FHOPE Customized Orbital Wrapping Machines

Stop compromising with standard wrapping equipment. Our engineered orbital wrapping systems are precisely configured for your unique product shapes and protection requirements.

Tailored Configuration

Customized orbital wrapping machines adapted to your exact product dimensions and packaging specifications.

Advanced Flexibility

Adjust wrapping patterns, speed, and tension to accommodate diverse product shapes and materials.

Superior Protection

Ensure complete coverage and consistent packaging quality for even the most irregular product geometries.

Production Efficiency

Automate complex wrapping tasks and significantly increase your packaging throughput and consistency.

Join manufacturers worldwide who have upgraded to precision orbital wrapping technology.

Request Your Custom Solution

Project Overview & Advantages

Explore our specialized capabilities and successful case studies across various manufacturing sectors

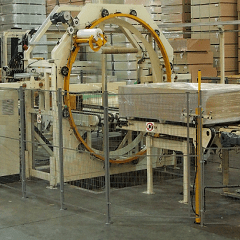

Customize orbital wrapper Manufacturing Excellence

A Customized Orbital Wrapper is tailored to meet specific packaging needs for irregular or unique-shaped products. Designed for precision and flexibility, it offers adjustable wrapping parameters, materials, and configurations. Ideal for industries with diverse packaging requirements, it enhances efficiency, protects products, and ensures consistent, high-quality packaging .

Semiauto horizontal wrapper

A Semi-Auto Horizontal Wrapper is a versatile packaging machine designed for wrapping elongated products like pipes, profiles, or panels. Combining manual and automated functions, it provides reliable wrapping with stretch film or other materials, ensuring product protection. Ideal for medium-scale operations, it offers flexibility, efficiency, and cost-effective packaging solutions.

Customize orbital wrapper

A Customized Orbital Wrapper is tailored to meet specific packaging needs for irregular or unique-shaped products. Designed for precision and flexibility, it offers adjustable wrapping parameters, materials, and configurations. Ideal for industries with diverse packaging requirements, it enhances efficiency, protects products, and ensures consistent, high-quality packaging .

Automatic horizontal stretch wrapper

An Automatic Horizontal Stretch Wrapper is an advanced packaging machine designed for efficiently wrapping long or irregularly shaped products, such as pipes, doors, or panels. Featuring automated film application and tension control, it ensures consistent wrapping quality. This machine enhances productivity, reduces material waste, and provides secure packaging for safe transport and storage.

Customized Orbital Wrapping Systems

Our bespoke orbital wrapping equipment delivers tailored packaging solutions for irregularly shaped and specialized industrial products, combining adaptive engineering with intelligent control systems to ensure perfect wrapping coverage and superior product protection.

Adaptive Configuration: Customizable wrapping patterns, speed controls, and film tension settings to match unique product geometries and protection requirements.

Multi-Material Compatibility: Engineered to work with various wrapping films including stretch film, shrink film, and specialized protective materials.

Smart Operation Interface: User-friendly PLC controls with preset programs and real-time monitoring for consistent wrapping quality across all production batches.

Packaging Time Reduction

Damage Prevention Rate

Material Waste Reduction

Product Configurations

Aerospace Component Protection Solution

Challenge Overview

A leading aerospace manufacturer required specialized packaging for delicate turbine components with irregular shapes, needing complete environmental protection during international shipping while minimizing packaging material usage.

Custom Engineering Solution

We developed a precision orbital wrapping system with adjustable rotation speed and programmable film overlap, specifically designed for fragile aerospace parts. The solution achieved 99.8% protection efficiency during transit testing and reduced packaging cycle time by 40% compared to previous manual methods.

Request Custom Solution Quote

SHOWCASE & NEWS

Custom Orbital Wrapping Solutions FAQ

Expert Answers to Your Custom Wrapping Equipment Questions

Customized orbital wrappers are engineered to handle unique product shapes and specialized packaging requirements that standard machines cannot accommodate. Unlike off-the-shelf solutions, our bespoke orbital wrapping systems feature adjustable rotation speeds, customizable film tension controls, and adaptable arm configurations. These machines can process irregular geometries, oversized items, and delicate products with precision. The customization extends to integration with existing production lines, specific safety requirements, and specialized material handling needs for various industrial applications.

Multiple sectors leverage custom orbital wrapping for specialized packaging needs. Aerospace companies use them for wrapping composite materials and aircraft components. Construction equipment manufacturers protect heavy machinery parts and structural elements. The marine industry wraps pipes, propellers, and ship components. Energy sector applications include transformer coils, turbine blades, and pipeline sections. Automotive manufacturers protect sensitive subassemblies and custom parts. Each industry benefits from tailored solutions that address specific product dimensions, weight distribution, and protective requirements during transit and storage.

Our custom orbital wrappers offer extensive modification capabilities including adjustable ring diameters from 500mm to 3000mm, variable rotation speeds from 5-30 RPM, and customizable film carriage movements. Additional options include heated film systems for enhanced adhesion, multiple film roll stations for automatic material changeover, integrated strapping units, and climate-controlled enclosures. Control systems can be tailored with programmable logic controllers, touchscreen interfaces, and recipe storage for different product types. Safety features like light curtains, emergency stops, and interlocking guards are customized to your facility's specific requirements.

The timeline for custom orbital wrapper implementation typically spans 10-16 weeks from initial consultation to operational commissioning. The process begins with a 2-3 week engineering assessment and design phase, followed by 6-8 weeks for manufacturing and assembly. Installation requires 1-2 weeks, with an additional week for testing, calibration, and operator training. Complex projects with unique specifications may extend this timeline. We provide detailed project management with regular progress updates and factory acceptance testing to ensure the customized equipment meets your exact specifications before shipment.

Our customized orbital wrapping systems accommodate diverse packaging materials including standard polyethylene stretch films, UV-resistant films for outdoor storage, vented films for moisture-sensitive products, and anti-static films for electronic components. Specialized options include reinforced films for heavy-duty protection, pre-stretched films for cost efficiency, and biodegradable materials for sustainable packaging. The machines can handle film widths from 500mm to 2000mm and roll diameters up to 400mm. Custom tension control systems ensure optimal film application regardless of material characteristics, providing consistent wrapping quality across different film types.

We provide comprehensive technical support beginning with detailed operator and maintenance training during commissioning. This includes hands-on instruction covering daily operation, routine maintenance, troubleshooting procedures, and safety protocols. Our support package features remote monitoring capabilities, 24/7 technical assistance, and access to our online knowledge base. Customers receive detailed documentation including operation manuals, maintenance schedules, and spare parts lists. We offer optional service contracts for preventive maintenance and rapid response support. Our global service network ensures prompt assistance regardless of your facility's location, minimizing potential downtime.

Our Clients Around The World

We are honored to serve outstanding enterprises worldwide, establishing long-term stable partnerships. Below are some of our trusted partners who have chosen our manufacturing solutions.

Ready to Start Your Next Manufacturing Project?

Impressed by our projects? If you have similar requirements or want to discuss your project ideas, contact our expert team immediately for a free initial consultation.

Contact Our Experts