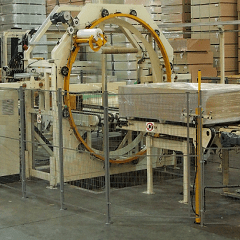

Horizontal orbital stretch wrapper with wooden feeding

Project Information

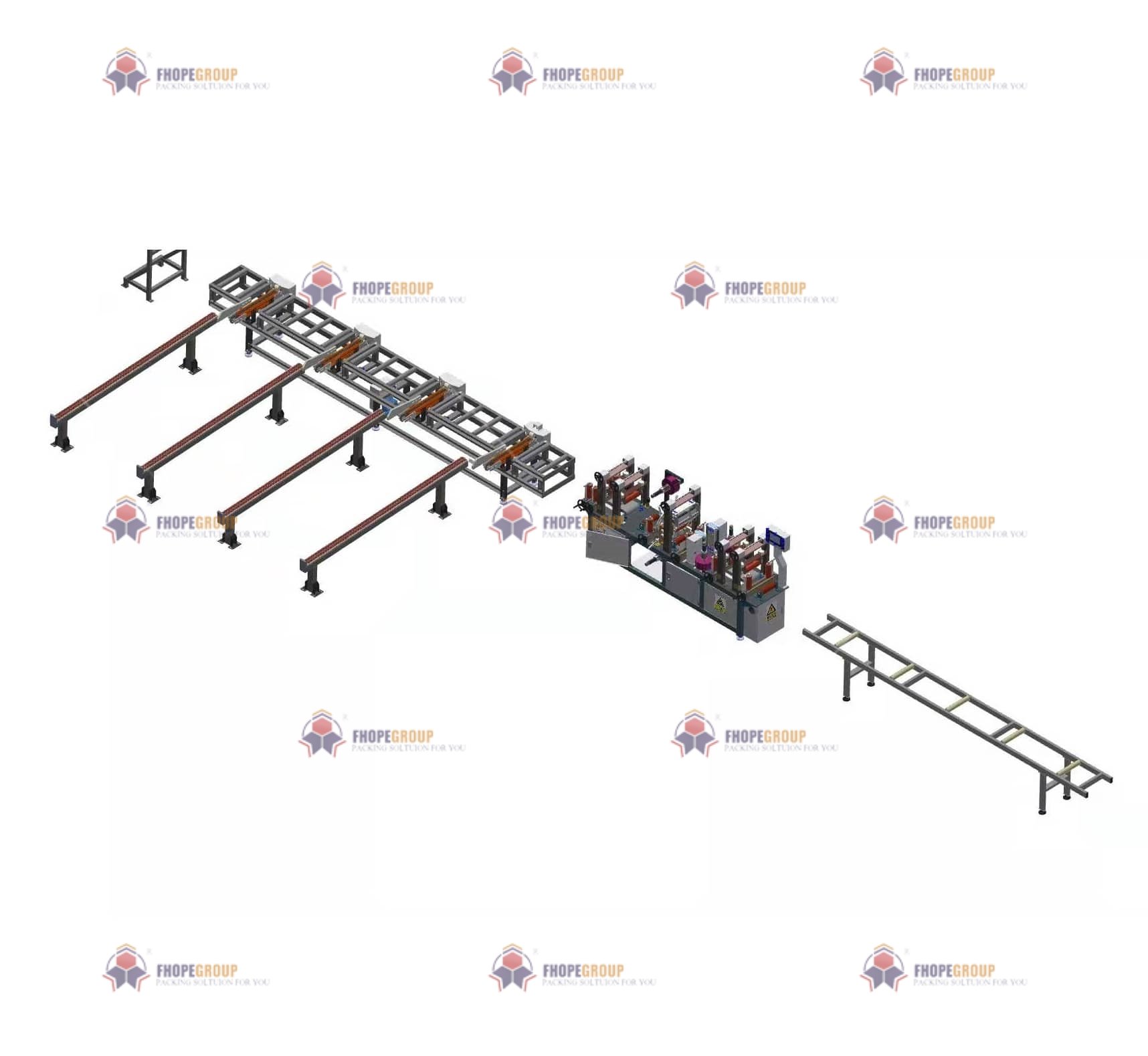

The Automatic Horizontal Stretch Wrapper Machine is an advanced packaging solution designed for long and straight products like profiles, bars, and sheets. With intelligent automation and high-speed operation, it ensures secure and professional packaging while streamlining processes and reducing costs.

Key Features:

Bundling, wrapping & stacking

High-speed, constant-tension wrap

Auto-detect, cut & adjust

Low staffing with intuitive controls

Quick-change design for easy integration

Streamline Timber Bundling & Cut Costs

- Automate feed, wrap & strap in one seamless cycle

- Free up operators—run via PLC/HMI in under 1 minute

- Achieve uniform tension—protect surfaces every time

- Swap film/materials fast—minimize downtime

- Detect tears instantly—avoid rework & delays

- Handle bundles 300×300–500×500×6500 mm

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Automatic Horizontal Orbital Wrapper with Timber Feeder & Strapping |

| Bundle Footprint | 300×300 mm to 500×500 mm |

| Length Capacity | Up to 6500 mm |

| Air Supply | 6–8 bar |

| Power | AC 380 V / 50 Hz |

| Ring Speed | 20–60 r/min (inverter) |

| Wrap Speed | 2–12 m/min (inverter) |

| Film Width | Up to 500 mm |

| Strap Count & Tension | Program via HMI |

| Changeover Time | < 1 minute |

The Challenge

- Uneven wrap tension causing bundle failures

- Multiple operators drive up labor costs

- Integration gaps create line stoppages

- Lengthy material changeovers waste time

- No automatic tear detection delays fixes

- Variable bundle sizes demand flexible handling

Solution: Horizontal Orbital Wrapper with Feeder & Strapping

| Feature / Component | Benefit / ROI |

|---|---|

| Top & Bottom Feeder | Auto-centers timber/profiles—cuts operators & cycle time |

| Inverter-Controlled Orbital Ring | Consistent film tension—reduces waste & surface damage |

| PLC/HMI Control | Set wrap speed, tension & straps easily—no specialists needed |

| Quick-Change Film Frame | Swap materials in<1 min—keep production moving |

| Tear & Roll-End Detection | Stops on fault—prevents bad wraps and rework |

| Programmable Strapping | Auto-apply straps—secure bundles for transport |

| Adjustable Size Handling | Supports 300×300 to 500×500 mm footprints |

| Safety & Diagnostics | Guards, E-stop & HMI alerts—minimize downtime |

Get Your Custom Quote

Ready to boost efficiency and cut costs? Contact us with your bundle specs and integration needs for a tailored solution and competitive pricing.

The Horizontal Orbital Stretch Wrapper with Wooden Feeding is designed for efficient wrapping of long, irregular items with added support from a wooden feeding system. Ideal for materials like rods, pipes, and panels, it ensures stable handling and precise wrapping. With adjustable settings and durable construction, it enhances packaging protection and operational efficiency.

Inquire About This Project

Contact Information

- +8613951501635

- info@cnbhpac.com

- +8613951501635

Related Projects

Pipe Horizontal Orbital Wrappin

The Pipe Horizontal Orbital Wrapping Machine is engineered for efficient and secure packaging of pipes and cylindrical it

View DetailsHorizontal Orbital Wrapping Mac

The Horizontal Orbital Wrapping Machine for Rod and Bar is designed to provide efficient and secure packaging of long, sl

View DetailsAluminum Horizontal Orbital Wra

Optimize aluminum profile packaging with PLC/HMI-controlled centering rollers and quick material change. Request a quote

View DetailsProfile Horizontal Orbital Wrap

The Profile Horizontal Orbital Wrapping Machine E1400 is designed for efficient and secure wrapping of profiles, rods, an

View DetailsSpiral Orbital Wrapper

The Spiral Orbital Wrapper is a versatile packaging machine designed for wrapping elongated items like pipes, rods, and p

View DetailsHorizontal Ring Stretch Wrapper

The Horizontal Ring Stretch Wrapper is a high-performance packaging machine designed for wrapping long and irregular item

View DetailsHorizontal Stretch Wrapping Mac

The Horizontal Stretch Wrapping Machine for Pallets is designed to securely wrap palletized loads horizontally, ensuring

View DetailsHorizontal Orbital Stretch Wrap

The Horizontal Orbital Stretch Wrapper is engineered for wrapping long and irregularly shaped items with a secure stretch

View DetailsFurniture stretch wrapping mach

The Furniture Stretch Wrapping Machine is designed for securely packaging furniture and bulky items with stretch film. Id

View DetailsSix Sided Horizontal Orbital St

The Six-Sided Horizontal Orbital Stretch Wrapper for Board offers complete wrapping coverage for boards and flat items, e

View DetailsBubble Film Orbital Stretch Wra

The Orbital Stretch Wrapper with Bubble Film Covering Device combines stretch wrapping and bubble film application for en

View DetailsPanel Horizontal Orbital Stretc

The Panel Horizontal Orbital Wrapping Machine is specifically designed for wrapping flat panels, boards, and similar larg

View Details