Revolutionize Your Hose Packaging Process Today

Discover how our automated wrapping systems eliminate manual labor challenges while ensuring perfect protection for hose coils and plastic pipes.

Slow Manual Wrapping Processes

Traditional hose coil packaging methods struggle to keep pace with production demands and shipment schedules.

Excessive Material Waste

Inconsistent manual wrapping leads to unnecessary consumption of PE film, paper, and woven materials.

Inadequate Product Protection

Poor wrapping quality exposes hose coils and plastic pipes to damage during storage and transportation.

Limited Production Flexibility

Manual systems cannot efficiently handle diverse hose and pipe sizes, shapes, and packaging requirements.

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

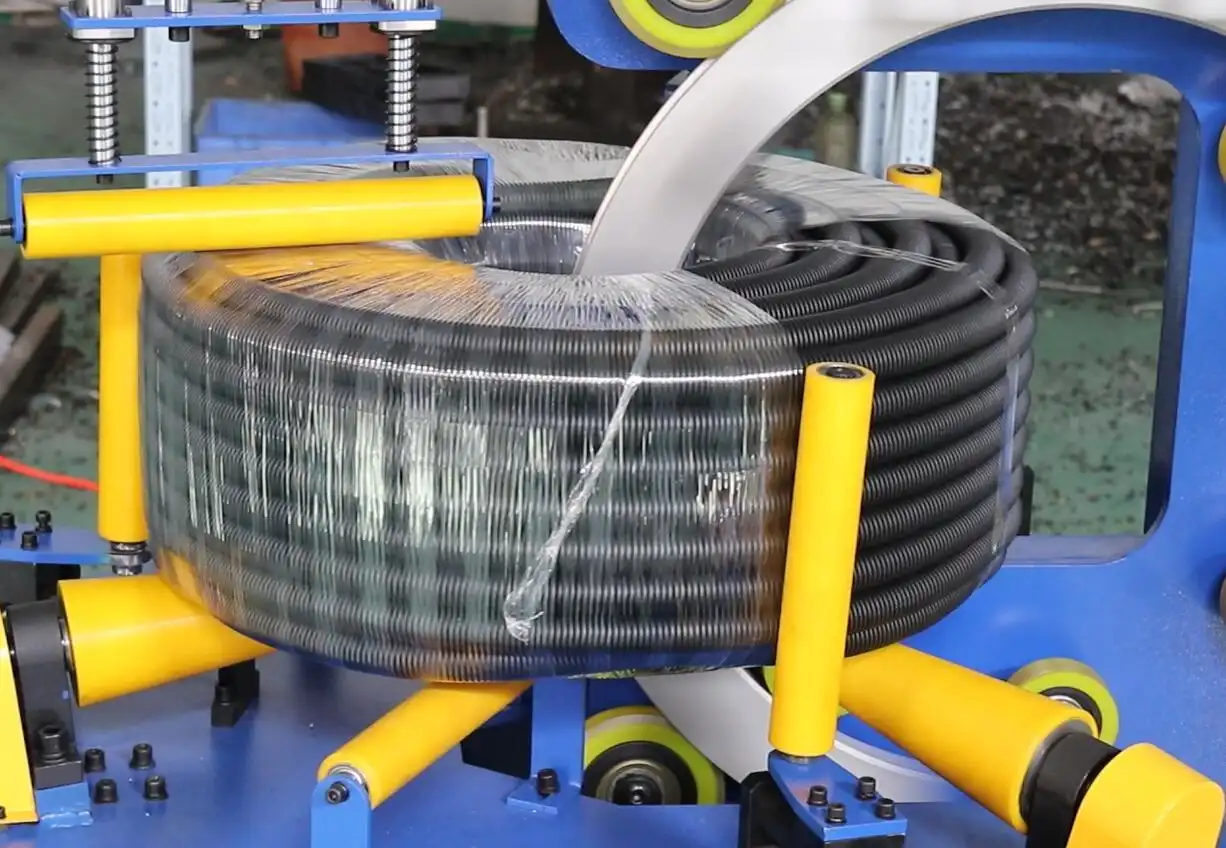

Hose wrapping machine Manufacturing Excellence

Enhance your packaging efficiency with our hose coil wrapping machine and hose packing machine. Engineered for durability and precision, these machines ensure secure and streamlined packaging for hose coils of various sizes. Optimize your workflow and achieve professional-grade results with advanced technology designed to meet your industrial needs.

Steel coil wrapping machine

Discover the ultimate solution for your industrial packaging needs with our Steel Coil Wrapping Machine and advanced Steel Coil Packaging Machinery. Boost efficiency, ensure product safety, and optimize your operations with innovative, reliable equipment designed for high-performance results. Explore the perfect blend of durability and precision for seamless packaging today.

Steel wire wrapping machine

Discover efficient and reliable solutions for your packaging needs with our steel wire wrapping machine and steel wire coil packing machine. Designed to enhance productivity and ensure secure packaging, these advanced machines provide durability and precision for streamlined operations in industrial settings. Optimize your packaging process today with cutting-edge technology.

Hose wrapping machine

Enhance your packaging efficiency with our hose coil wrapping machine and hose packing machine. Engineered for durability and precision, these machines ensure secure and streamlined packaging for hose coils of various sizes. Optimize your workflow and achieve professional-grade results with advanced technology designed to meet your industrial needs.

Copper coil wrapping machine

Streamline your packaging operations with our copper coil wrapping machine and copper coil packing machine. Built for precision and reliability, these machines ensure secure and efficient packaging for copper coils, enhancing product safety and operational efficiency. Upgrade your process with cutting-edge technology designed to meet industrial demands.

Tyre packing machine

Optimize your packaging process with our tyre wrapping machine and tyre packing machine. Designed for durability and precision, these machines provide secure and efficient packaging solutions for tyres of all sizes. Enhance productivity and ensure product protection with advanced technology tailored to your industrial needs.

Cable packing machine

Improve your packaging efficiency with our cable wrapping machine and cable coil packing machine. Designed for reliability and precision, these machines ensure secure and efficient packaging for cable coils of various sizes. Upgrade your operations with advanced technology tailored to meet industrial packaging standards.

Bearing packing machine

Enhance your packaging process with our bearing wrapping machine and bearing packing machine. Engineered for precision and durability, these machines provide secure and efficient packaging solutions for bearings, ensuring product protection and streamlined operations. Optimize your workflow with cutting-edge technology designed for industrial excellence.

Pipe wrapping machine

Boost your efficiency with our advanced pipe coil wrapping machine – the perfect solution for secure, high-speed packing of coils. Designed to handle delicate materials, our plastic pipe coil packing machine ensures superior protection and professional-grade wrapping for optimal transportation. Enhance your operations today!

Advanced Hose Coil Wrapping Systems

FHOPE engineered hose coil wrapping machines deliver precision packaging solutions for industrial hose, plastic pipe, and cable coil applications. Our automated systems eliminate manual wrapping inefficiencies while optimizing material usage across diverse production environments.

Multi-Material Compatibility: Seamlessly handles PE stretch film, kraft paper, LLDPE, and HDPE woven materials for versatile packaging requirements.

Rapid Cycle Performance: Achieves consistent 15-second wrapping cycles per coil, maximizing throughput for high-volume production facilities.

Adaptive Configuration Options: Three specialized wrapping solutions - vertical, horizontal, and fully automated systems - accommodate various coil dimensions and production layouts.

Average Wrapping Cycle

Labor Efficiency Gain

Packaging Consistency Rate

Material Type Compatibility

Hydraulic Hose Manufacturer Boosts Packaging Output

Production Challenge

A leading industrial hose manufacturer struggled with manual coil packaging bottlenecks, experiencing inconsistent wrapping quality and inability to meet rising order volumes. Their existing process consumed excessive labor hours and packaging materials.

FHOPE Automation Solution

We implemented a customized horizontal hose coil wrapping system with automatic feeding and integrated weighing. The results: packaging throughput increased by 240 coils per shift, material waste reduced by 22%, and achieved full ROI within 8 months of operation.

Request Your Custom Solution

SHOWCASE & NEWS

Hose Coil Wrapping Machine FAQ

Expert Answers to Your Hose and Pipe Coil Packaging Questions

Our hose coil wrapping equipment accommodates a diverse range of products including rubber hoses, PVC pipes, irrigation tubing, and flexible conduits. Standard machines handle coil diameters from 300mm to 1500mm with widths up to 1200mm. Special configurations are available for irregular shapes and oversized coils. The systems effectively package various materials including industrial hoses, garden hoses, plastic pipes, and electrical conduit coils with consistent wrapping quality.

Automated hose coil wrapping systems dramatically enhance packaging operations by achieving cycle times as fast as 15 seconds per coil. This represents a 70% reduction in packaging time compared to manual methods. The automation eliminates labor-intensive wrapping tasks, reduces material waste by 25-40% through precise film control, and ensures uniform packaging quality across all production batches. Operations typically see ROI within 8-18 months through labor savings and increased throughput.

FHOPE hose coil wrappers support multiple packaging materials including PE stretch film, kraft paper, LLDPE woven fabric, and HDPE mesh. The machines feature adjustable tension controls and wrapping patterns optimized for each material type. This flexibility allows manufacturers to select the most cost-effective protective wrapping for their specific application, whether requiring weather resistance, UV protection, or enhanced durability for shipping and storage in various environmental conditions.

Vertical hose coil wrappers are ideal for operations with limited floor space and handle coils in an upright position, perfect for standard hose packaging. Horizontal wrappers provide enhanced stability for heavier coils and irregular shapes, offering easier loading for bulky items. Automatic systems combine both orientations with robotic integration for high-volume production facilities. The choice depends on your production volume, available space, coil characteristics, and required packaging speed for your specific manufacturing environment.

Space requirements vary by machine type. Compact vertical models need approximately 6-10 square meters, while horizontal systems require 12-18 square meters including operational clearance. Fully automated lines with conveyor integration may need 20-30 square meters. Our engineering team provides detailed layout planning during the quotation phase to ensure optimal floor space utilization. We also offer modular designs that can be adapted to existing production layouts, minimizing facility modifications while maximizing packaging efficiency.

FHOPE delivers comprehensive post-installation support including on-site operator training, maintenance workshops, and detailed technical documentation. We provide remote troubleshooting assistance and 24/7 technical support hotline for urgent issues. Our service packages include preventive maintenance schedules, spare parts recommendations, and regular software updates. For international clients, we maintain a global network of service technicians ensuring prompt response times. Typical operator training requires 3-5 days covering machine operation, basic troubleshooting, and routine maintenance procedures.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts