Horizontal Orbital Stretch Wrapper S100

Project Information

The Semi-Automatic Orbital Stretch Wrapper is a reliable and efficient solution for wrapping horizontal products like pipes, bars, and floorboards. Its adaptable design ensures secure and professional packaging, making it ideal for various industries.

Key Features:

Ring-Type Wrapping: Delivers consistent and even coverage.

Adjustable Tension & Overlap: Customizable for different wrapping needs.

Soft Start/Stop: Ensures smooth operation and longer machine life.

PU-Covered Rollers: Protects product surfaces during handling.

Safety Guardrails: Enhances operator safety during operation.

The Challenge: Balancing Cost & Performance

- Budget Limits vs. Capabilities: Skimping on features leads to uneven wraps and higher long-term costs.

- Poor Line Synchronization: Generic wrappers stall conveyors, creating handling delays and lost throughput.

- Varying Bundle Sizes: Manual diameter and length adjustments slow cycles and tie up operators.

- Inconsistent Wrap Quality: Uneven tension and overlap cause unstable bundles and wasted film.

- Hidden Downtime Costs: Without diagnostics or alarms, troubleshooting drags on and downtime spikes.

- Operator Safety Risks: Missing guardrails and unstable drives expose staff to hazards and compliance issues.

The Solution: Key Features & ROI

| Feature | Benefit / ROI |

|---|---|

| Inline Infeed & Outfeed Conveyors | Integrates hands-free into existing lines—cutting handling time and operator costs. |

| Adjustable Ring Speed (20–100 r/min) | Matches wrap speed to each bundle—minimizing film use and cycle time. |

| Tension & Overlap Control | Ensures stable, uniform bundles—reducing film waste by up to 20 %. |

| PLC/HMI Diagnostics & Alarms | Speeds fault detection—shrinking unplanned downtime and service costs. |

| Guardrails & Stable Drive | Protects operators and keeps bundles centered—avoiding rework. |

| Soft Start/Stop & Reset | Reduces mechanical stress—extending equipment life and uptime. |

| Inverter-Controlled Conveyors | Adapts speed to line demands—smoothly handling all bundle lengths. |

| Centralizing Guides & Rollers | Stabilizes items automatically—eliminating manual repositioning. |

| Multi-Film Compatibility | Supports LLDPE/PE/HDPE—balancing protection and budget needs. |

| Quick-Change Carriage & Cutter | Slashes roll-change times and ensures clean film cuts. |

Wrapping Process Overview

- Detection & Positioning: Infeed conveyor moves bundle into station; PLC/HMI confirms start point.

- Orbital Rotation: Ring spins around bundle at set speed; guardrails and guides hold it steady.

- Film Application: Carriage wraps with preset tension and overlap; soft start/stop ensures smooth feed.

- Monitoring & Alarms: PLC tracks speed, tension, and errors; auto-alerts on film breaks or overloads.

- Cut & Release: Optional cutter severs film; ring resets and outfeed conveyor clears the bundle.

- Next Cycle Ready: Film carriage repositions—minimal operator input required.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Economic Horizontal Orbital Wrapper |

| OD Range | 50–200 mm |

| Length | > 1500 mm |

| Conveyor Lengths | 1000 mm in/out (inverter-driven) |

| Conveying Speed | 4–15 m/min |

| Ring Speed | 20–100 r/min |

| Power | ≈ 1.5 kW, AC 380 V/60 Hz |

| Film Width | 120–200 mm |

| Film Roll OD/ID | 150–200 mm / 50 mm |

| Control | PLC with HMI & alarms |

| Safety | Guardrails, soft start/stop, auto alarms |

| Installation | Power & compressed air only |

| Options | Auto cutter, additional film types, extended conveyors |

Ideal Applications & Industries

- Pipe & Tube Producers: Inline bundle wrapping for shipping and storage.

- Profile & Extrusion Plants: Protect long sections from scratches and shifting.

- Timber & Flooring Manufacturers: Secure boards against moisture and transit damage.

- Furniture Component Suppliers: Wrap rails, frames, and extrusions efficiently.

- 3PL & Contract Packers: Offer cost-effective wrapping for varied client needs.

- Composite & Plastic Fabricators: Ensure stable, non-abrasive packaging.

Why Choose Us?

- Cost-Effective Innovation: Get advanced wrapping features without the premium price.

- Fast, Plug-&-Play Integration: Minimal setup—power and air only—so you start wrapping immediately.

- Operator-Friendly Design: Intuitive HMI, auto-alarms, and quick-change carriage simplify daily use.

- Built-In Safety & Reliability: Guardrails, stable drive, and soft start/stop protect people and equipment.

- Measurable ROI: Reduce film waste, cut labor hours, and boost throughput for rapid payback.

- Dedicated Support: Expert consultation, preventive maintenance, and spare parts—on demand.

Request a Quote

Ready to cut costs and boost packaging performance? Contact us with your bundle specs and throughput goals. We’ll deliver a tailored solution, detailed quote, and full support for seamless integration.

The Semiauto Horizontal Orbital Wrapping Machine S100 is ideal for lightweight and compact product packaging. Designed for semi-automatic operation, it delivers consistent wrapping results with adjustable settings. Its durable construction and user-friendly interface make it a practical solution for industries seeking cost-effective and efficient packaging options.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Semiauto horizontal orbital wra

The Semiauto Horizontal Orbital Wrapping Machine S200 offers reliable and efficient wrapping for elongated products. Desi

View DetailsSemi-Automatic Horizontal Stret

The Semiauto Horizontal Orbital Wrapping Machine S300 is designed for versatile and efficient wrapping of elongated or ir

View Details