Revolutionize Your Steel Wire Packaging Process

Experience next-generation automation with our intelligent steel wire rewinding and packaging systems, designed to maximize efficiency while minimizing operational costs.

Fully Automated Operation

Our automated steel wire packing line handles everything from rewinding to strapping, eliminating manual intervention and boosting throughput.

Precision Packaging Quality

Achieve consistent coil winding and secure strapping with advanced tension control systems that prevent damage during transit.

Smart System Integration

Seamlessly connect with MES, ERP, and tracking systems through our intelligent control platforms for complete production visibility.

Significant Cost Reduction

Reduce labor costs by up to 70% and minimize material waste with optimized steel wire, PET, and PE strap utilization.

Join leading steel wire manufacturers who have increased their packaging efficiency by 45% while achieving perfect shipment readiness.

Request Your Custom Solution

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

Wire winding and packing line Manufacturing Excellence

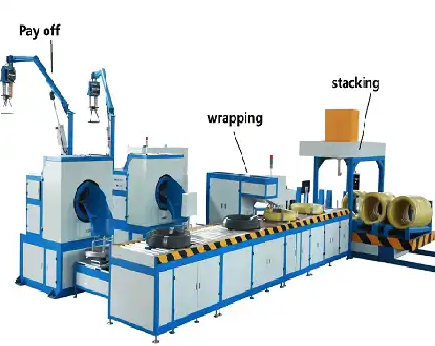

The solution of the Automatic steel wire rewinding and packaging lines that includes the wire rewiding, wire strapping, wire coil wrapping and package stacking. The solution is customzied per different steel wire factory

Wire winding and packing line

The solution of the Automatic steel wire rewinding and packaging lines that includes the wire rewiding, wire strapping, wire coil wrapping and package stacking. The solution is customzied per different steel wire factory

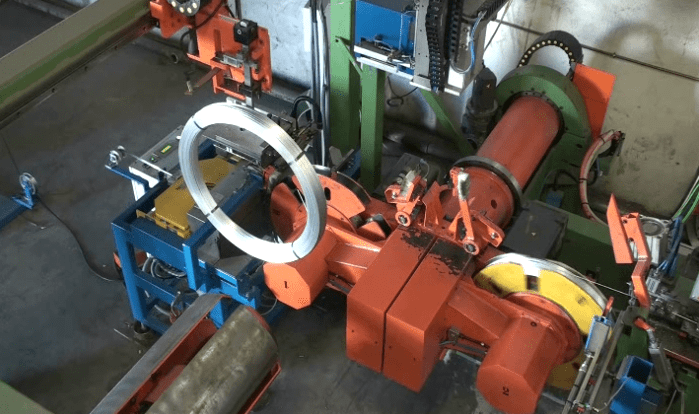

Wire compacting and strapping line

A Wire Compacting and Strapping Line is a specialized system designed to compact and securely strap wire coils or bundles. It ensures precise alignment, efficient compression, and durable strapping for easy handling and transport. This automated solution enhances productivity, reduces labor costs, and guarantees safe and reliable packaging for industrial wire products.

Automated Steel Wire Rewinding & Packaging Systems

Our intelligent steel wire packaging solutions revolutionize coil processing with fully automated rewinding and packing capabilities, delivering precision-engineered systems that transform bulky wire reels into perfectly packaged commercial coils with minimal human intervention.

Integrated Processing Line: Seamless integration of rewinding, binding, inspection and labeling operations in a single automated system for wire drawing facilities.

Smart Monitoring Systems: Advanced length measurement, weight verification and quality control sensors ensuring packaging precision and consistency.

Digital Integration Ready: Compatible with MES and ERP systems for real-time production tracking, inventory management and operational analytics.

Throughput Improvement

Manual Labor Reduction

Packaging Accuracy Rate

Months ROI Period

Wire Manufacturing Plant Automation Success

Operational Challenge

A prominent steel wire manufacturer faced production bottlenecks with manual coil processing, experiencing inconsistent packaging quality, high labor costs, and inability to meet growing order volumes with their existing conventional packaging methods.

Automated Solution Delivered

We implemented a complete automated steel wire rewinding and packing line featuring precision tension control, multiple binding options (steel wire, PET, PE straps), and full digital integration. The system achieved production of 25-30 perfectly packaged coils per hour with zero defects and 40% reduction in packaging material waste.

Request Technical Specifications

SHOWCASE & NEWS

Automatic Steel Wire Rewinding & Packing Line FAQ

Expert Answers to Your Automated Steel Wire Packaging Questions

An automatic steel wire rewinding and packing line is a complete automation system that transforms large wire reels into precisely wound, securely packaged smaller coils. This integrated solution combines rewinding machinery with automated packaging equipment, utilizing steel wire, PET straps, or PE binding materials to create uniform, transport-ready packages. The system typically includes length verification, weight checking, and advanced tracking capabilities that seamlessly integrate with factory management software.

Automated wire rewinding systems dramatically enhance production throughput by processing 4-6 times more material per hour compared to manual operations. These systems maintain consistent tension and winding patterns, eliminating variations in coil quality. The automation reduces labor requirements by up to 75% while minimizing material waste through precise length control. Production facilities typically achieve ROI within 18 months through increased output, reduced operational costs, and improved product consistency.

Our automatic wire rewinding lines accommodate a comprehensive range of specifications, handling wire diameters from 0.5mm to 8.0mm. Standard systems produce finished coils with diameters ranging from 300mm to 1200mm and weights up to 2,000 kilograms. Custom configurations are available for specialized applications, including fine wire processing below 0.5mm and heavy-duty systems for industrial-grade wire products. The equipment processes various wire types including low-carbon, high-carbon, stainless steel, and specialty alloy wires.

Yes, our rewinding and packing lines feature advanced integration capabilities with major MES and ERP platforms. The systems support real-time data exchange through standard protocols including OPC-UA, REST API, and SQL database connectivity. This enables automatic order processing, production tracking, quality data collection, and inventory management. Each packaged coil can be automatically labeled with barcodes or RFID tags, providing complete traceability throughout your supply chain and seamless integration with your digital factory ecosystem.

Our automated wire packing systems incorporate comprehensive safety systems including emergency stop circuits, light curtains, safety interlocks, and overload protection. The machinery features guarded moving parts, automatic fault detection, and vibration monitoring to prevent accidents. Advanced systems include predictive maintenance alerts and remote monitoring capabilities. These safety features not only protect operators but also prevent equipment damage, reducing unplanned downtime by up to 90% compared to manual packaging operations.

The complete installation and commissioning process typically requires 10-14 weeks from equipment delivery to full production. This includes: 2 weeks for foundation preparation and utility connections, 4-5 weeks for mechanical installation, 3 weeks for electrical and control system integration, 2 weeks for testing and calibration, and 1 week for operator training. Our project management team provides detailed timelines and works closely with your staff to ensure minimal disruption to your existing operations while achieving optimal system performance.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts