Are Manual Mold Handling Methods Costing You Time and Safety?

Manually flipping heavy molds and dies is inefficient and hazardous. Discover how our engineered mold flippers transform this critical operation with automated precision and safety.

Production Line Downtime

Lengthy manual mold rotation and repositioning processes severely limit your press and injection molding productivity.

High Labor Intensity & Cost

Relying on multiple workers and overhead cranes for simple mold flips increases labor costs and operational complexity.

Critical Safety Hazards

Unstable manual handling poses severe crush and impact risks to personnel, threatening workplace safety.

Mold Damage & Precision Loss

Improper handling during flipping can cause costly damage to critical mold surfaces and components.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Mold Flipper Manufacturing Excellence

A mold flipper is a specialized machine designed to rotate or flip molds safely and efficiently during manufacturing processes. It reduces manual handling, minimizes the risk of damage to molds, and improves workplace safety. With its precise and reliable operation, a mold flipper is essential for industries working with heavy or complex molds.

Mechanical upender

Discover affordable solutions for handling heavy materials with our mechanical coil upender, coil tilter, and mold upending machine. Designed for efficiency and safety, these machines simplify operations while reducing costs. Perfect for industries needing reliable equipment without breaking the budget. Upgrade your workflow today with our competitively priced, high-performance machinery tailored

Hydraulic upender

A hydraulic upender is an industrial machine designed to safely and efficiently tilt or rotate heavy loads, such as steel coils, molds, or other bulky items. Using hydraulic power, it ensures precise handling, reduces labor strain, and enhances workplace safety. Its robust construction and customizable features make it ideal for manufacturing, warehousing, and heavy-duty operations.

Coil Upender

Find reliable solutions for heavy material handling with our coil upender, designed to improve efficiency and safety in industrial operations. Partner with a trusted coil upender manufacturer to ensure high-quality, durable equipment tailored to your specific needs. Enhance your workflow today with innovative and cost-effective solutions for your business.

Mold Upender

Enhance your mold handling operations with our mold upender, mold tilter, and mold turning machine. Designed for precision and safety, these machines simplify the process of tilting and rotating heavy molds. Ideal for various industries, they improve efficiency, reduce labor effort, and ensure smooth operations. Invest in reliable, high-performance equipment tailored to your production needs.

Mold Flipper

A mold flipper is a specialized machine designed to rotate or flip molds safely and efficiently during manufacturing processes. It reduces manual handling, minimizes the risk of damage to molds, and improves workplace safety. With its precise and reliable operation, a mold flipper is essential for industries working with heavy or complex molds.

Hydraulic Dumper

Wuxi BuHui’s Hydraulic Dumper delivers effortless elevation and tipping of heavy boxes and containers—streamlining your workflow, boosting throughput, and enhancing operator safety with smooth, reliable performance.

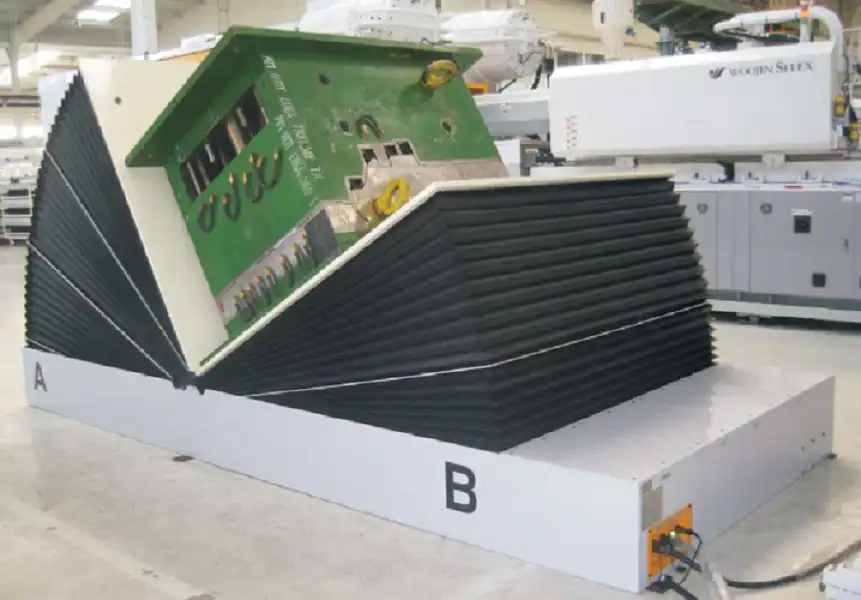

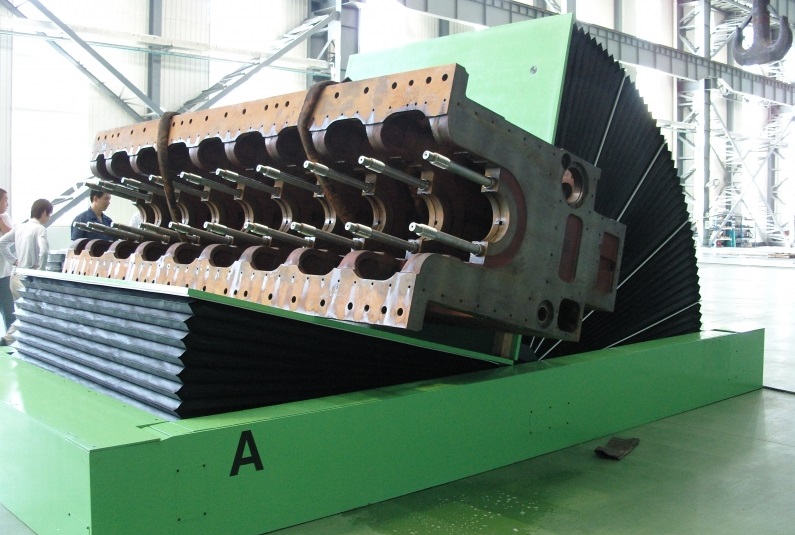

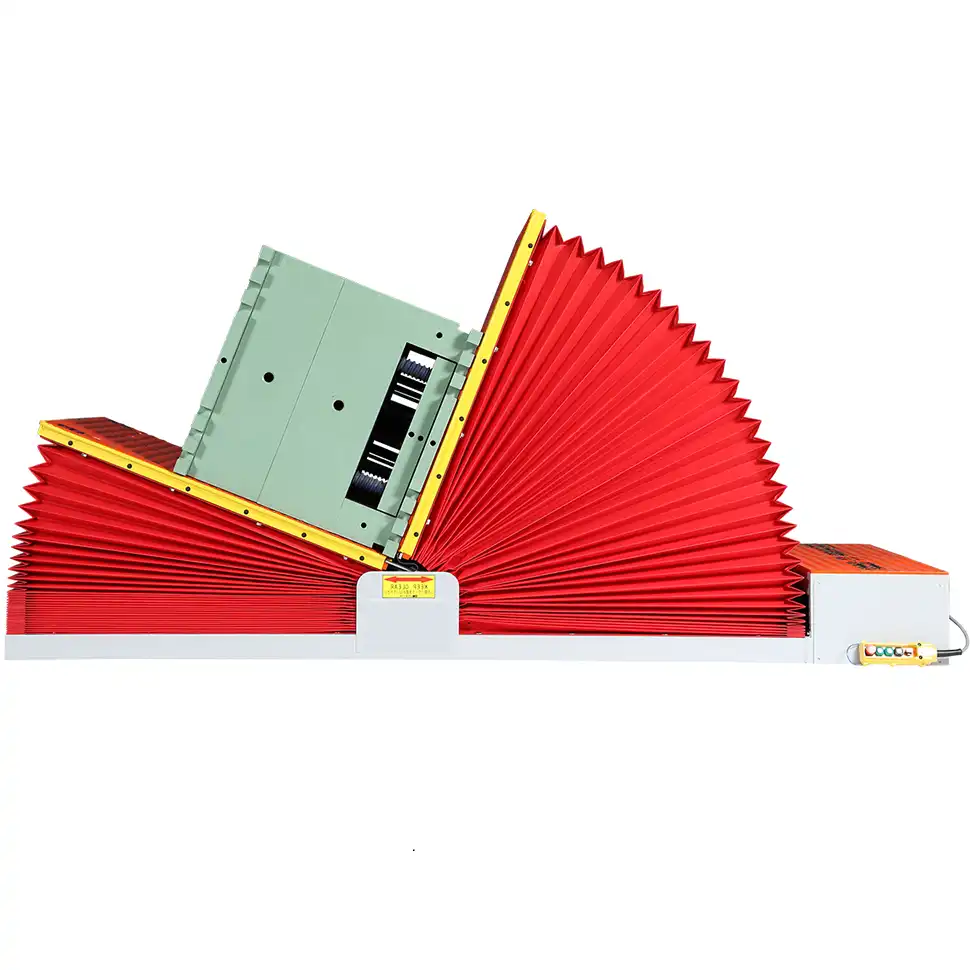

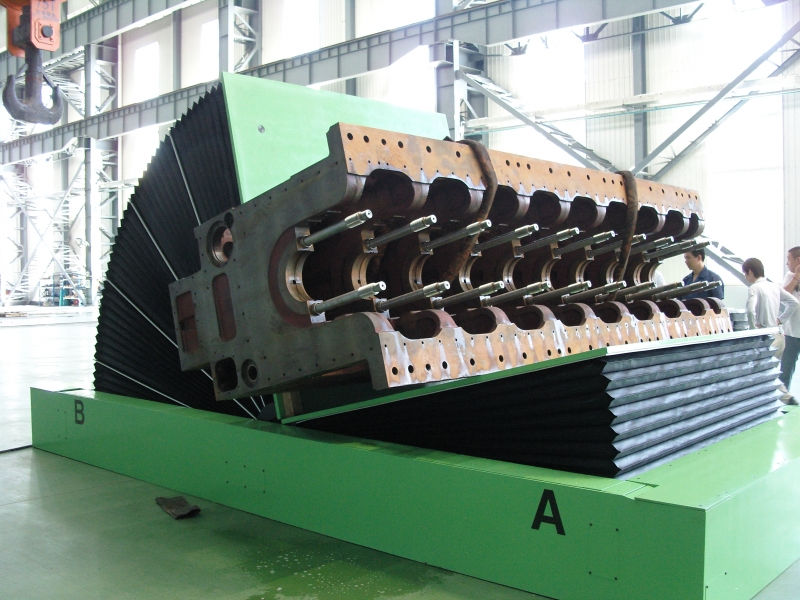

Precision Mold Handling & Flipping Systems

Our engineered mold flipping equipment delivers secure, efficient rotation solutions for heavy industrial molds, integrating robust construction with intelligent control systems to eliminate manual handling risks and optimize workflow productivity.

Heavy-Duty Performance: Engineered for molds up to 30 tons with precision balancing and secure clamping mechanisms.

Adaptive Control Systems: Programmable rotation with multiple safety interlocks and remote operation capabilities.

Space-Optimized Design: Compact footprint with 360-degree rotation capability for limited facility spaces.

Operation Time Saved

Accident Prevention

Labor Reduction

Warranty Coverage

Automotive Manufacturer Implements Mold Flipping Technology

Operational Challenge

A prominent automotive parts producer faced significant production bottlenecks with manual mold handling, experiencing frequent damage incidents and extended mold changeover times affecting their injection molding operations.

Engineering Solution

We installed a customized hydraulic mold flipping table with automated positioning, reducing mold transition time from 45 to 8 minutes. The solution eliminated product damage during rotation and enabled single-operator mold management across three production lines.

Request Your Custom Solution

SHOWCASE & NEWS

Industrial Mold Flipping Equipment FAQ

Expert Answers for Mold Flipper, Mold Flipping Table, and Mold Flipping Machine Solutions

A mold flipping machine is a specialized industrial device designed to safely rotate and reposition heavy molds during manufacturing processes. It eliminates manual handling risks by providing controlled, hydraulic-powered rotation with precision positioning. These systems incorporate safety features like emergency stops, anti-slip platforms, and overload protection. By removing workers from direct contact with heavy loads, mold flipping equipment reduces workplace injuries by up to 85% while ensuring consistent, damage-free mold handling for injection molding, die casting, and other industrial applications.

Our mold flipping equipment comes in various configurations to handle diverse industrial requirements. Standard models support weights from 1 to 30 tons, with custom solutions available for heavier applications up to 50 tons. Platform sizes range from compact 1x1 meter tables for smaller molds to large 3x2 meter surfaces for oversized tooling. The flipping mechanisms provide 90 to 180-degree rotation with precision control. We engineer each system with adjustable clamping options and customizable interface heights to seamlessly integrate with your existing production layout and mold handling workflow.

Automated mold flipping solutions deliver substantial cost savings by streamlining mold maintenance and changeover processes. These systems reduce mold flipping time from 30-45 minutes manually to just 2-3 minutes automatically, cutting labor requirements by 70%. By preventing mishandling damage, they eliminate expensive mold repairs that typically cost $5,000-$15,000 per incident. The precision engineering minimizes wear on mold components, extending tool life by 25-40%. Overall, manufacturers achieve ROI within 8-18 months through reduced labor costs, minimized damage, and increased production uptime.

Most standard mold flipping machines operate on 480V 3-phase power with consumption ranging from 15-40 amps depending on model size. Facility requirements include adequate floor space (typically 1.5x the machine footprint for operational clearance), reinforced concrete flooring capable of supporting concentrated loads, and proper lighting for visual inspections. We provide detailed site preparation guidelines including foundation specifications, utility connection points, and environmental considerations. Installation typically requires 3-5 days with our supervision, including positioning, utility connections, calibration, and operator training.

Yes, our mold flipping equipment is designed for seamless integration with existing material handling infrastructure. We engineer compatibility with overhead crane systems, providing adequate clearance heights and reinforced lifting points. Custom interface options include roller conveyors, turntables, and automated transfer systems to connect with your production line. Control systems can be synchronized with plant-wide automation networks using standard industrial protocols. Our engineering team conducts pre-installation assessments to ensure optimal integration with your specific crane capacities, floor layout, and workflow patterns for maximum operational efficiency.

We offer comprehensive maintenance packages including scheduled service visits, emergency support, and remote monitoring options. Our preventive maintenance program includes quarterly inspections, hydraulic system analysis, structural integrity checks, and safety system verification. Technical support is available 24/7 with average response times under 2 hours for critical issues. We maintain an extensive inventory of spare parts including hydraulic cylinders, rotation motors, and control components. Customers receive detailed maintenance documentation, operator training programs, and access to our online technical portal for troubleshooting guides and operational manuals.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts